Two-drum spraying denitration settling separation corner-tube boiler

A technology of settling separation and corner tube boilers, which is applied in the field of boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

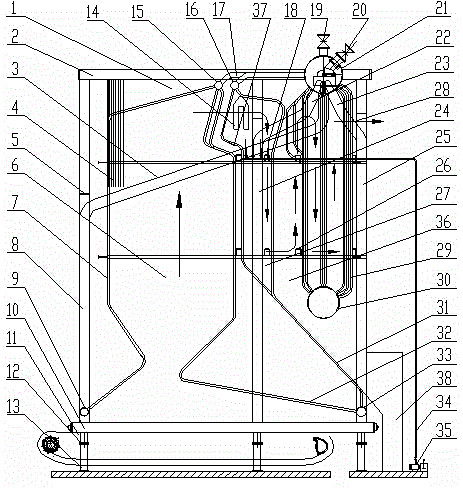

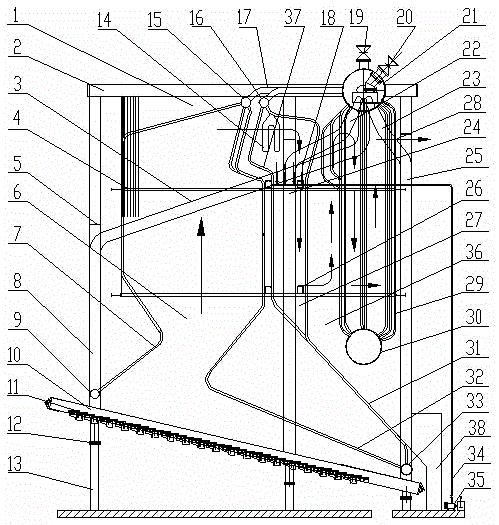

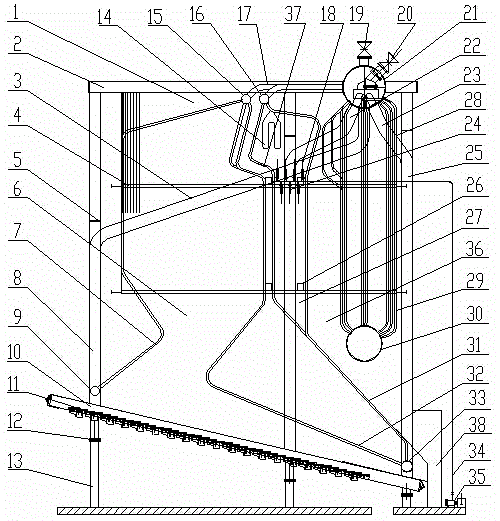

[0022] Specific embodiments of the present invention, such as Figure 1-4 As shown, a double-drum spray denitrification settlement separation angle tube boiler includes a boiler body part and a grate part. The boiler body part includes a boiler body 1, and four supporting boilers are vertically arranged around the boiler body 1. The left side supports the downcomer 8 and the right side of the boiler supports the rear arch feedwater downcomer 25, the upper drum 21 and the lower drum 30 arranged on the upper right part of the boiler body 1, and the convection tube bundle 29 between the upper drum 21 and the lower drum 30 , the water inlet pipe 20 and the water outlet pipe 19 connected with the upper drum 21, the front arch descending pipe 3 and the rear arch descending pipe 23, and the upper return pipe 17, the superheater 14, the side wall water cooling wall 4, the furnace 6, and the front arch water cooling wall 7. Front arch lower header 9, side wall water wall upper header 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com