Single-drum double-furnace composite combustion settling chamber angle tube boiler

A technology for burning settling chambers and corner tube boilers, applied in the boiler field, can solve problems such as low boiler strength, insufficient combustion, safety accidents, etc., and achieve the effects of improving thermal efficiency, simple structure, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

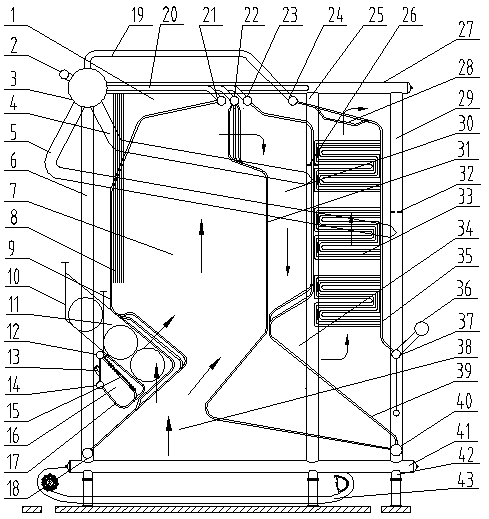

[0025] The invention provides a single-drum double-furnace composite combustion settling chamber corner tube boiler, such as figure 1 As shown, it includes the boiler body part and the combustion system part. Boiler furnace body part includes boiler body 1, six front side support downpipes 6 with supporting and descending functions vertically arranged around boiler body 1, middle support downpipe 25, throttle ring I26 and rear side support downpipe 29, throttling Circle II32, the drum 3 set on the upper part of the boiler body 1, the water inlet pipe 2 connected to the drum 3, the water supply pipe 19, the downcomer I4, the downcomer II5 and the upper return pipe 20, the upper header 27 on the side water wall, Side water wall 8, side water wall lower header 41, furnace I7, furnace II 38, front arch upper header 21, front arch water wall 9, front arch lower header 18, sealing plate 10, biomass combustion chamber 11, water Cold air chamber membrane wall header 12, air inlet 13,...

Embodiment 2

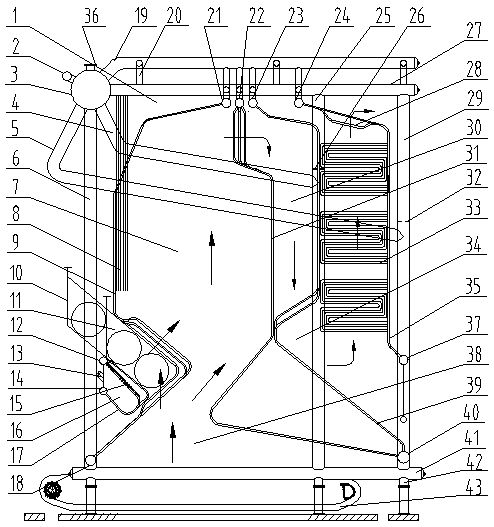

[0034] This embodiment is a further improvement made on the basis of Embodiment 1, including all the technical features of Embodiment 1, such as figure 2 As shown, the steam outlet is added on the drum 3, the water header 36 is replaced, the water supply pipe 19 in the main body is changed to the gas collecting pipe 19, and the combustion equipment is a chain grate.

Embodiment 3

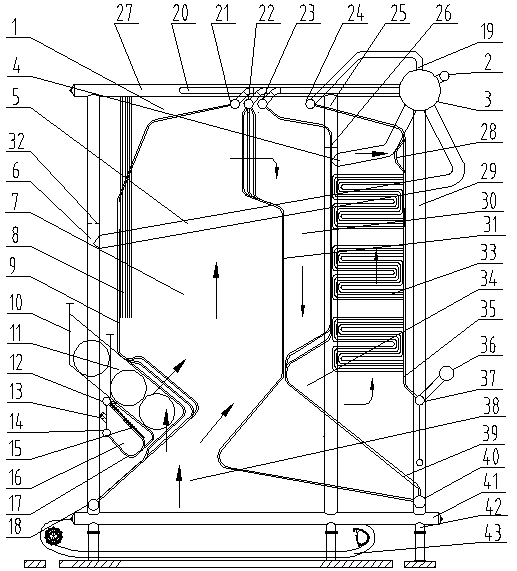

[0036] This embodiment is a further improvement made on the basis of Embodiment 1, including all the technical features of Embodiment 1, such as image 3 As shown, the drum 3 is on the upper right part of the boiler body 1, and the combustion equipment is a chain grate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com