Single-boiler-barrel transversely-arranging type reciprocating grate spraying and denitration corner-tube boiler

A technology of reciprocating grate and corner tube boilers, which is applied to water tube steam boilers, boiler water pipes, steam boilers, etc., to achieve the effects of reducing air and dust pollution, reducing emissions, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

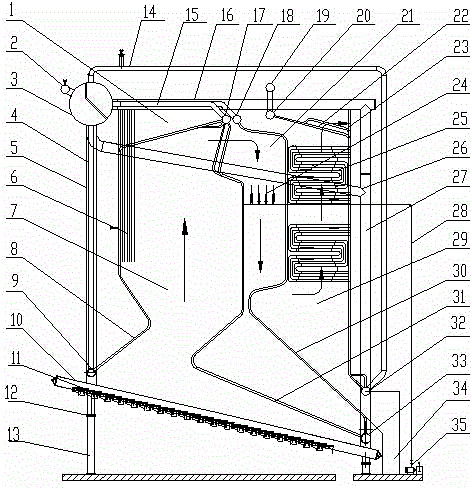

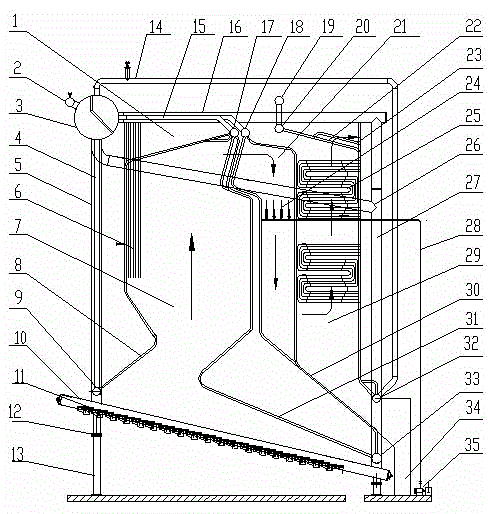

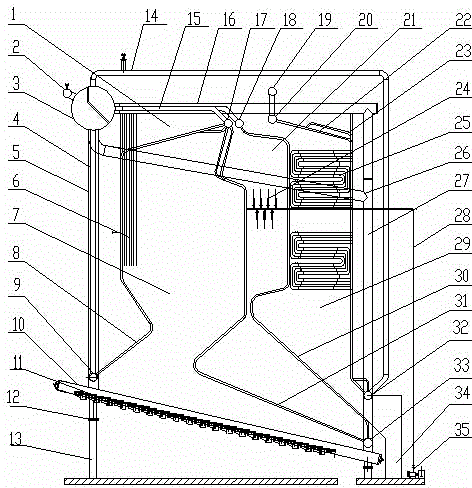

[0022] Specific embodiments of the present invention, such as Figure 1-5 As shown, a single-drum horizontal reciprocating grate spray denitrification corner tube boiler includes a boiler body part and a reciprocating grate part. The boiler body part includes a boiler body 1. The supporting side water wall downpipe 5 and the rear arch water supply pipe 27, the drum 3 arranged on the upper left part of the boiler body 1, the water inlet pipe 2 connected with the drum 3, the flag type heating surface water supply pipe 14, and the front arch downpipe 4, and downpipe 26 and upper return pipe 15, side wall water cooling wall 6, furnace 7, front arch water cooling wall 8, front arch lower header 9, side water cooling wall lower header 10, side wall water cooling wall upper header 16 , header 17 on the front and rear arches, outlet pipe 19, header 20 on the flag-type heating surface ,Flag-type heating surface tube 22, flue gas outlet 23, flag-type heating surface 25, rear arch water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com