Novel layer burning boiler

A boiler, a new type of technology, applied in the field of new layer fired boilers, can solve the problems of reduced heat absorption capacity of the heating surface, increased pollution emissions, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

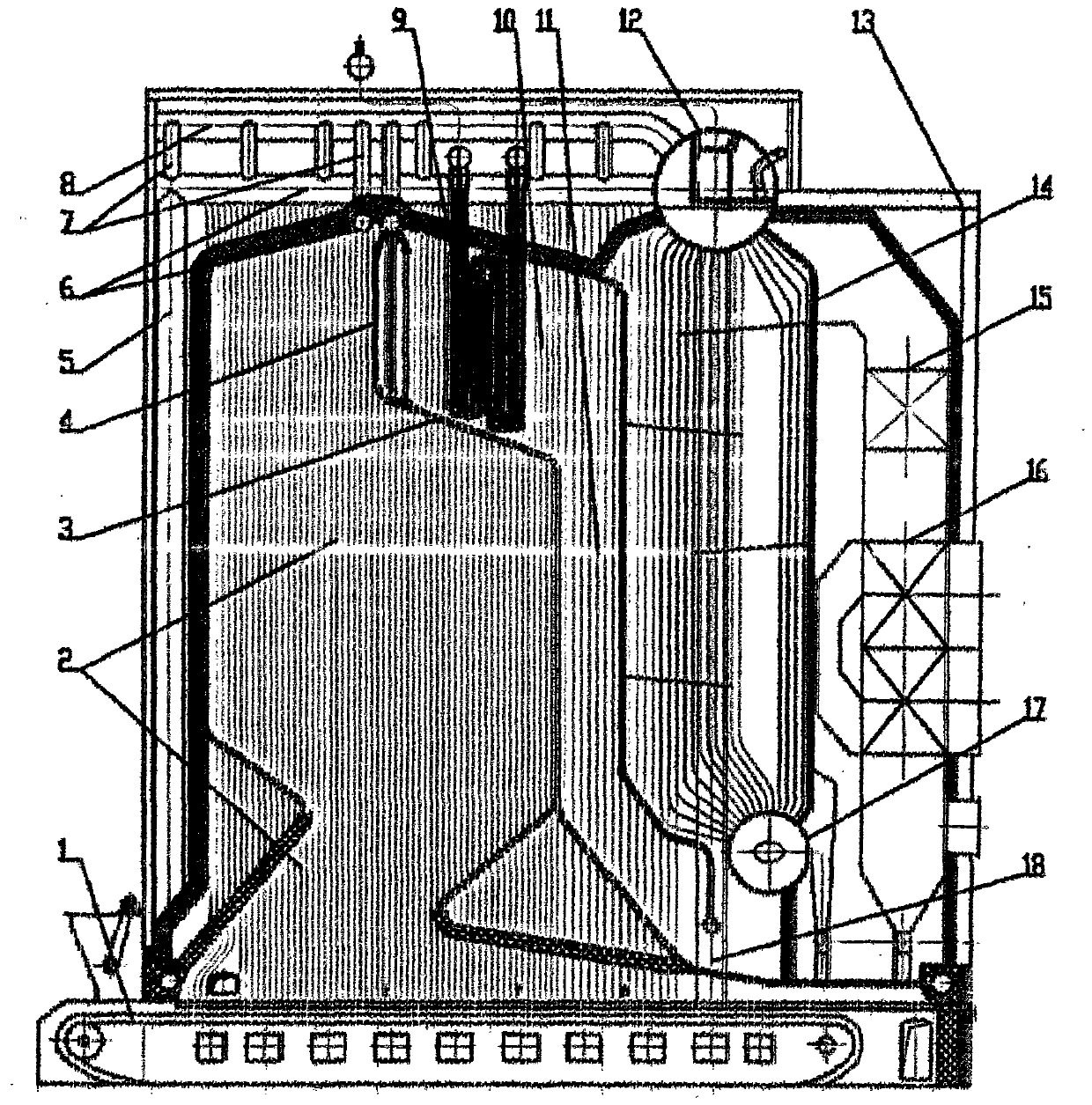

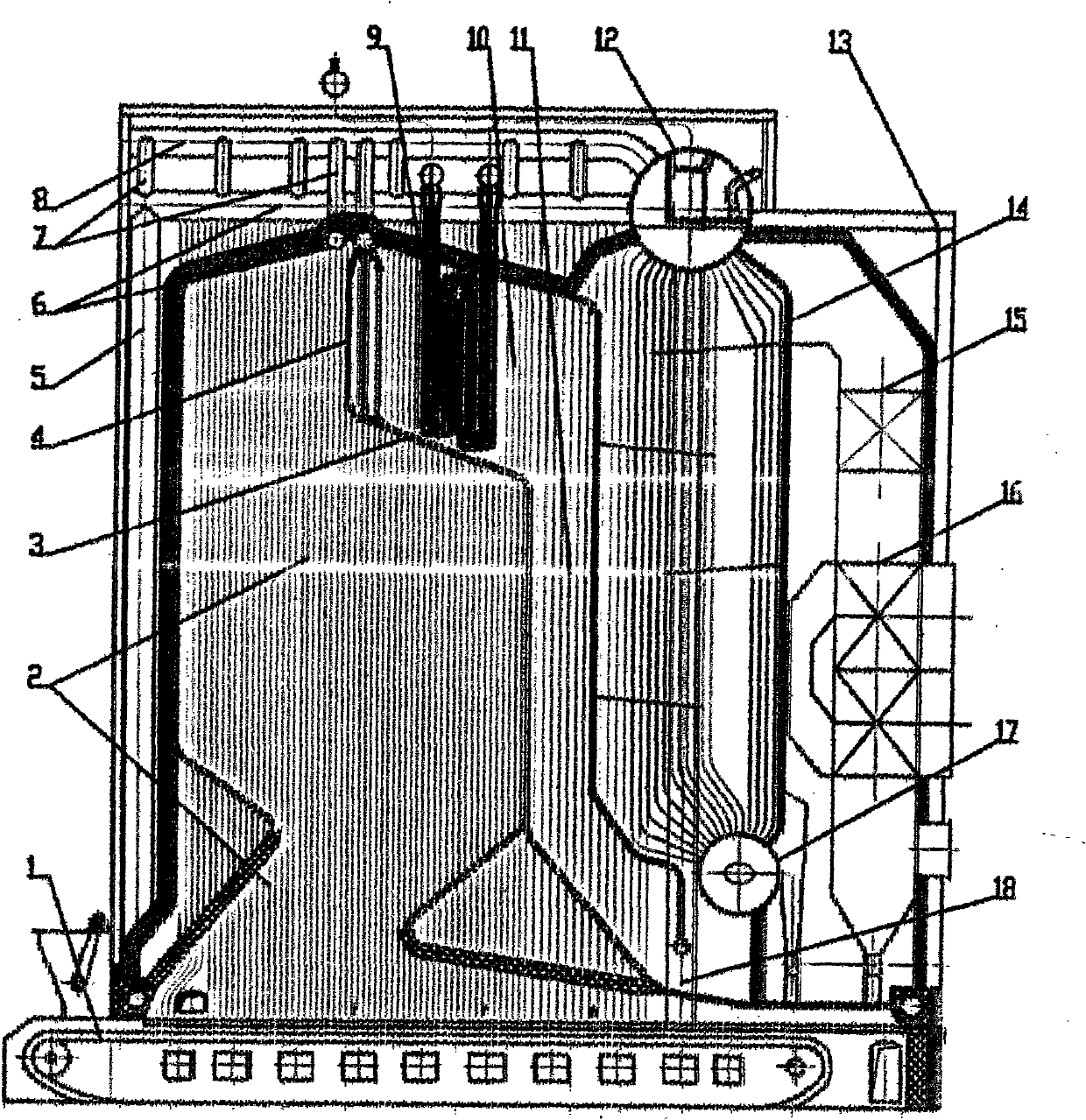

[0012] Such as figure 1 The hearth of a new type of layer-fired boiler shown here adopts the hearth structure of a corner tube boiler, and the main convective heating surface adopts a boiler tube bundle structure. There are at least 4 vertical water-cooled connecting pipes arranged around the boiler furnace, and a large number of boiler tube bundle heating surfaces are arranged between the upper and lower drums of the boiler.

[0013] The furnace smoke outlet of a new type of layer-fired boiler is set above the middle of the furnace, and returns to the middle of the furnace from the front of the water-cooled wall tube on the rear wall, and then pulls upward to form the slag pipe at the outlet of the furnace. The furnace outlet slag tube is located in the front and rear direction of the boiler, within the middle third of the furnace front and rear direction, and the angle between the water wall tube on the rear wall and the water wall tube returning to the middle of the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com