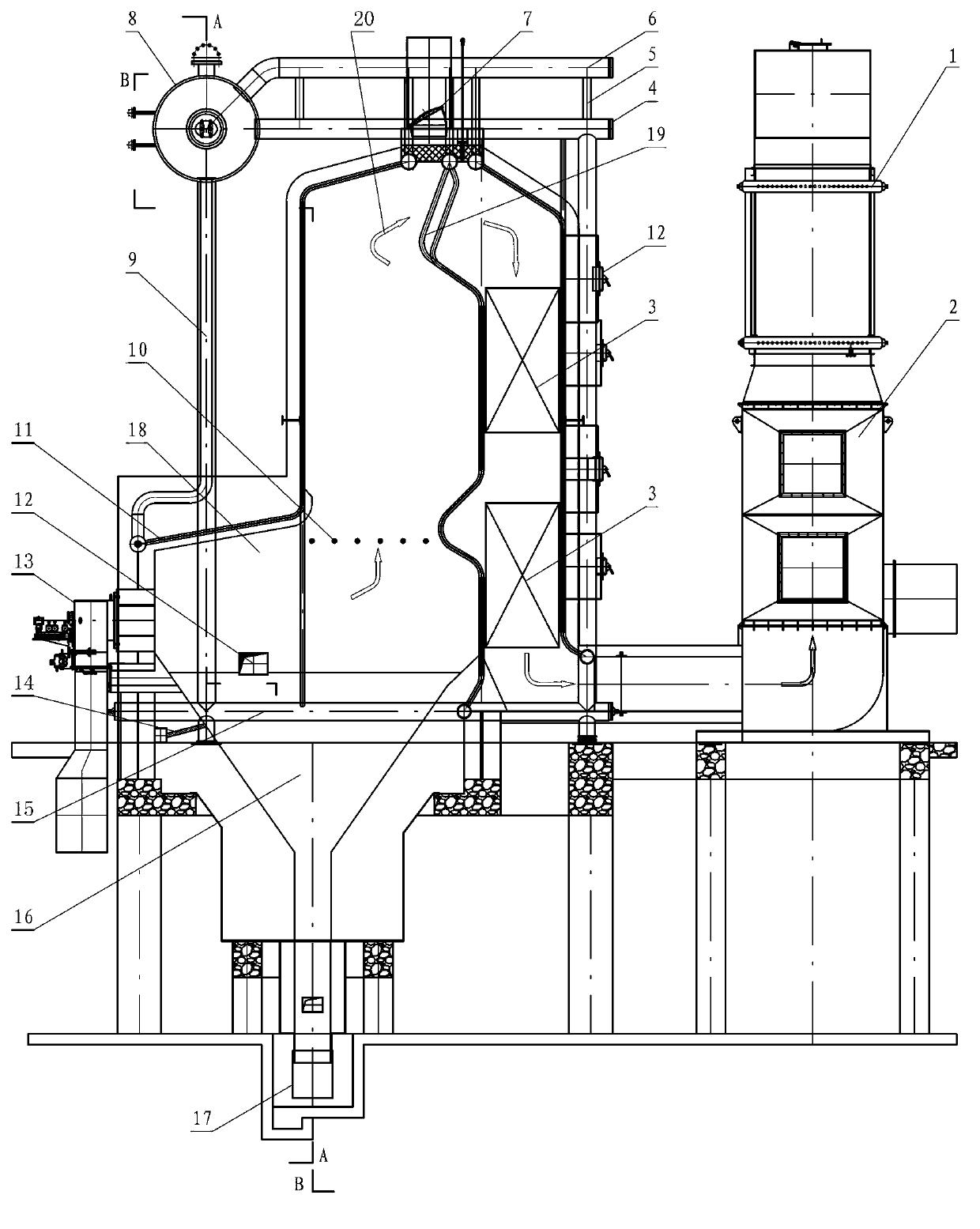

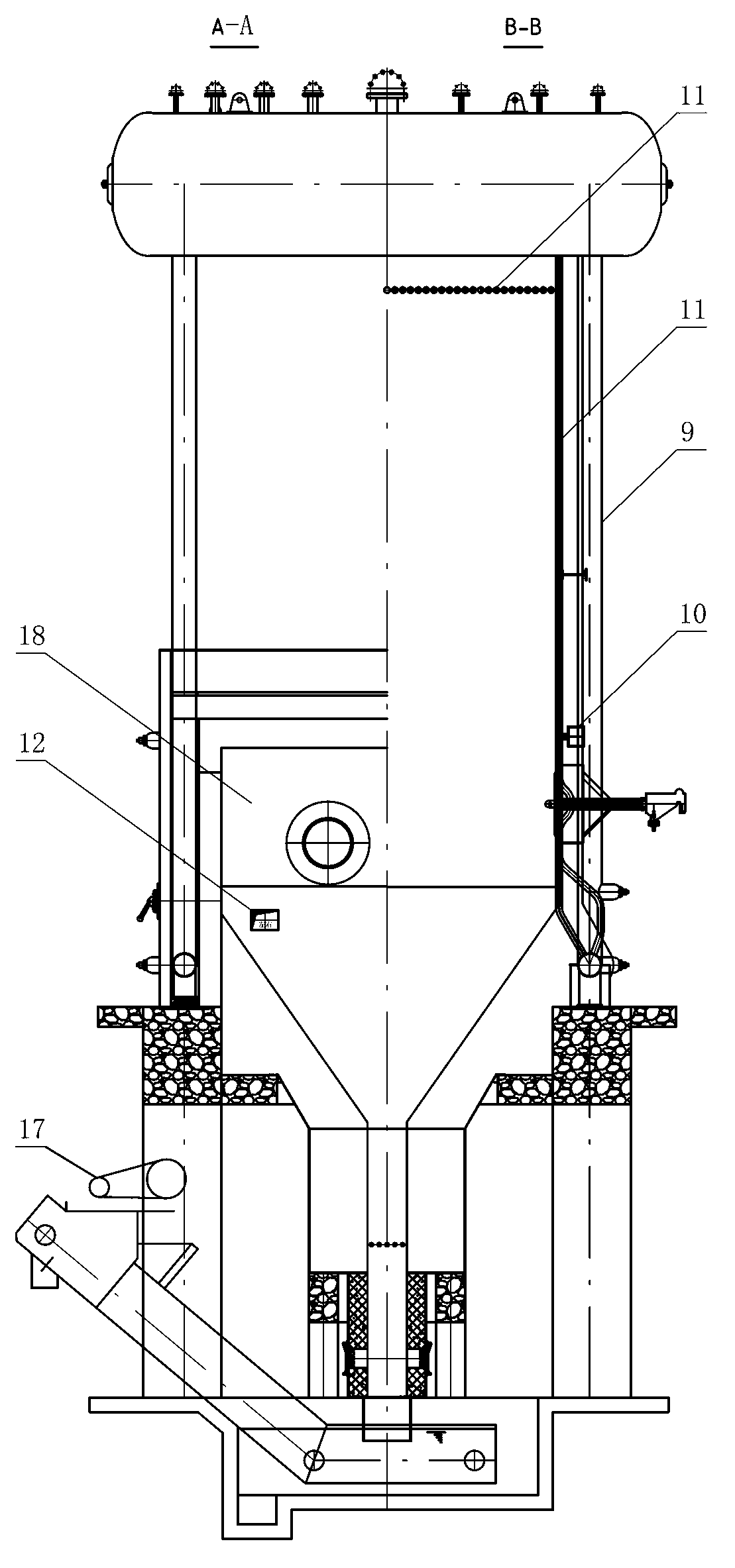

Vertical type modular coal water slurry corner tube boiler

A modular, coal-water slurry technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve problems such as poor boiler sealing performance, reduce NOX content, and uneven combustion, and achieve safe and reliable water circulation , Simple layout and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Referring to the accompanying drawings, a vertical modular coal-water slurry corner-tube boiler of the present invention includes a boiler body, a furnace (20), a burner (13), a combustion chamber (18), a cold ash hopper (16), Air preheater (2), economizer (1), convection tube bundle (3), upper header (4), top header (6), drum (8) and lower header (15), the The lower header (15) is set at the lower part of the boiler body; the upper header (4) and the top header (6) are set at the top of the boiler body, and communicated through the steam connecting pipe (5); it is characterized in that The combustion stabilization chamber (18) is arranged at the lower front of the boiler body; the burner (13) is arranged at the front wall of the combustion stabilization chamber (18); the boiler body includes four The downcomer (9) and the membrane water wall (11); the two ends of the downcomer (9) and the membrane water wall (11) are respectively connected to the upper header (4) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com