Chain-grate spraying and denitrifying corner tube boiler with horizontal single boiler barrel

A corner tube boiler, horizontally placed technology, applied in the direction of combustion product treatment, combustion method, removal of solid residue, etc., to achieve sufficient reaction time, eliminate the effect of returning materials and terminating boiler coking accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

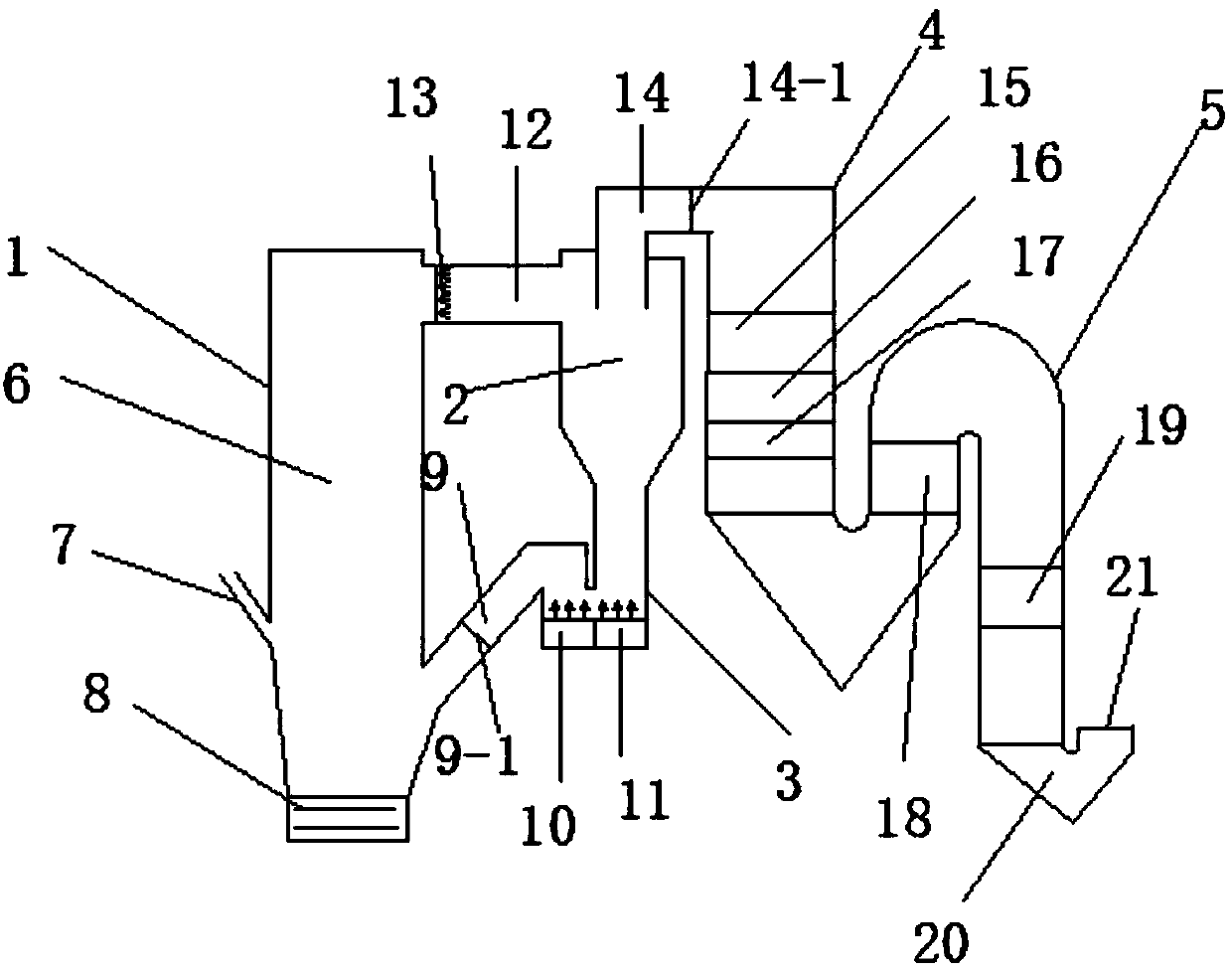

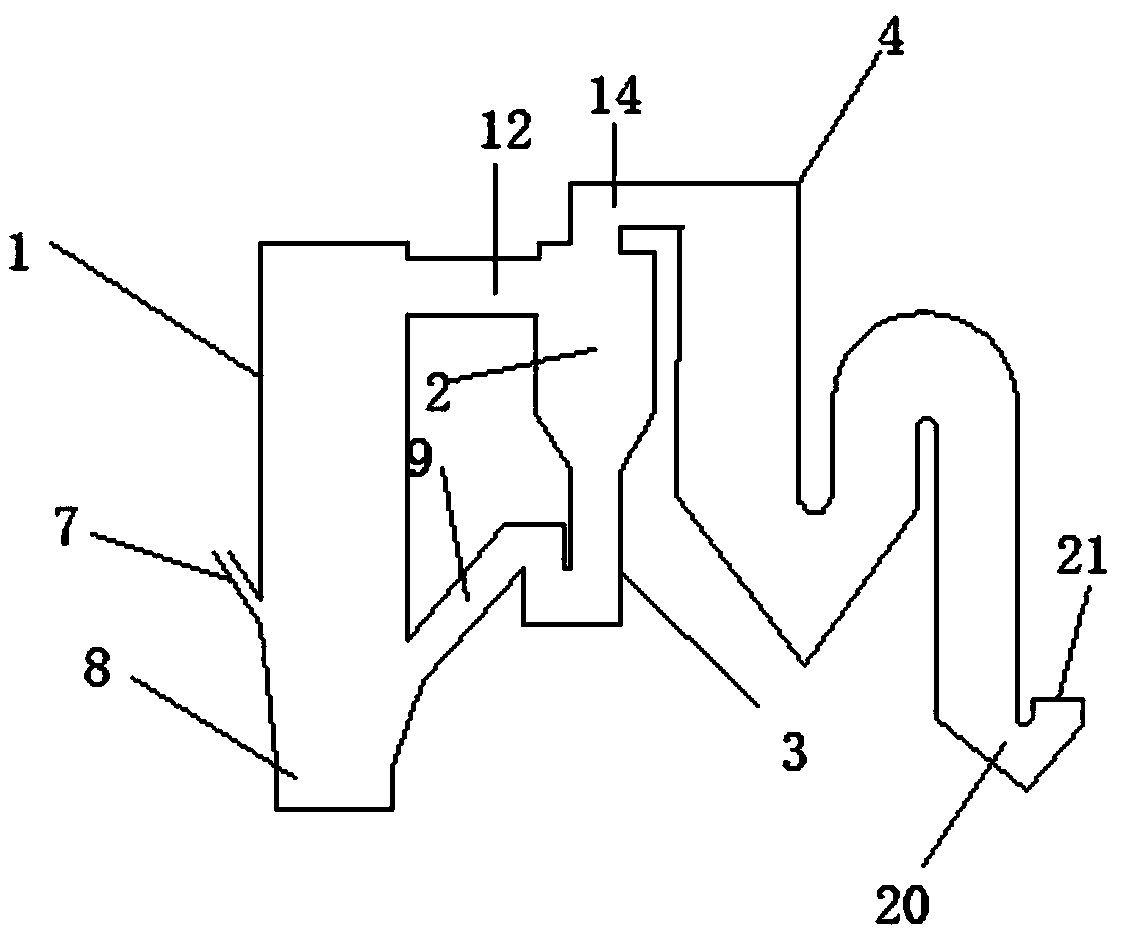

[0015] see figure 1 , figure 2 , the present invention provides a single-drum horizontal chain grate spraying denitrification angle tube boiler technical scheme: its structure includes a boiler 1, a cyclone separator 2, a U-shaped feeder 3, a treatment area 4, and an exhaust pipe 5, The boiler 1 is connected to the cyclone separator 2 through a convection flue 12, the U-shaped feeder 3 is connected to the boiler 1 through a return flue 9, and the treatment area 4 is connected to the cyclone separator 2 through a flue outlet 14 , the exhaust pipe 5 is connected to the treatment area 4 by welding, the boiler 1 includes a furnace 6, a coal feeding point 7, and an air chamber 8, the coal feeding point 7 is connected to the furnace 6, and the air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com