High-frequency pulse direct-current oscillation charging system controlled by PLC programming

A high-frequency pulse and pulse direct current technology, applied in charging stations, electric vehicle charging technology, current collectors, etc., can solve problems such as the decline in acceptable current capacity, inability to achieve high-efficiency charging, and battery plate bending, so as to increase the charging current Acceptance rate, improvement of charge acceptance, effect of ohmic polarization elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

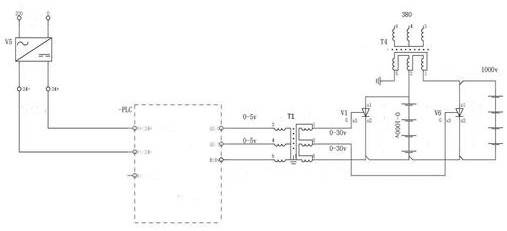

[0023] like figure 1 , the present invention is a high-frequency pulse DC oscillating charging system controlled by PLC programming, the charging system is provided with a high-frequency pulse control output module, a three-phase transformer T4 for AC boost, and a high-frequency pulse charging module;

[0024] The three-phase transformer T4 includes an input coil and two output coils, and the input coil of the three-phase transformer is electrically connected to a 380V AC input power supply and forms a current loop;

[0025]The high-frequency pulse control output module includes a PS switching power supply V5, a programmable logic controller PLC, and a pulse step-up transformer T1. The input end of the PS switching power supply is electrically connected to a 220V AC input power supply and forms a current loop. The PS switch The power supply is provided with at least a rectifier, which outputs 24V direct current to supply power to the PLC programmable controller. The power inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com