Denitrification method using decomposing furnace and decomposing furnace

A calcining furnace and denitration technology, applied in the field of cement industry, can solve the problems of unsatisfactory denitration effect of calcining furnace, high cost, complicated equipment, etc., and achieve the effect of improving material utilization rate, reducing the risk of skinning, and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

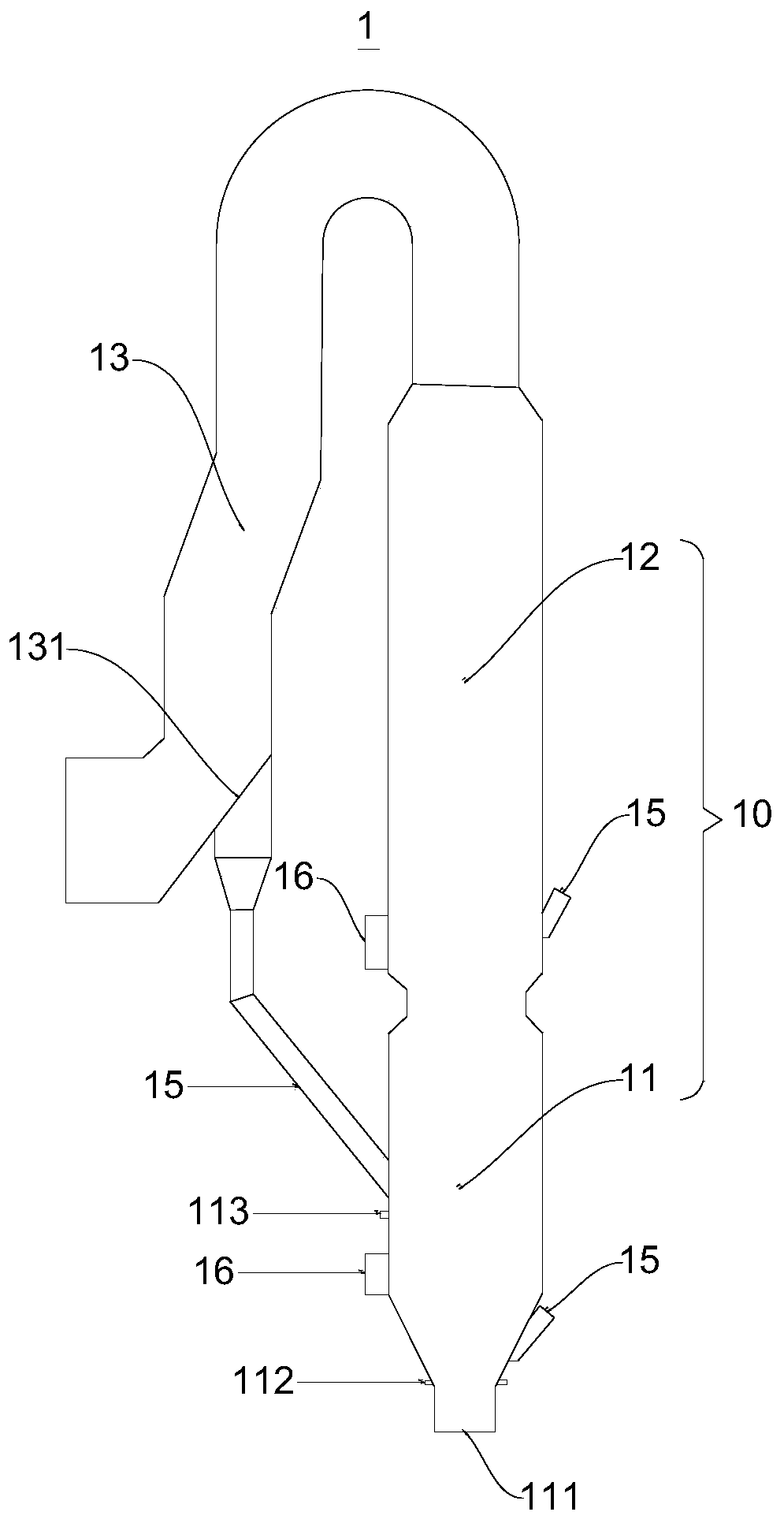

[0051] This embodiment provides a method for denitrification using a decomposition furnace, which includes the following steps:

[0052] Pulverized coal for reduction is injected from the lower end of the decomposition furnace and burned under anoxic conditions to prepare an oxygen-deficient reducing atmosphere, and pulverized coal for oxygen consumption is injected from the upper end of the decomposition furnace and burned to consume part of the oxygen at the upper end of the reducing atmosphere. The mass ratio of pulverized coal for reduction to pulverized coal for oxygen consumption is 4:1.

[0053] Inject two tertiary air into the calcining furnace, one of which is introduced from the lower end of the calcining furnace, and the other is introduced from the upper end of the calcining furnace. The volume ratio of the tertiary air entering the lower end to the tertiary air entering the upper end is 5:95.

[0054] The preheated cement raw meal is put into the decomposition furnace f...

Embodiment 2

[0059] This embodiment provides a method for denitrification using a decomposition furnace, which includes the following steps:

[0060] Pulverized coal for reduction is injected from the lower end of the decomposition furnace and burned under anoxic conditions to prepare an oxygen-deficient reducing atmosphere, and pulverized coal for oxygen consumption is injected from the upper end of the decomposition furnace and burned to consume part of the oxygen at the upper end of the reducing atmosphere. The mass ratio of pulverized coal for reduction to pulverized coal for oxygen consumption is 1:1.

[0061] Inject two tertiary air into the calcining furnace, one of which is introduced from the lower end of the calcining furnace, and the other is introduced from the upper end of the calcining furnace. The volume ratio of the tertiary air entering the lower end to the tertiary air entering the upper end is 45:55.

[0062] The preheated cement raw meal is put into the decomposition furnace ...

Embodiment 3

[0067] This embodiment provides a method for denitrification using a decomposition furnace, which includes the following steps:

[0068] Pulverized coal for reduction is injected from the lower end of the decomposition furnace and burned under anoxic conditions to prepare an oxygen-deficient reducing atmosphere, and pulverized coal for oxygen consumption is injected from the upper end of the decomposition furnace and burned to consume part of the oxygen at the upper end of the reducing atmosphere. The mass ratio of pulverized coal for reduction to pulverized coal for oxygen consumption is 2.6:1.

[0069] Inject two tertiary air into the calcining furnace, one of which is introduced from the lower end of the calcining furnace, and the other is introduced from the upper end of the calcining furnace. The volume ratio of the tertiary air entering the lower end to the tertiary air entering the upper end is 1:10.

[0070] The preheated cement raw meal is put into the decomposition furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com