Vertical type coal dust corner tube boiler

A corner-tube and vertical technology, applied in the field of vertical pulverized coal corner-tube boilers, can solve the problems of reducing NOX content, inconvenient cleaning of boiler ash and slag, and large boiler room area. The effect of uniform air volume, safe and reliable water circulation, and lower boiler cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

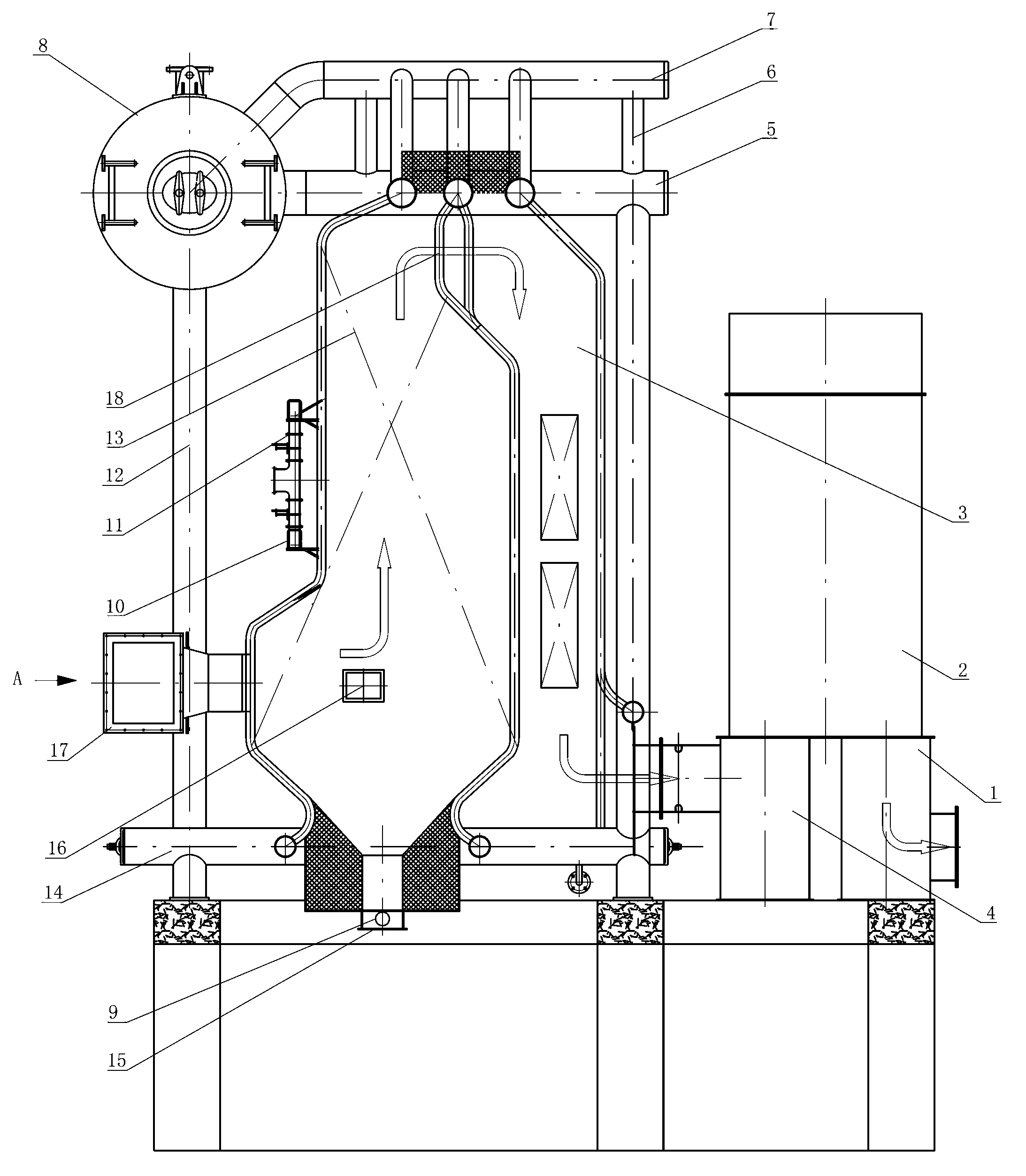

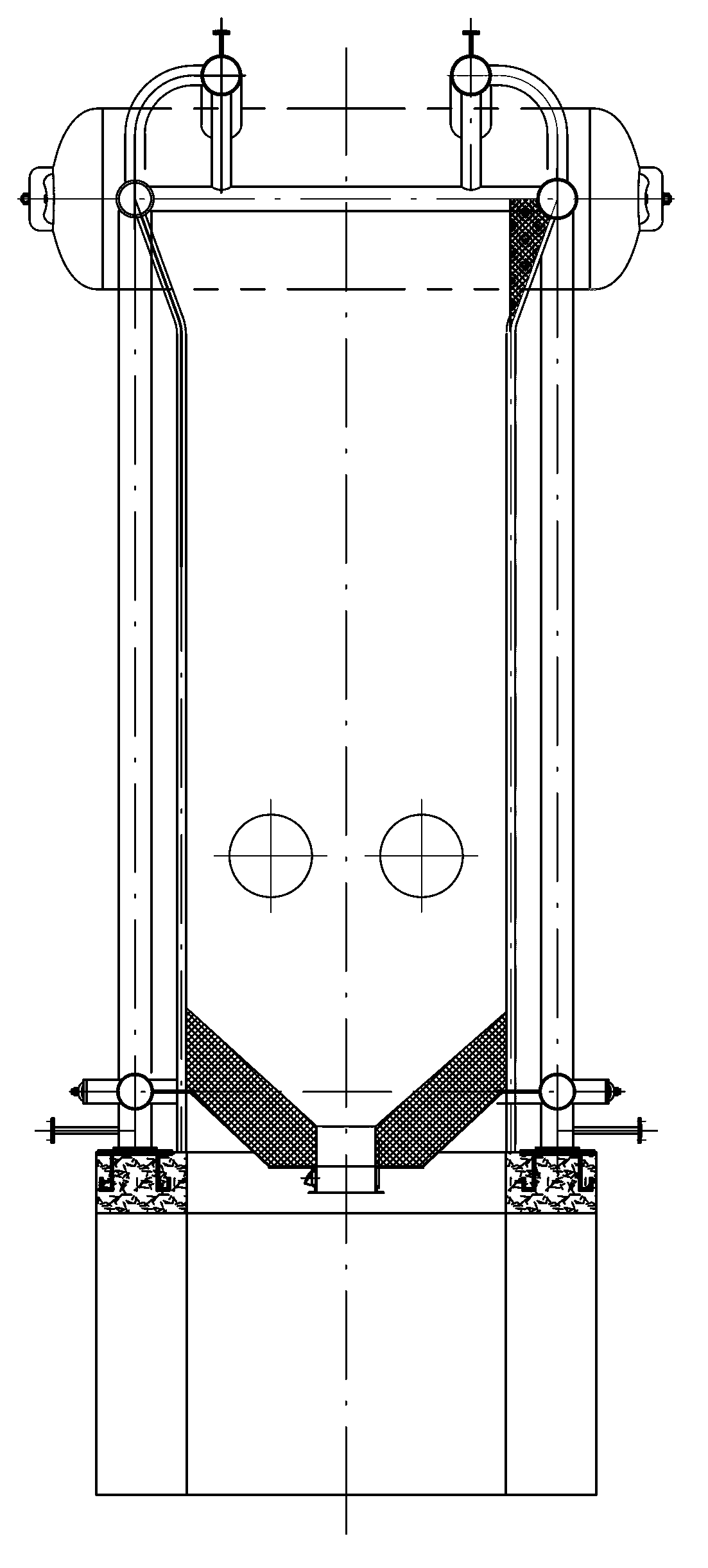

[0031] refer to figure 1 , a vertical pulverized coal corner tube boiler, including two burners 17, a boiler furnace 13, a high-temperature air preheater 4, an economizer 2, a low-temperature air preheater 1, a convection tube bundle 3, and an upper header 5 , top header 7, drum 8 and lower header 14, the lower header 14 is arranged on the bottom of the boiler body, the upper header 5 and the top header 7 are arranged on the top of the boiler body, and pass The steam connecting pipe 6 is connected; the burner 17 is arranged at the front of the boiler body; the boiler body adopts a vertical membrane water wall structure, and four downcomers 12 are arranged at the four corners, and the downcomer 12 and the membrane type Both ends of the water-cooled wall communicate with the upper header 5 and the lower header 14 respectively; the convection tube bundle 3 adopts flag plane tubes, and is arranged vertically on the outside of the membrane-type water-cooled wall, and the convection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com