Large garbage treatment machine

A large-scale technology for garbage disposal, applied in the field of large-scale garbage disposal machines, which can solve the problems of waste and can no longer be used, and achieve the effect of eliminating the need for workshops, facilitating disassembly and transportation, and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

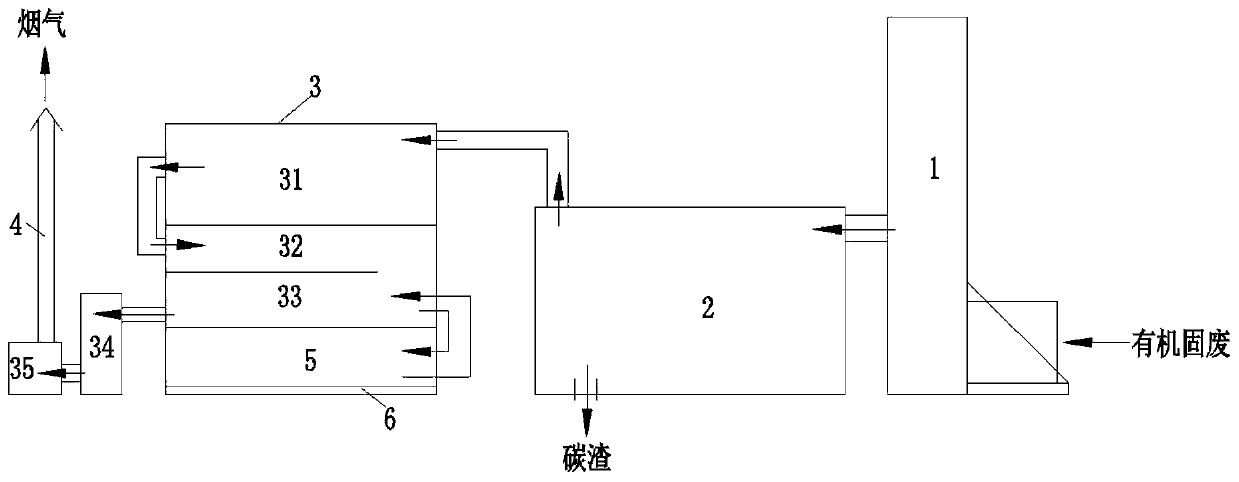

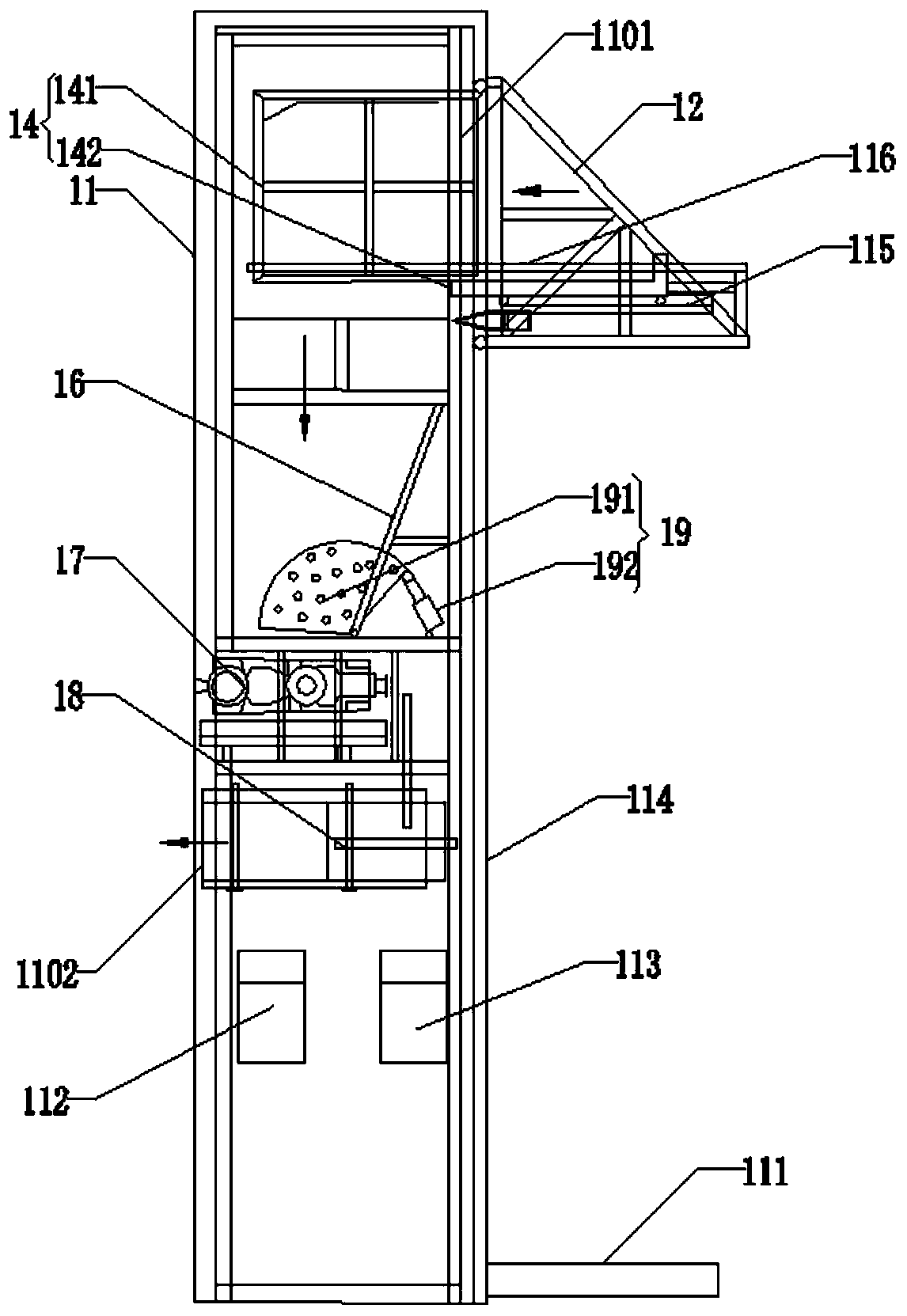

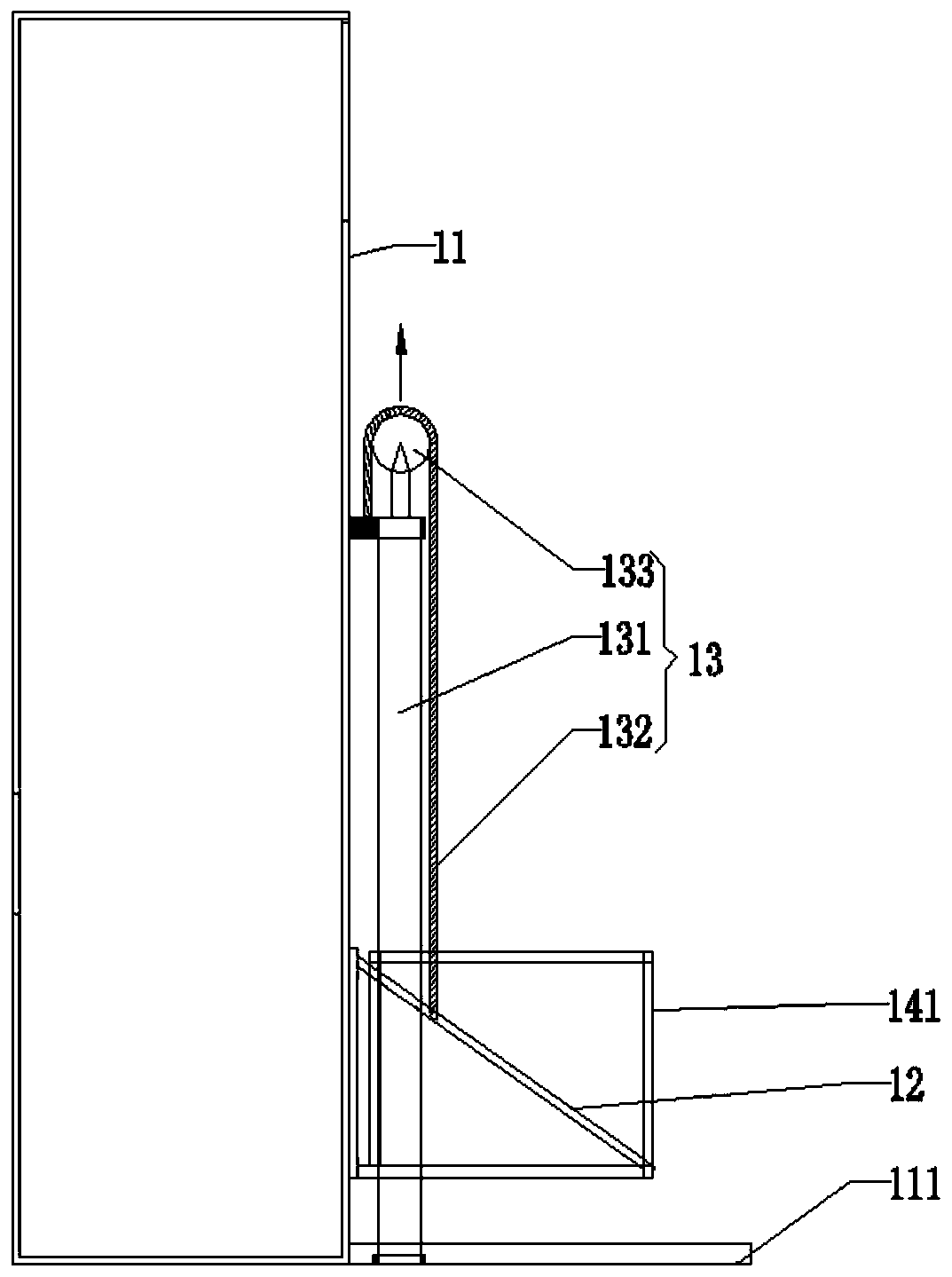

[0062] Such as Figure 1-Figure 28 As shown, this embodiment provides a large-scale garbage disposal machine, including a sequentially connected feeding device 1, an assembled pyrolysis gasifier 2, an exhaust gas treatment device 3 and a chimney 4, and the tail gas treatment device 3 includes two sequentially connected Combustion, rapid cooling and heat exchange box 31, dust removal, desulfurization and denitrification box 32, and wet electrostatic precipitator and mist removal box 33. The outlet 2212 communicates, and the outlet of the wet electrostatic precipitator and mist removal box 33 communicates with the chimney 4 .

[0063] Specifically, the dust removal, desulfurization and denitrification box 32 includes a first container and a spray pipe arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com