Corner tube boiler capable of being used for SCR denitration

An angle-tube boiler and denitration technology, which is applied in the field of boilers, can solve the problems of affecting the emission index of the boiler, low load, and the flue temperature of the denitration window cannot meet the minimum requirements of the denitration temperature, etc., and achieves the effect of meeting the environmental protection emission requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

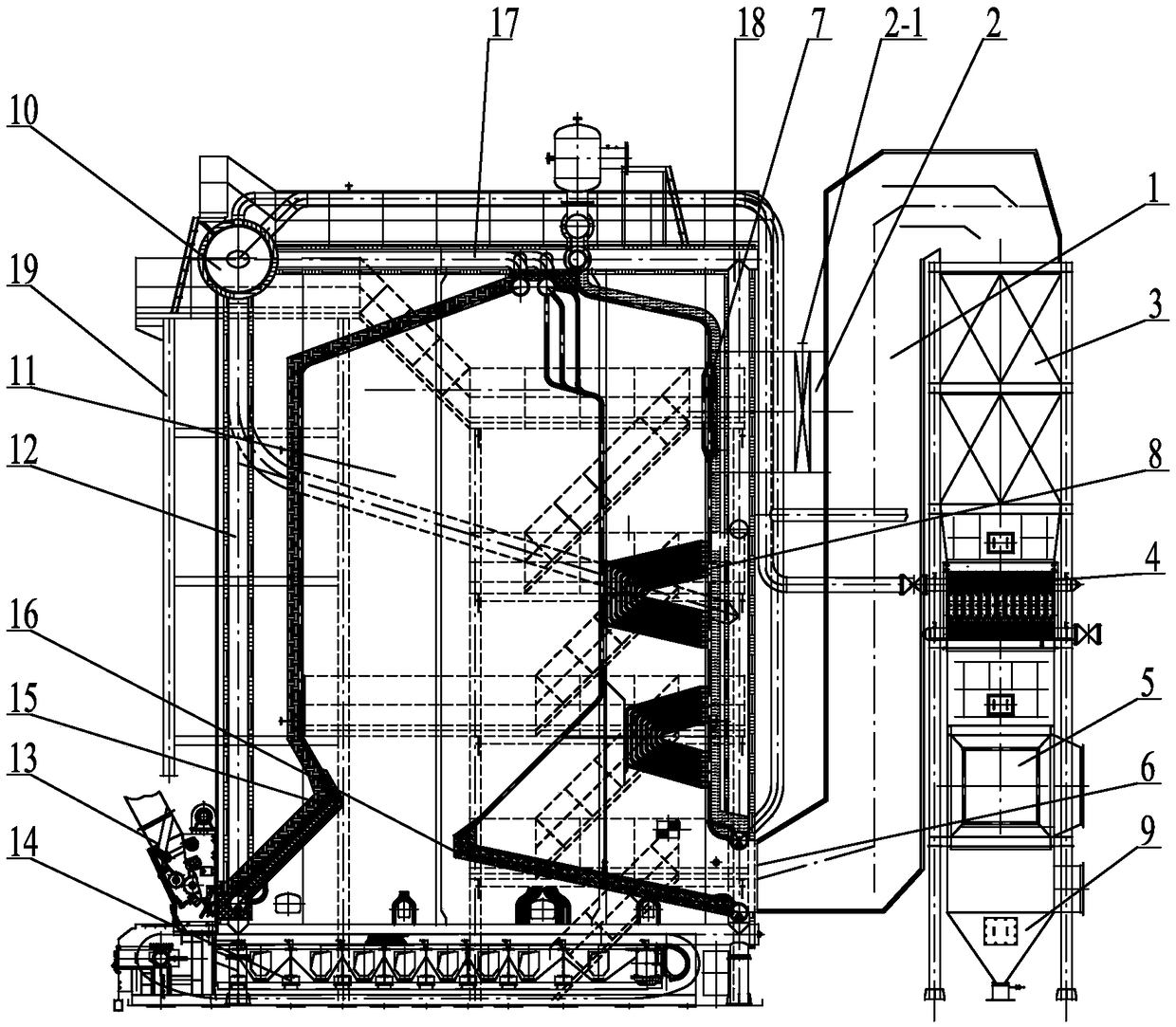

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment. A corner tube boiler that can be used for SCR denitrification described in this embodiment includes a boiler body and a smoke exhaust mechanism. The smoke exhaust mechanism includes a connecting flue 1, a high-temperature bypass flue 2, an SCR denitrification reactor 3, The economizer 4 and the air preheater 5 are connected to the inlet end of the flue 1 and the low-temperature flue gas exhaust port 6 of the boiler body, and the low-temperature flue gas exhaust port 6 is arranged behind the flag-type convection screen 8 in the boiler body The other end connected to flue 1 is provided with SCR denitrification reactor 3, economizer 4 and air preheater 5 sequentially from inside to outside. The smoke port 7 is connected, the high temperature flue gas exhaust port 7 is set at the front end of the flag type convection screen 8 in the boiler body, the outlet end of the high temperature bypass flue 2 ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 To describe this embodiment, the high-temperature bypass flue 2 in this embodiment is provided with a flue gas regulating valve 2-1. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0014] Such a design can adjust the flow rate of the high-temperature flue gas in the high-temperature bypass flue 2 according to the actual temperature of the flue gas entering the connecting flue 1, so that the mixed flue gas meets the denitrification reaction temperature.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 To describe this embodiment, a temperature sensor is provided at the upper end of the SCR denitration reactor 3 described in this embodiment. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

[0016] In this design, the temperature sensor is used to monitor the flue gas temperature at the upper end of the SCR denitrification reactor 3. When the temperature is lower than 320°C, a signal is sent to the controller, and the operator opens the flue gas regulating valve 2-1 through the controller to introduce high-temperature flue gas; When the flue gas temperature meets the denitrification temperature, the temperature sensor sends a signal to the controller, and the operator closes the flue gas regulating valve 2-1 through the controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com