Three-return-stroke powder steam boiler

A steam boiler, three-return technology, applied in steam boilers, steam generation, fluidized bed combustion equipment, etc., can solve the problems of large temperature difference between front and rear, short flue gas flow, high civil construction cost, and reduce the production of nitrogen oxides, Improve heat exchange efficiency, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

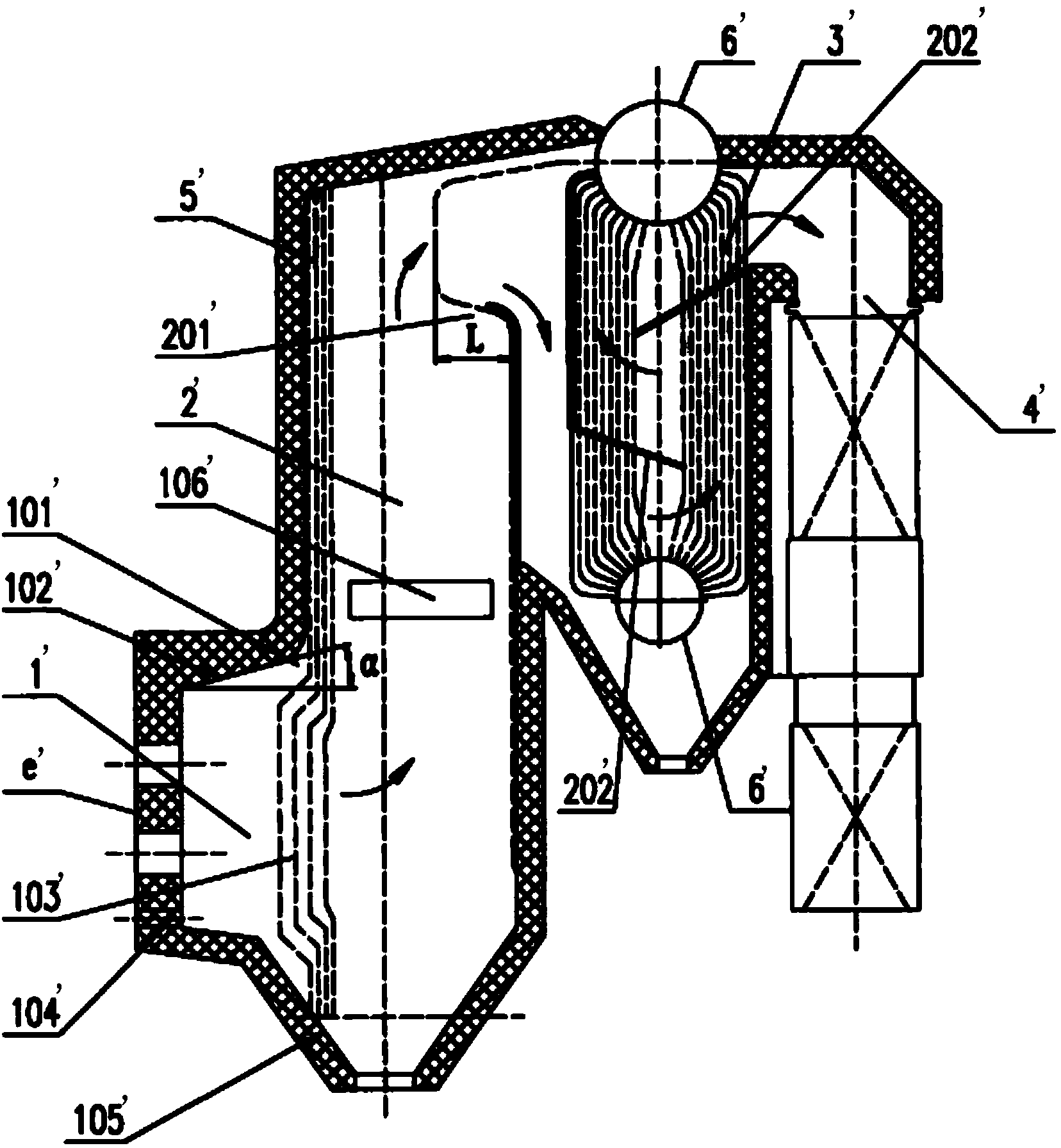

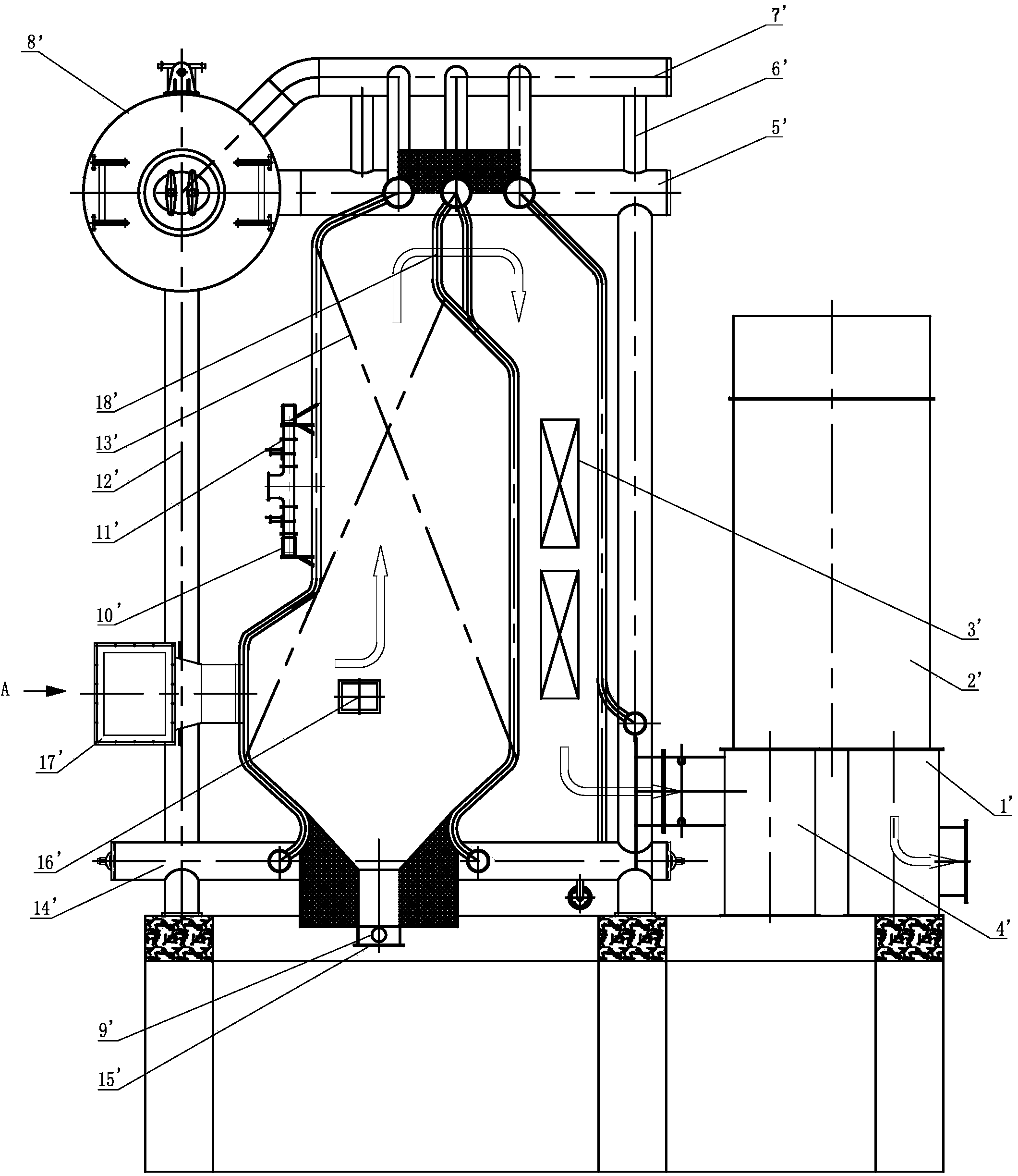

[0037] refer to figure 1 and figure 2 , the defects of the existing vertical pulverized coal corner tube boilers have been described above, and will not be repeated here.

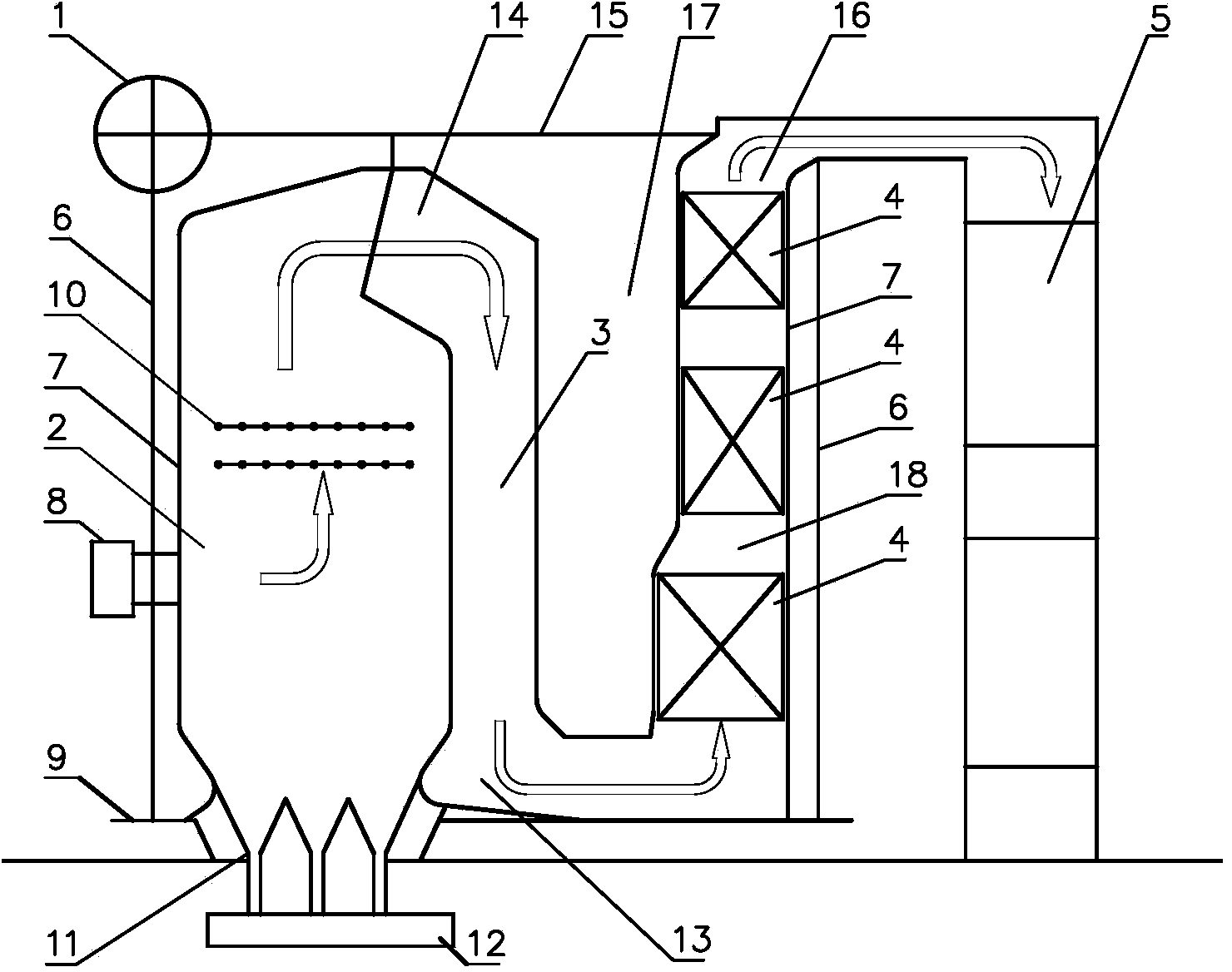

[0038] refer to image 3 , the first embodiment of the present invention. In this embodiment, the burner is arranged at the front of the furnace.

[0039] A three-pass powder steam boiler of the present invention includes a drum 1, a furnace 2, a burnout chamber 3, a convection tube bundle 4, a tail heat exchange device 5, a burner 8, a slag removal device 11, a lower header 9 and an upper header box 15, the lower header 9 is set at the bottom of the boiler body, the upper header 15 is set at the top of the boiler body; the burner 8 is arranged at the front of the boiler furnace; the boiler body Full-membrane water wall is adopted, and corner tube or tube frame structure is adopted at the same time, four main downcomers 6 are arranged at the four corners; the convection tube bundle 4 adopts a flag surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com