Full-automatic wood door lock, hinge groove and hole processor

A fully automatic, hole processing technology, applied in the field of hole processing machines and grooves, it can solve problems such as unsatisfactory work efficiency and automation, and no hinge grooves have been found, and can solve processing problems, grooving quality and machining accuracy. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

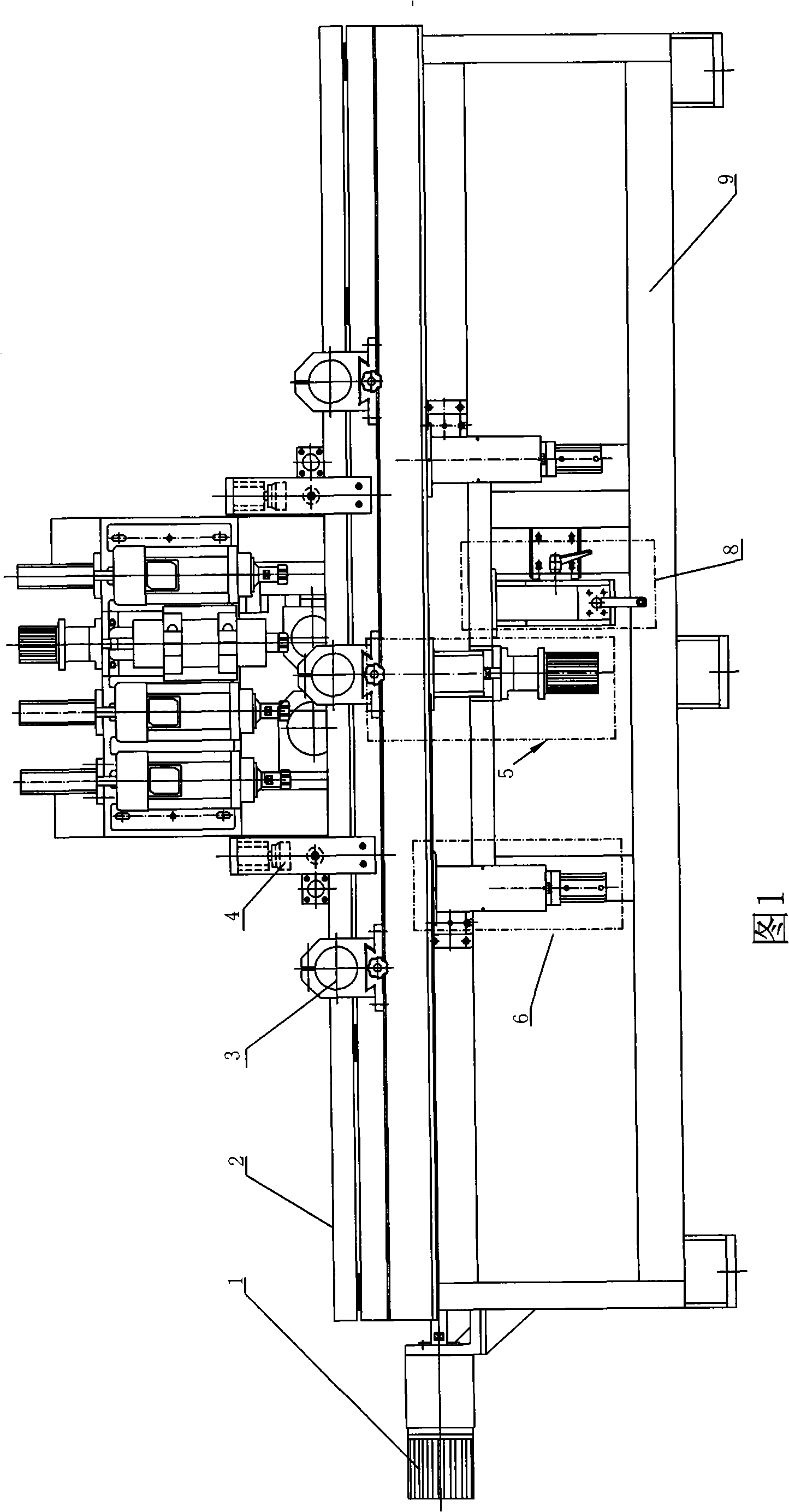

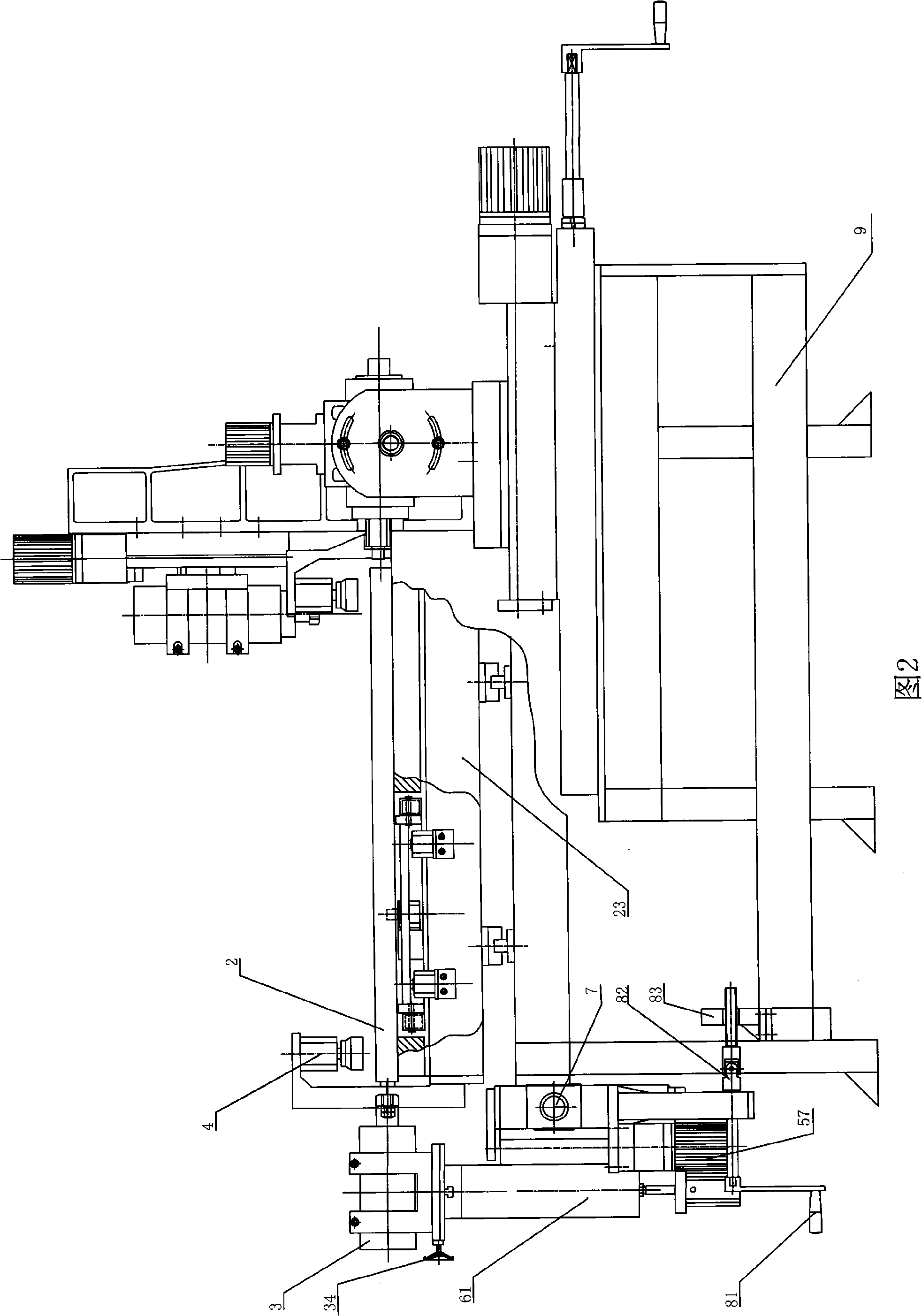

[0026] With reference to Fig. 1, Fig. 2, this full-automatic wooden door lock, hinge processing machine comprises frame 9, the workbench 23 that is moved horizontally by the control of servo motor 1, and workbench and frame 9 slide fit, and the wooden door 2 that is processed is flat Placed on the workbench 23, the frame on the side of the workbench is equipped with a plurality of wooden door pneumatic clamping devices 4, and three left, middle and right hinges that can move relative to the frame and have adjustable pitch angles are specially used for opening hinges. Slot electric milling cutter device3. Mount elevating device 5 and pitch device 8 are installed below the frame of the electric milling cutter device in the middle, and the balance device 6 of electric milling cutter device is installed below the frame of two electric milling cutter devices on the left and right.

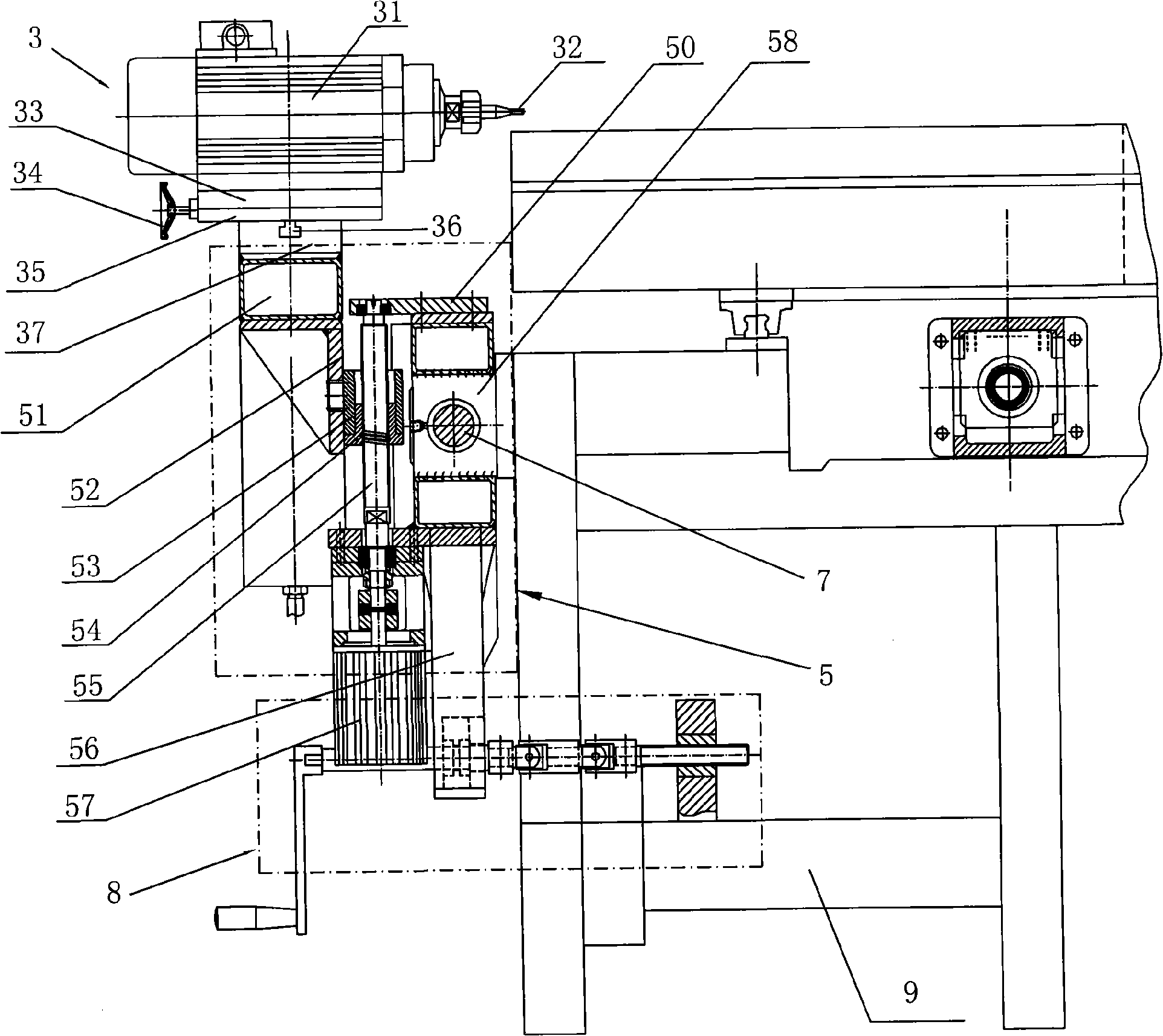

[0027] refer to image 3 , the electric milling cutter device is installed on the seat frame device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com