Five-axis multi-functional thread grinding machining center

A thread grinding and machining center technology, applied in the field of CNC machine tools, can solve the problems of high investment cost, small size of ball nuts, and narrow application range, etc., and achieve the effects of simplifying machine tool structure, convenient operation and measurement, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

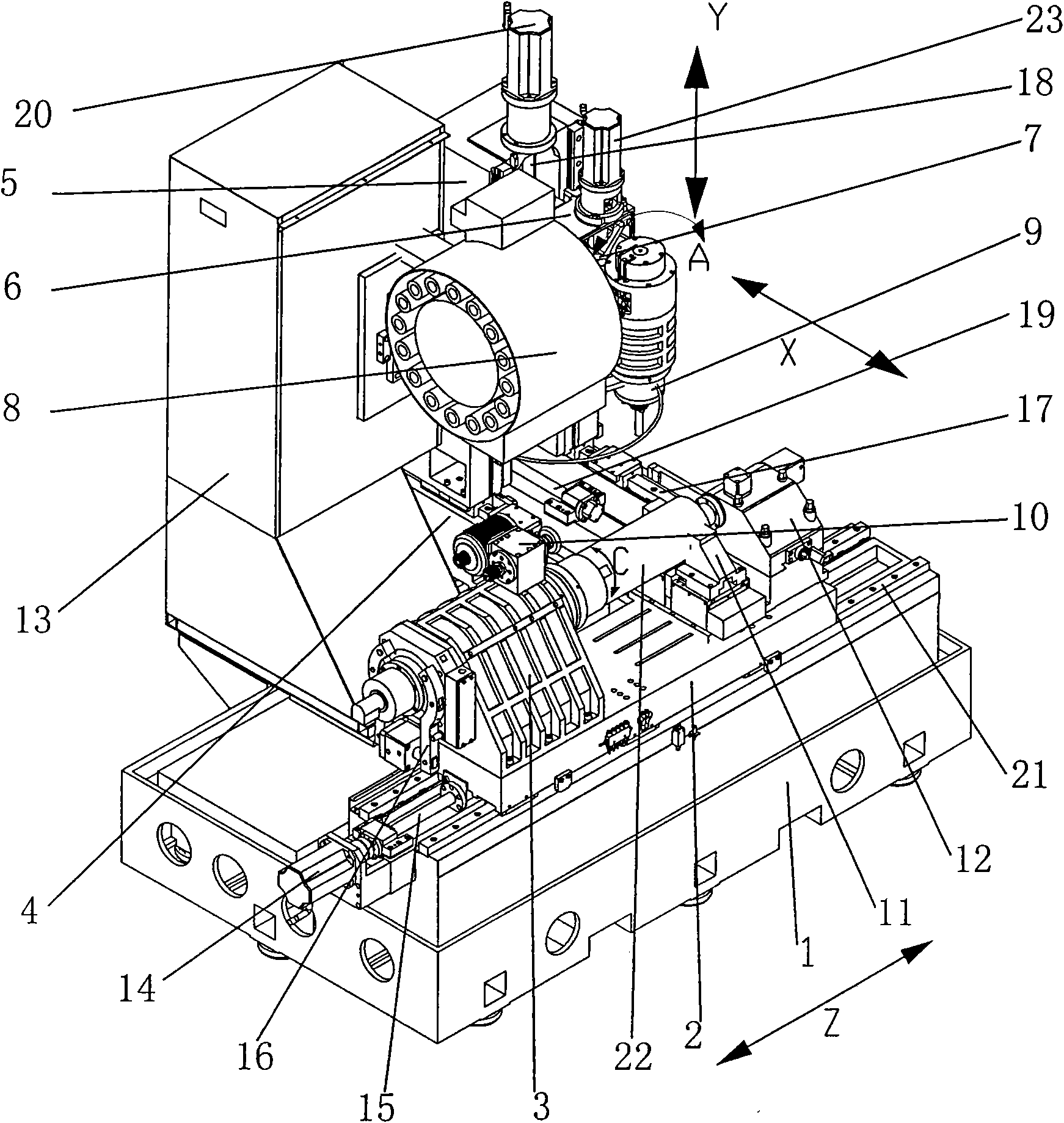

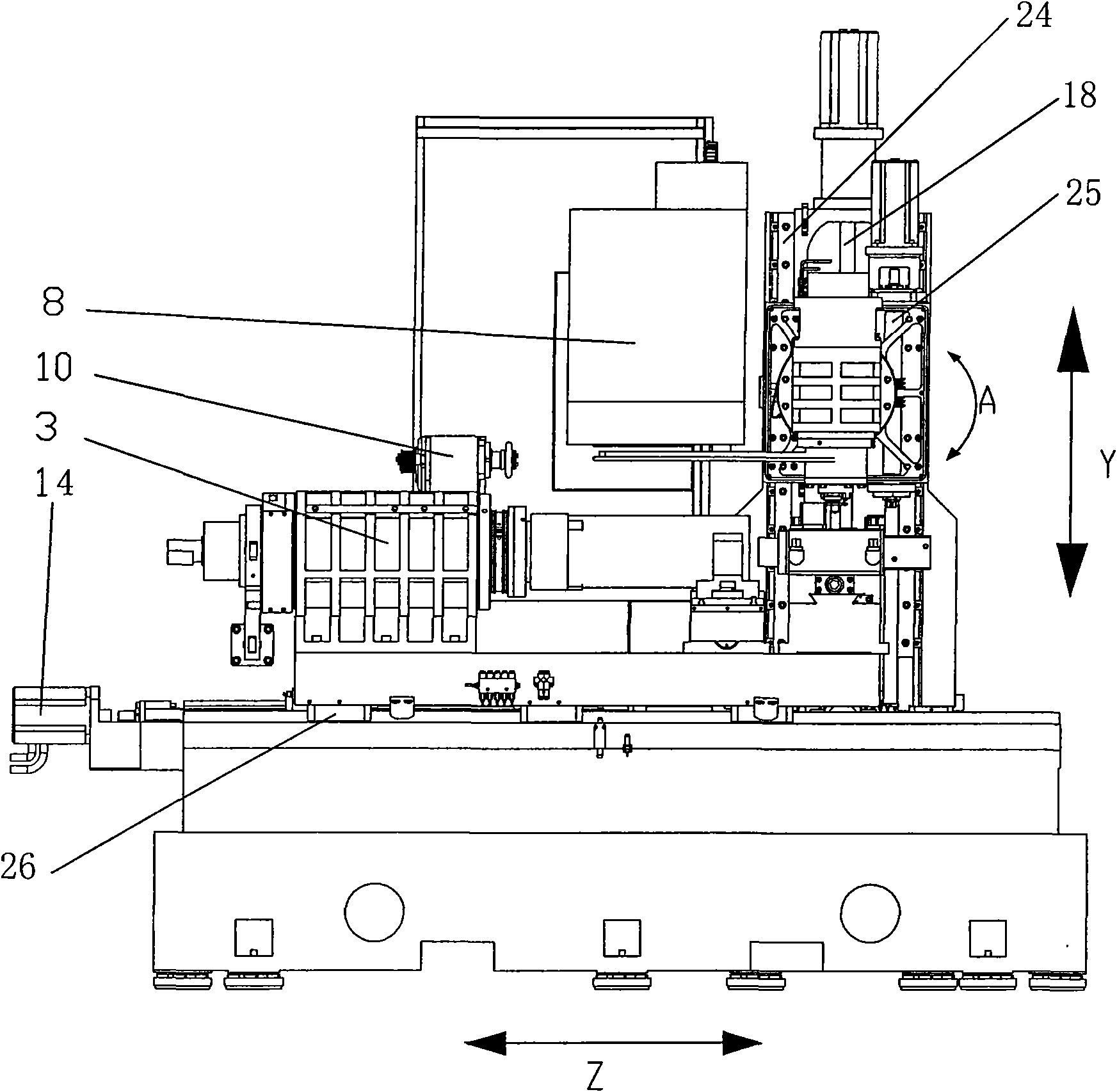

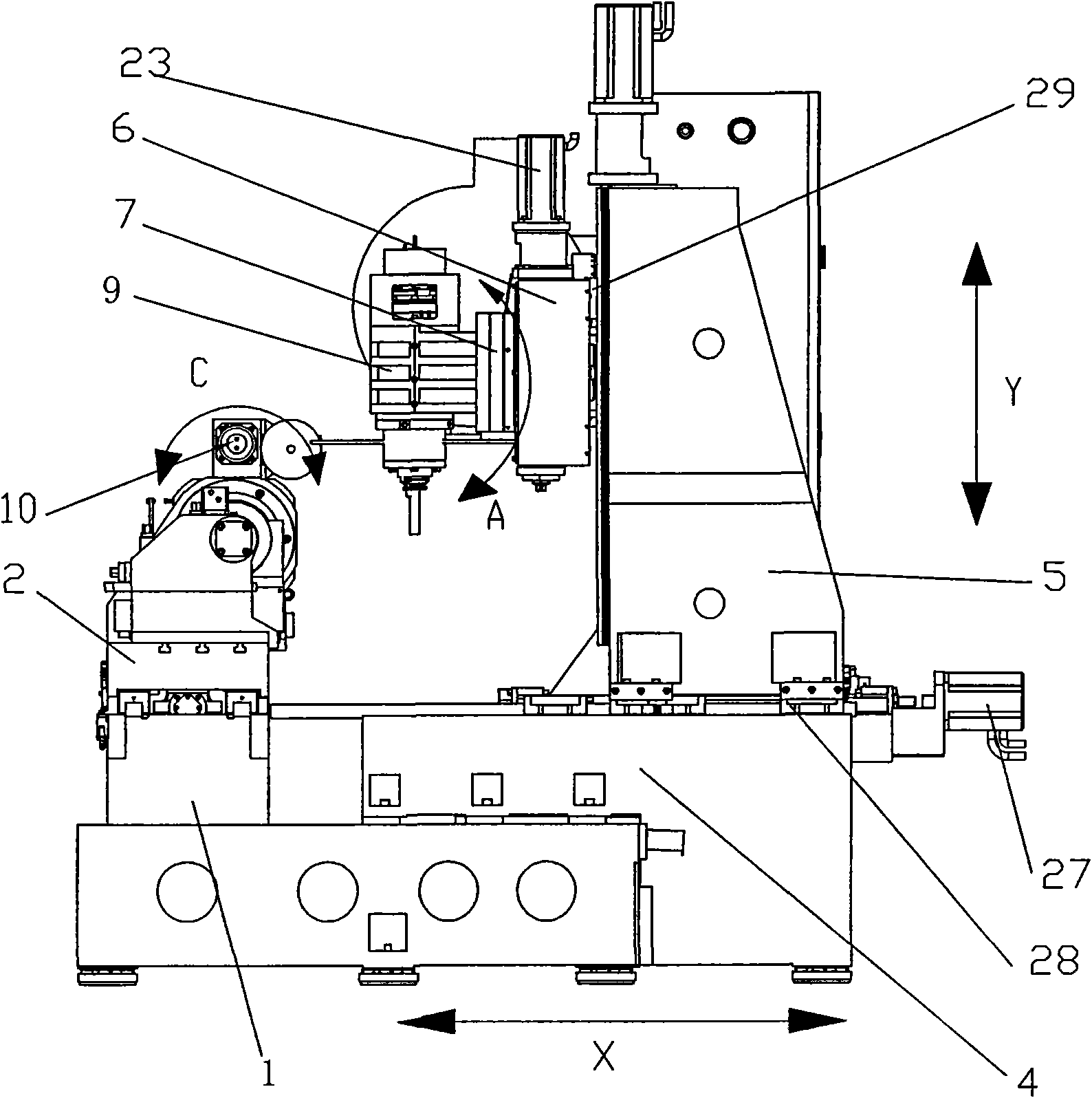

[0033] The present invention will be further described below in conjunction with accompanying drawing.

[0034] In the figure: 1. Bed, 2. Z-direction slide, 3. Workpiece motorized spindle, 4. X-direction bottom plate, 5. Column, 6. Y-direction slide, 7. A-axis rotary table, 8. Grinding wheel magazine, 9 , Grinding electric spindle, 10, Grinding wheel corrector, 11, Steady frame, 12, Tailstock, 13, Grinding tool magazine bracket, 14, Z-axis servo motor, 15, Z-direction ball screw, 16, Work spindle lock Tightening device, 17, X guide rail 18, Y direction ball screw, 19, X direction ball screw, 20, Y direction servo motor, 21, Z guide rail, 22, workpiece, 23, A axis servo motor 24, Y Guide rail 25, worm gear pair 26, Z guide rail slider, 27, X direction servo motor, 28, X guide guide slider, 29, Y guide guide slider, 30, A-axis rotary table locking device.

[0035] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4As shown, the spindle moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com