Sewing track error correction method and device based on 3D robot sewing

A robot and sewing technology, applied in the direction of sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problems of increased difficulty in placing curved surfaces in space, product scrapping, affecting speed and sewing position accuracy, etc., so as to avoid sewing inconsistencies or even scrapping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

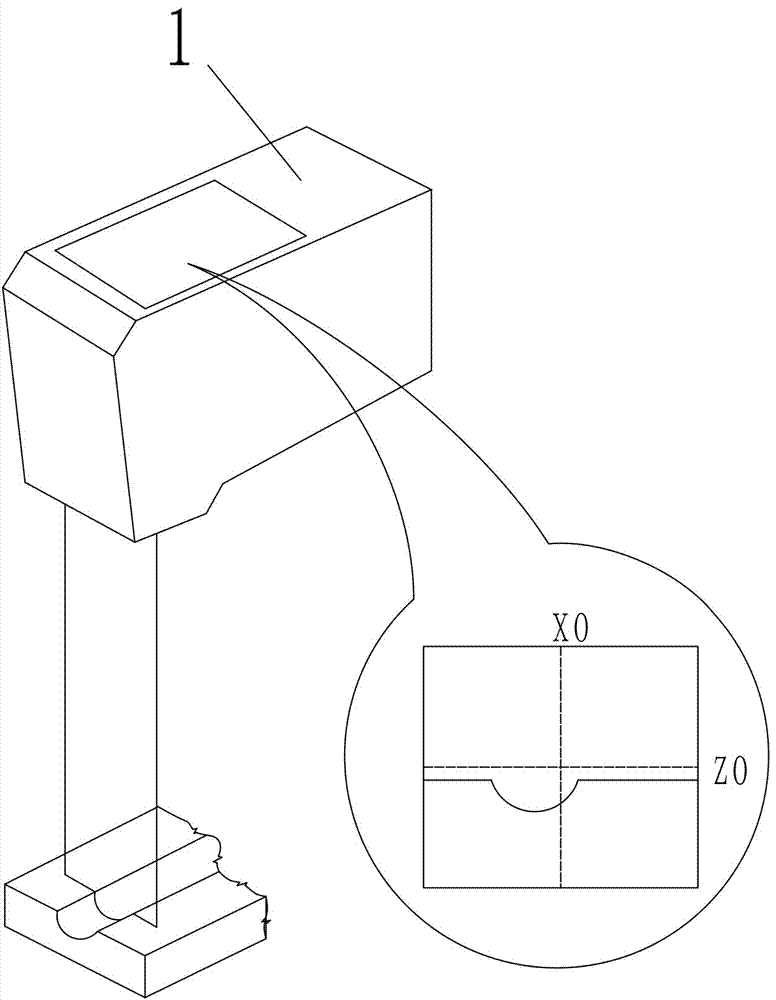

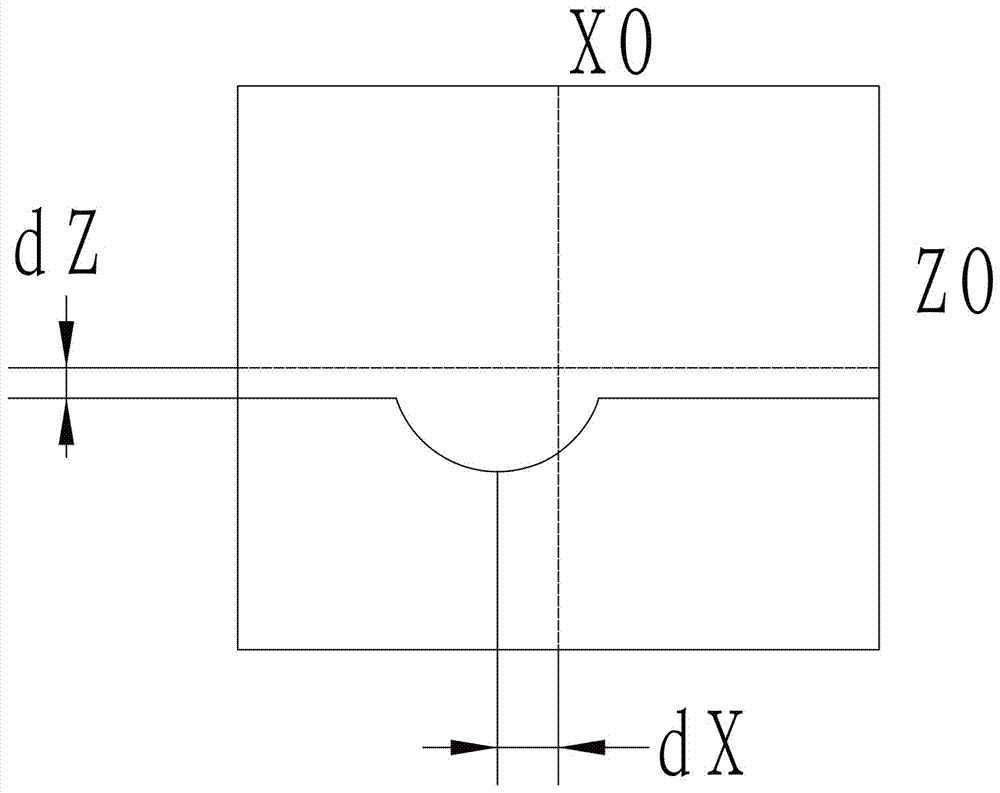

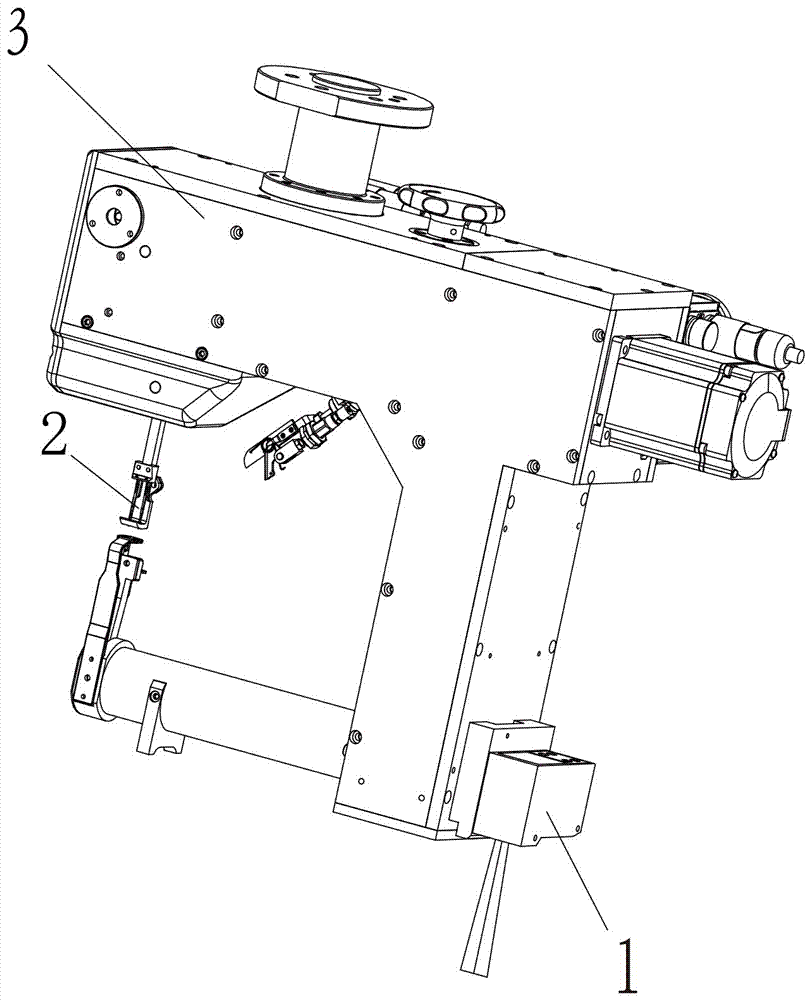

[0021] See attached picture. This embodiment includes a laser line scanner 1, a sewing machine head 3, a mechanical arm 4 and a workpiece 7 to be sewn; the laser line scanner 1 is installed on the sewing machine head 3; the sewing machine head is connected to the mechanical arm through a mounting flange 4 above; controlled by the mechanical arm 4, the whole moves to the set position to start scanning or sewing; the sewing machine head 3 calibrates the intersection point of the sewing machine needle 2 and the needle plate as the sewing tool coordinate system 5 (hereinafter referred to as sewing TCP); A laser line scanner 1 is installed on the sewing machine head 3, which can obtain the data information of the scanning section, and obtain the target tracking position information according to the section data information; the laser line scanner 1 generally uses 2D scanning, that is, depth and lateral offset information As well as the data that can be used for contour surface calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com