All-welded ultra thin-walled storage tank and welding structure suitable for all welding

A welding structure and connecting structure technology, applied in the aerospace field, can solve problems such as no solution proposed, and achieve the effects of improving weld quality and shape and position accuracy, enhancing rigidity, and simplifying welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Structure

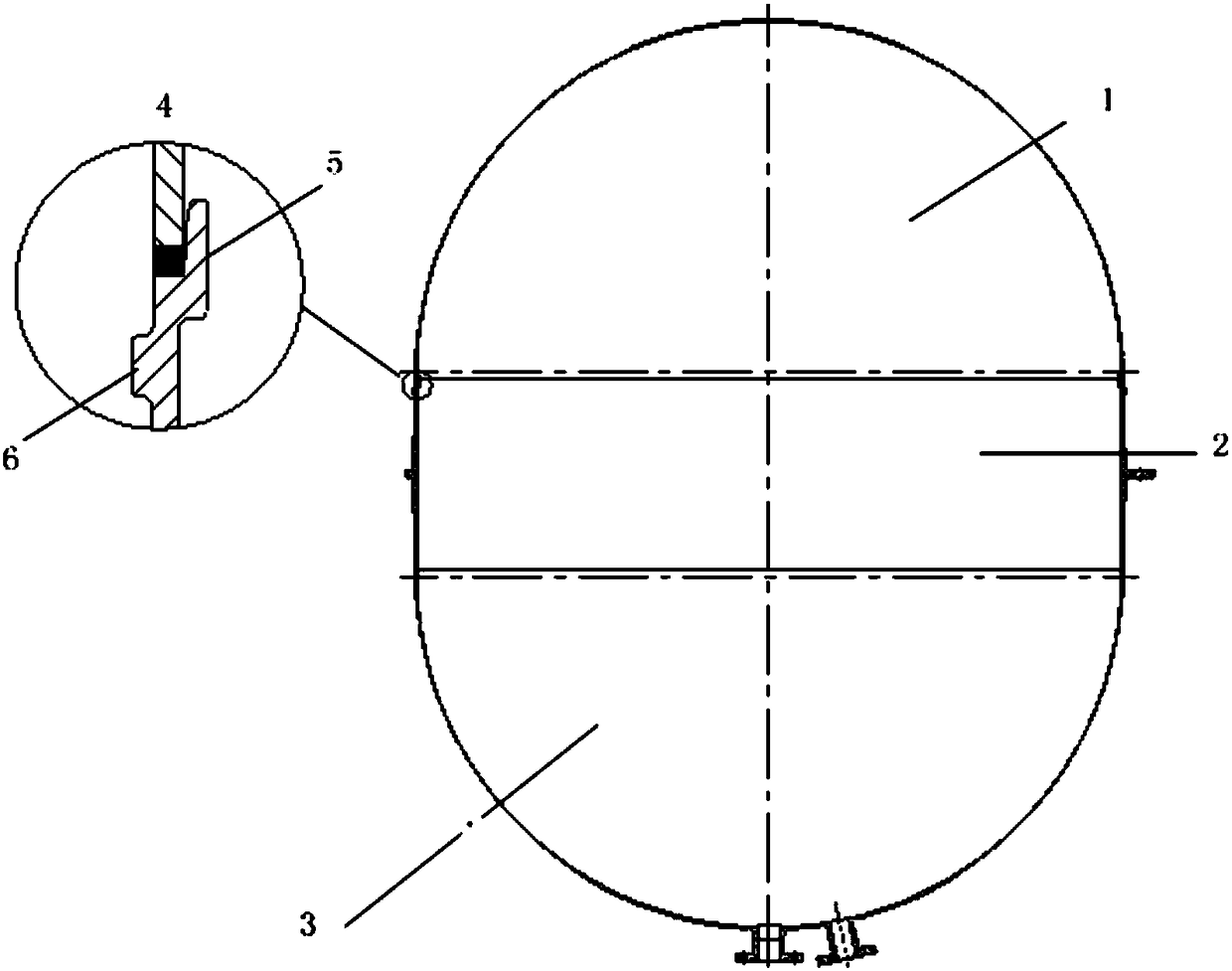

[0050] Such as figure 1 As shown, the storage tank provided in this embodiment includes a front bottom 1, a barrel section 2, and a rear bottom 3, which are fully welded and sealed. figure 1Considering the simplicity of the process, the storage tank shown is the butt weld of the front bottom 1 and the barrel section 2 as the sealing welding, and the bottom locking welding structure 4 is located at the butt weld of the front bottom 1 and the barrel section 2.

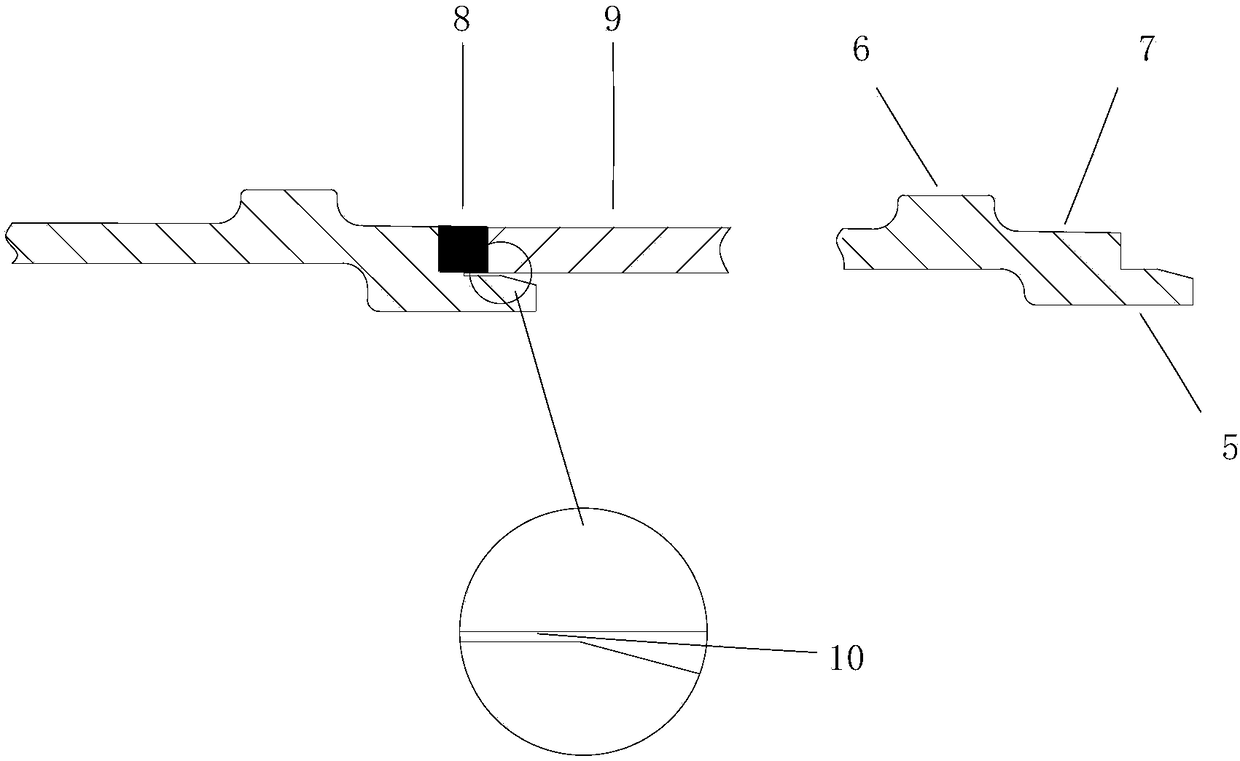

[0051] Different from the existing model with a bottom lock structure with a welding leak that is suitable for fusion welding, this embodiment adopts the characteristics of electron beam welding for ultra-thin wall storage tanks, and designs such as figure 2 Bottom lock welded construction shown.

[0052] The bottom lock welding structure 4 includes a lock bottom 5, a reinforcing boss 6 and an intermediate connecting structure 7; wherein, the locking bottom 5 and the reinforcing boss 6 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com