Elliptical porcelain insulator shape processing device and processing method thereof

A shape processing and insulator technology, which is applied to an oval porcelain insulator shape processing device and its processing field, can solve the problems of reducing product processing quality, affecting processing accuracy, affecting processing efficiency, etc., to avoid uneven changes and improve product qualification. efficiency, and the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

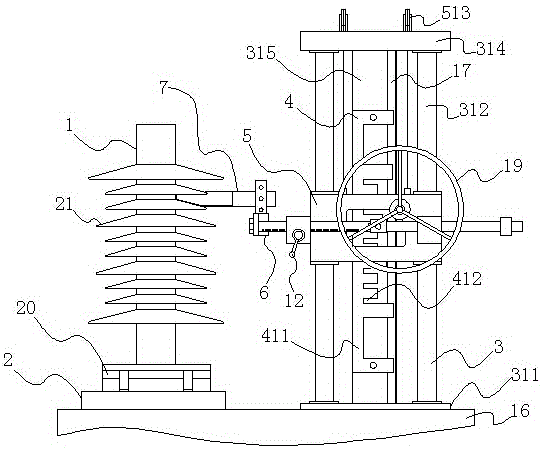

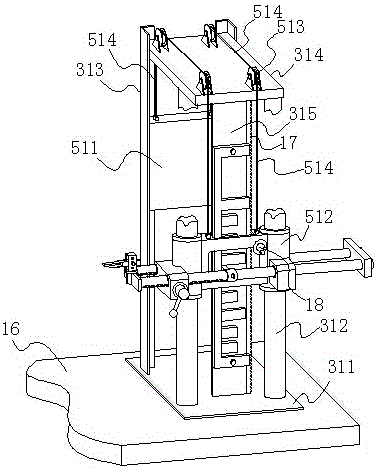

[0065] Embodiment 1: as figure 1 As shown, an elliptical porcelain insulator shape processing device includes a rotating mechanism 2 for placing the insulator mud 1 and driving the insulator mud 1 to rotate, and is arranged next to the rotating mechanism 2 and is used for processing the insulator mud. A porcelain insulator shape processing mechanism for processing the shape of the blank 1. The porcelain insulator shape processing mechanism includes a frame 3, a positioning plate 4 vertically arranged on the frame 3, and can be positioned along the frame 3, The lifting device 5 that moves down and the telescopic device 6 that is arranged on the lifting device 5 and can move horizontally back and forth along the lifting device 5; a positioning groove is arranged on one side of the positioning plate 4, and the telescopic device 6 A trimming knife 7 is provided on one end of the telescopic device 6, and a positioning rod 8 matched with the positioning groove of the positioning pla...

Embodiment 2

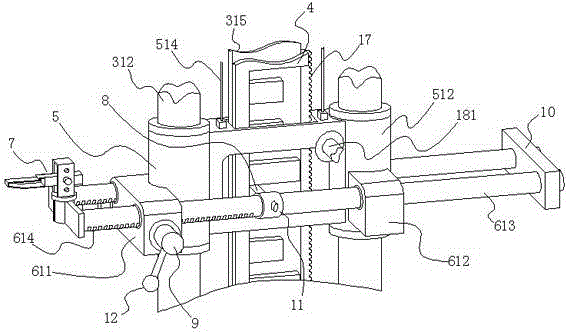

[0095] Embodiment 2: as Figure 7 and Figure 8 As shown, compared with Example 1, the device for processing the shape of an oval porcelain insulator differs in that:

[0096]In this embodiment, the insulator mud is processed by the rotation of the insulator mud, and the repairing knife performs multiple reciprocating movements in the horizontal direction according to the elliptical trajectory to process the insulator mud. In this embodiment, the rotating mechanism 2 can adopt a general rotating table, which can drive the insulator mud 1 to perform autorotation. A pressing plate device 22 is also arranged beside the rotating mechanism 2, and the pressing plate device 22 includes a support rod 221, a connecting rod 222 and a pressing plate 223 arranged beside the rotating mechanism 2; one end of the connecting rod 222 can be detached The other end of the connecting rod 222 is rotatably connected to one side of the pressing plate 223, and the other side of the pressing plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com