A heat source assisted friction stir additive manufacturing device and method

An additive manufacturing and friction stir technology, which is applied in the field of friction stir welding, can solve the problems of difficulty in ensuring that the additive layer is closely combined, powder splashes out of the additive layer, and limited applicability of the additive, so as to improve the utilization rate of materials, improve the Additive efficiency, the effect of improving the overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

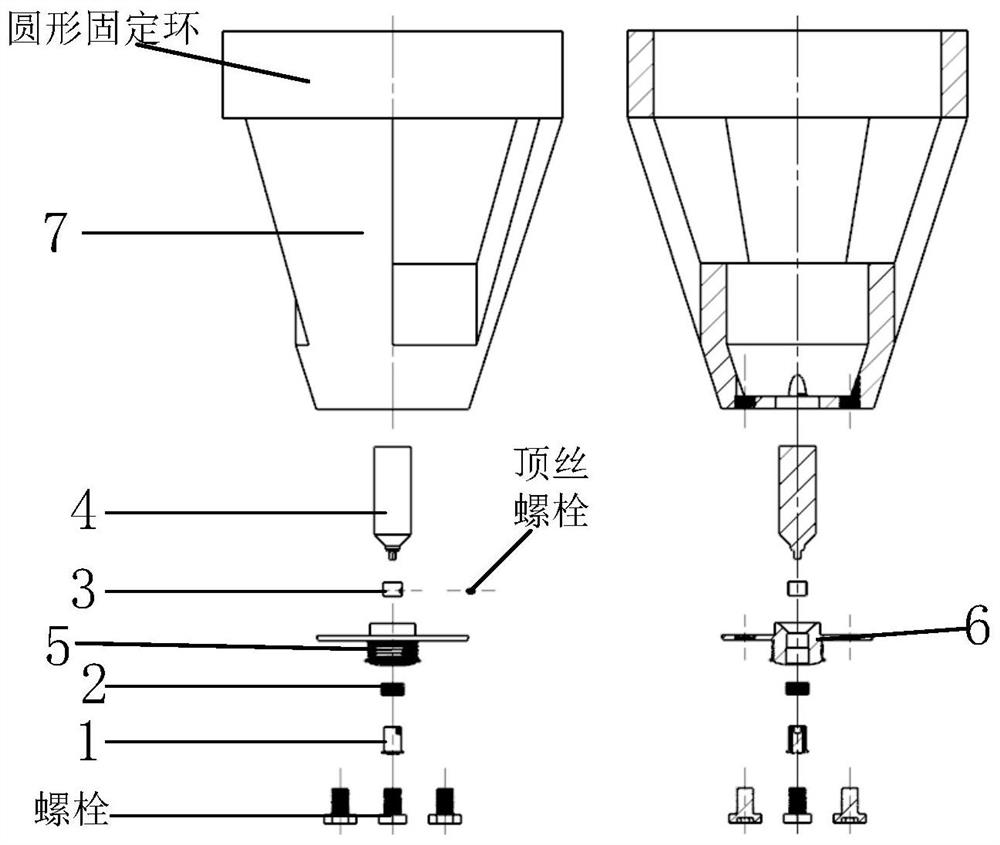

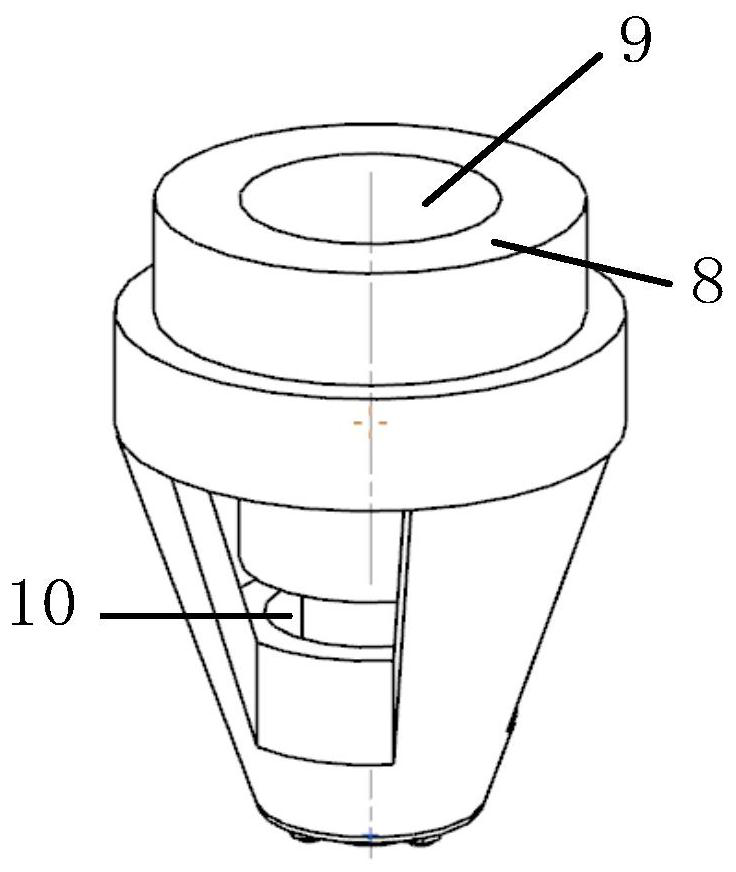

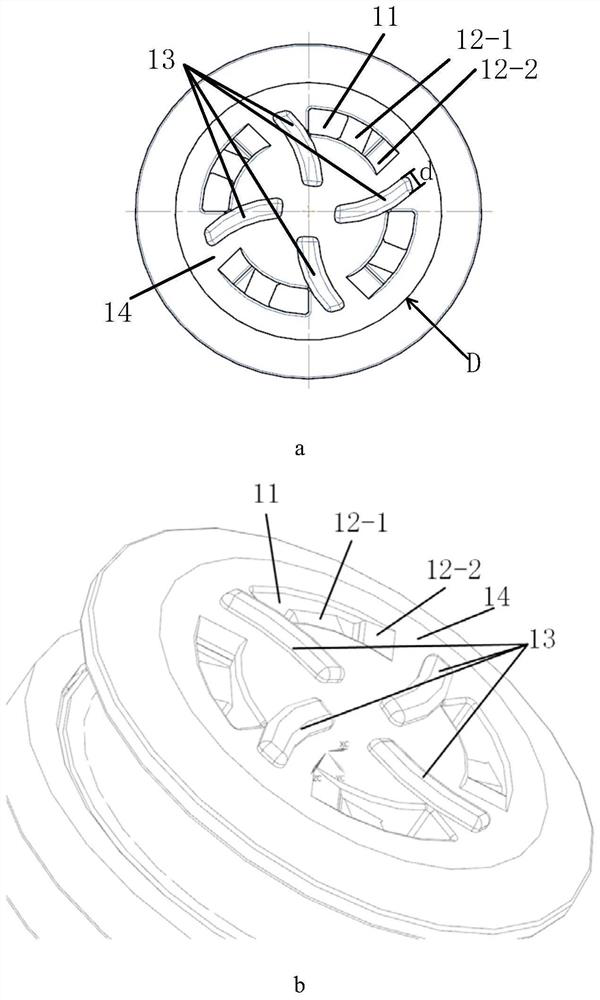

[0034] The technical solution of the present invention is further described with reference to the accompanying drawings: figure 1 , figure 2 , Figure 5 As shown, a heat source-assisted friction stir additive manufacturing device consists of an additive manufacturing stirring head, an eddy current heating device and a powder feeding system. Depend on image 3 , Figure 4 It can be seen that the additive manufacturing stirring head is composed of a stirring head 1 and a clamping device 4, wherein the stirring head 1 is composed of a rolling slope 12, a shaft shoulder 14, and a stirring needle 13; The powder conveying system consists of a powder storage tank 10, a powder conveying positioning ring 3, and a powder conveying channel 11.

[0035] During assembly, the bearing 2 is assembled on the outside of the stirring head 1. The stirring head 1 is composed of a rolling slope 12, a shaft shoulder 14 and a stirring needle 13; the diameter D of the shaft shoulder 14 is 10 mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com