A manufacturing method and device for friction stir near net shape additive of composite materials

A friction stir, near-net-shape technology, used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of high clamping requirements, long processing time, complicated disassembly and assembly, etc., to achieve high material utilization, increase growth rate. Material efficiency and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

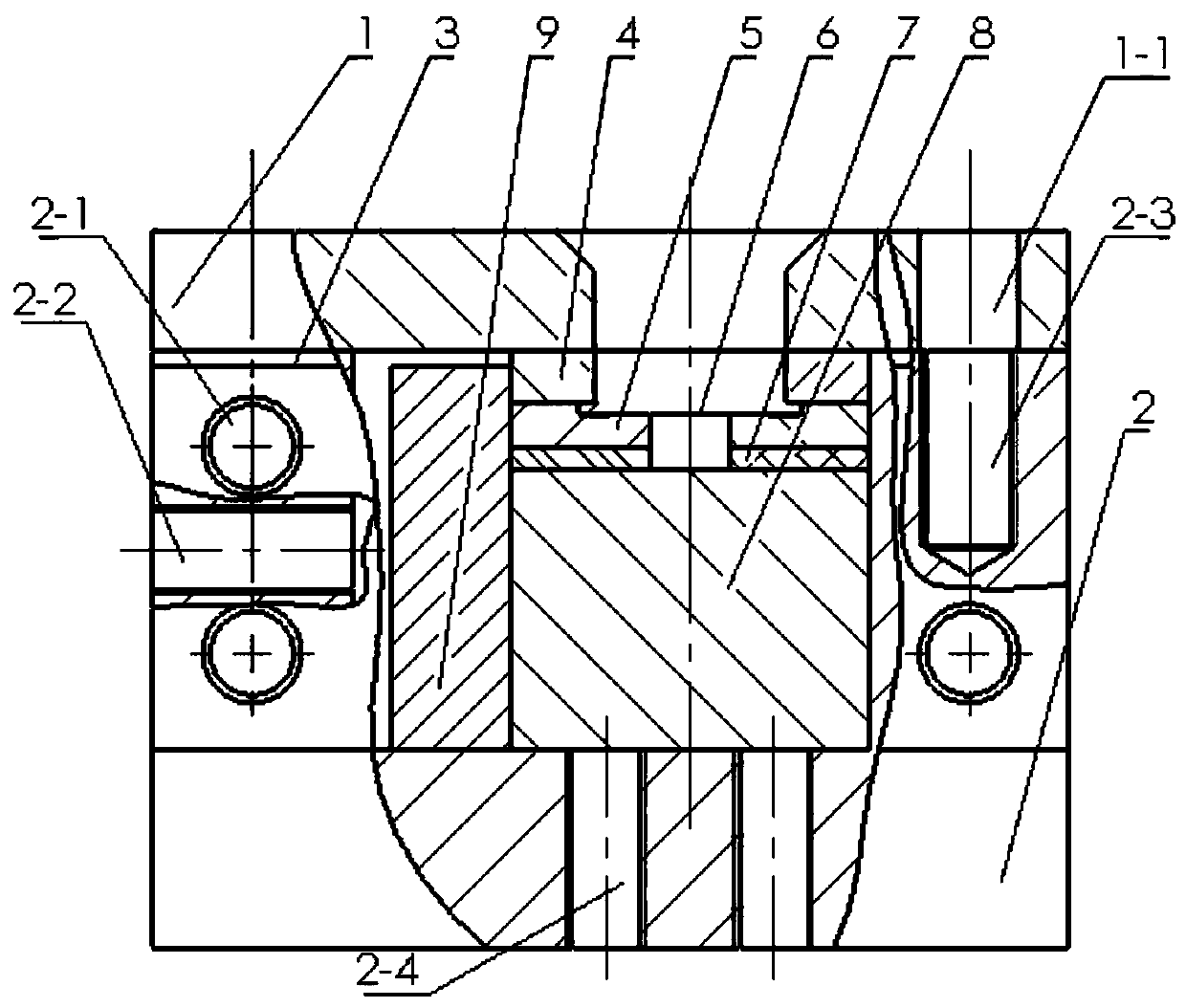

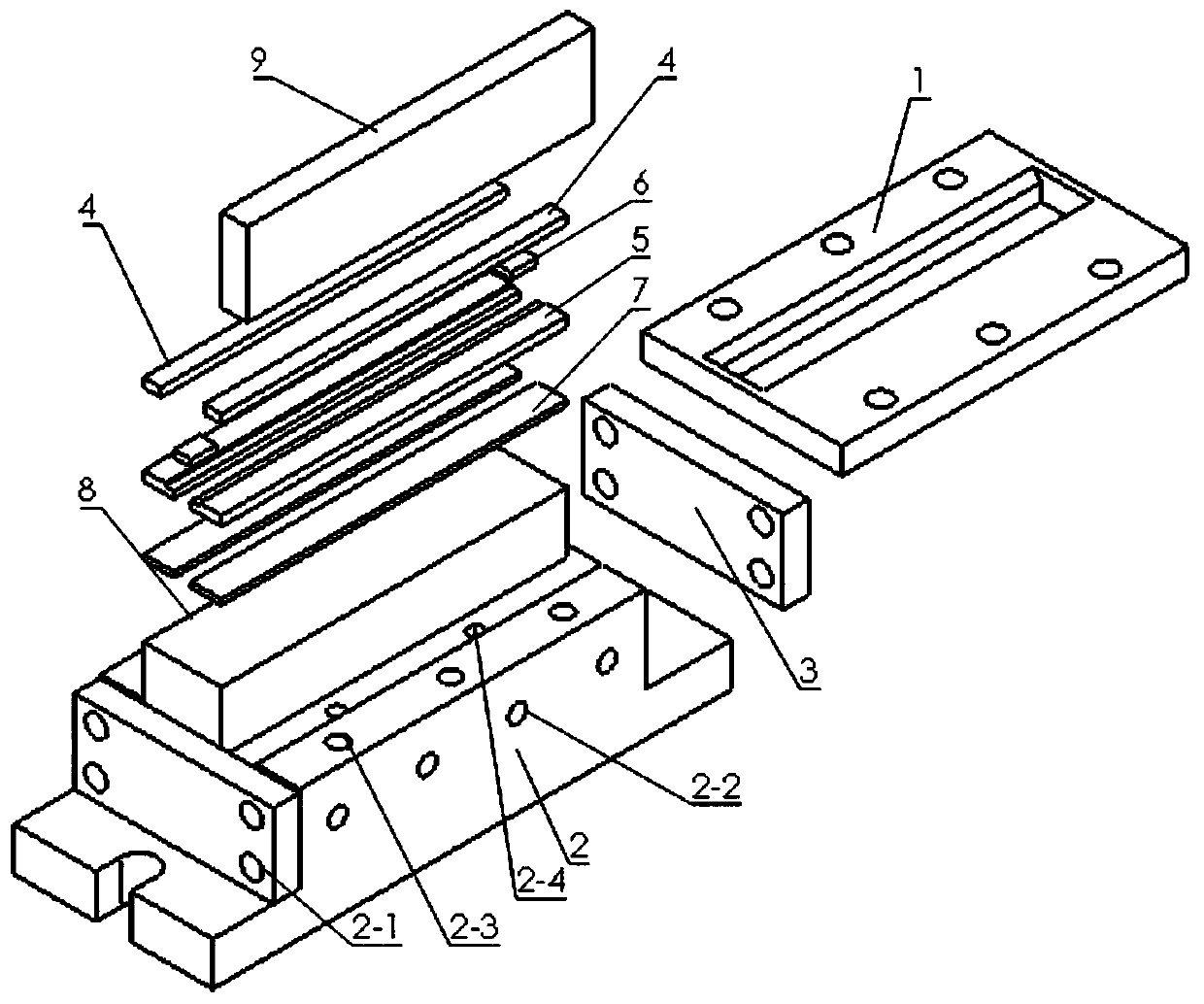

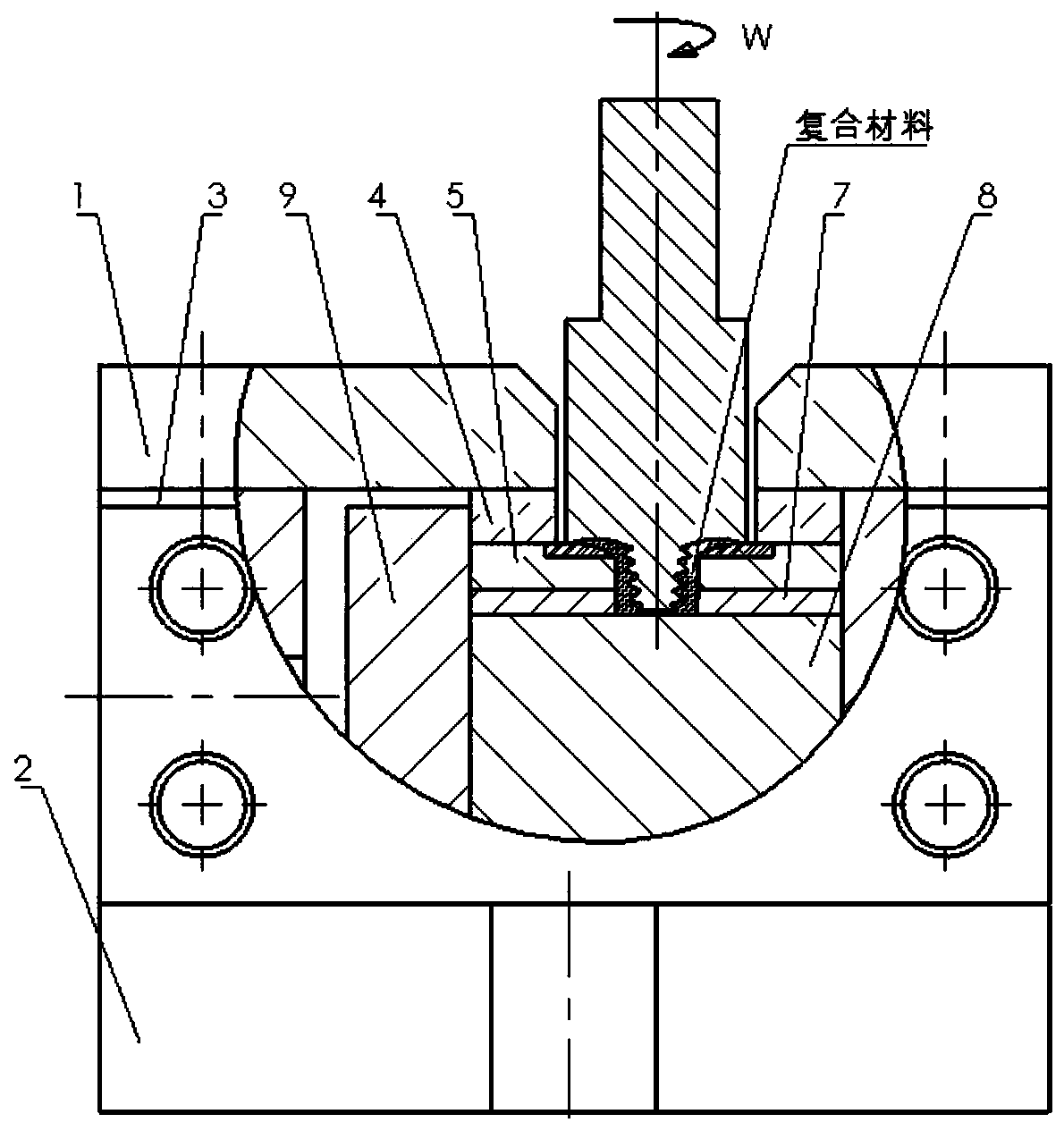

[0032] Such as Figure 1-3 As shown, this embodiment describes in detail a manufacturing method and device for friction stir near-net shape additive of composite materials according to the present invention.

[0033] Such as figure 1 and 2 As shown, this embodiment provides a device for friction stir near-net shape additive of composite materials, including a mold base 2, a cavity plate and a cover plate 1, and end stops are installed at both ends of the mold base 2 Plate 3, a pad 8 is placed in the cavity of the mold base 2, and the two ends of the pad 8 are against the end baffle 3, and the side of the pad 8 is equipped with a side baffle 9, and the side baffle 9 and the two A terminal baffle can better stabilize the cushion block 8. A cavity plate is arranged on the top of the cushion block 8. The cavity plate is arranged as a left and right split and a rectangular gap is reserved in the middle. The cover plate 1 is connected to the upper part of the mold base 2. There i...

Embodiment 2

[0045] Embodiment 2, in step 2, the width of the plug 6 is 9mm ± 0.01, the material thickness is 4mm, the rotation speed is 600rpm, the welding speed is 45mm / min, the inclination angle of the stirring head is 2°, and the stirring needle is stirred at least 5 times; other steps and embodiments same.

Embodiment 3

[0046] Embodiment 3, in step 2, the width of the plug 6 is 10.5±0.01mm, the material thickness is 4mm, the rotation speed is 750rpm, the welding speed is 30mm / min, the inclination angle of the stirring head is 2°, and the stirring needle is stirred at least 5 times; other steps and implementation Example is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com