Biogas tea fixing machine

A greening machine and tea technology, which is applied in the field of greening machines, can solve the problems of high cost of greening tea and reduce the cost of greening tea, so as to improve the efficiency of greening work, reduce the time of greening, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

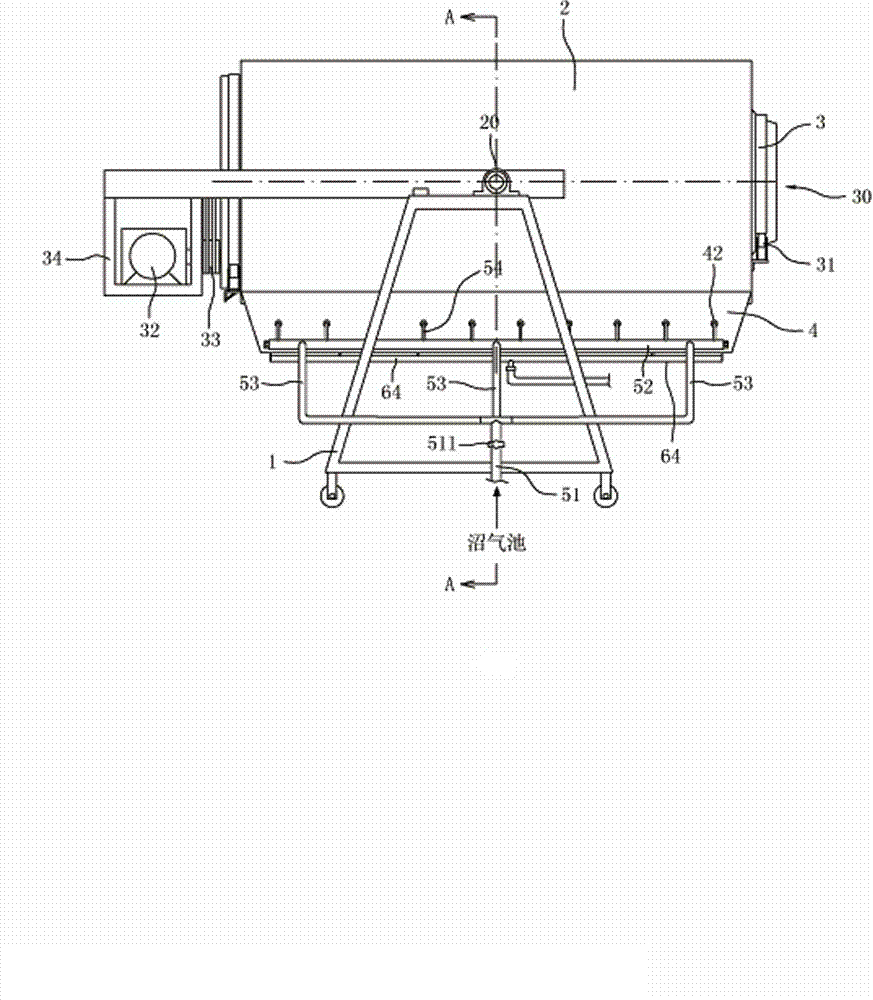

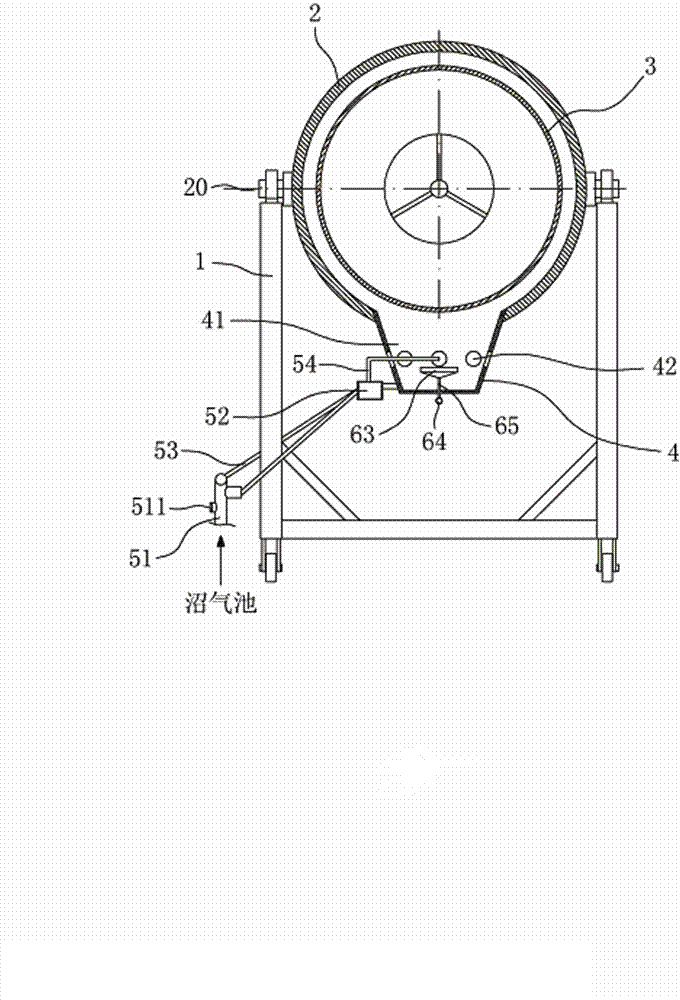

[0026] refer to Figure 1 to Figure 4 . The biogas tea degreening machine comprises a frame 1, a horizontal heat-insulating outer cylinder 2, a tea degreening drum 3, a driving device for the tea degreening drum 3, and a heating device. The outer cylinder 2 is made of heat-insulating materials, the middle parts of both sides of the outer cylinder 2 are reversibly supported on the frame 1 through the supporting short shaft 20, and the tea greening roller 3 is rotatably nested in the outer cylinder 2 through the support roller 31 ; The driving device of the tea drying cylinder 3 includes a driving motor 32, and the driving motor 32 drives the tea drying through a transmission mechanism 33. The drum 3 rotates; the rear end of the outer cylinder 2 is connected with a motor bracket 34 , and the drive motor 32 is fixed on the motor bracket 34 . External force is applied to the front end of the outer cylinder 2, and the outer cylinder 2 can be overturned around the supporting short...

Embodiment 2

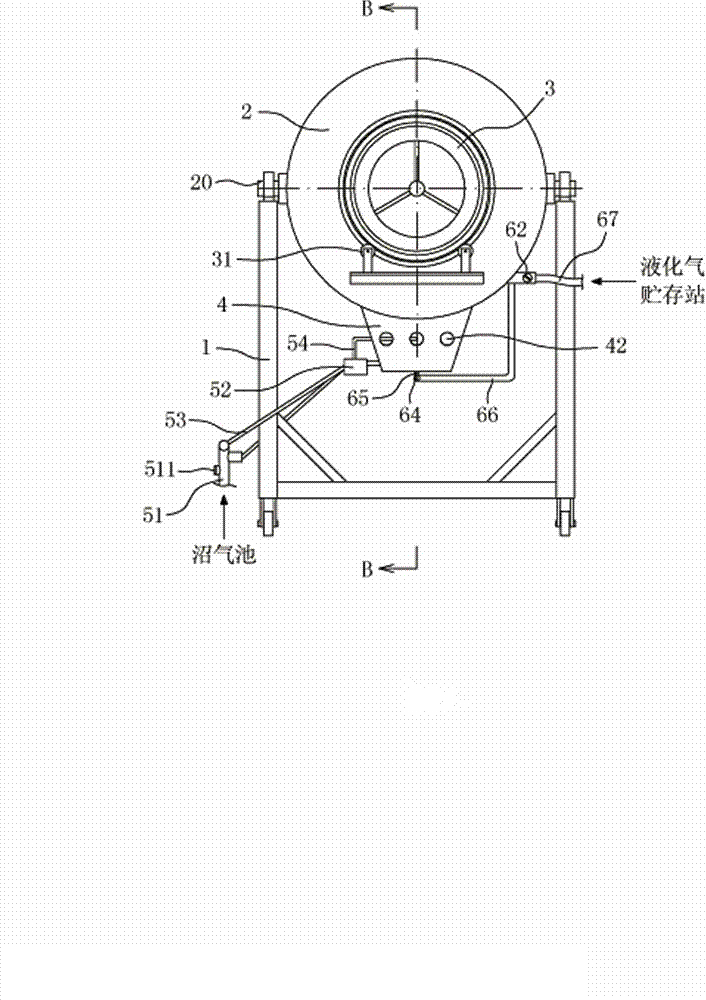

[0033] refer to Figure 5 and refer to Figure 1 to Figure 4 . The difference between this embodiment and Embodiment 1 is that the liquefied gas burning burner 63 in the furnace 41 is an integral burner, and the integral liquefied gas burning burner 63 is fixed on the inner bottom surface of the furnace 41 and is integrally formed with a through hole. Out of the joint on the bottom surface of the stove 4, the joint of the liquefied gas burning burner head 63 is connected to the liquefied gas storage station through the liquefied gas connection branch pipe 66, the ignition switch, and the gas pipeline. Refer to Embodiment 1 for other structures, and details are not repeated here.

[0034]During use, open the liquefied gas storage station to supply gas to the gas pipeline 67, impel the liquefied gas igniter 61 to ignite the liquefied gas burner 63 through the ignition switch 62, then open the valve 511 on the biogas delivery pipeline 51, and pass through the furnace 41 The bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com