centrifugal fan

A centrifugal fan and damper technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as affecting production or use, increasing air supply resistance, and low air supply efficiency, and achieving smooth and reasonable air supply. The effect of large air volume and air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

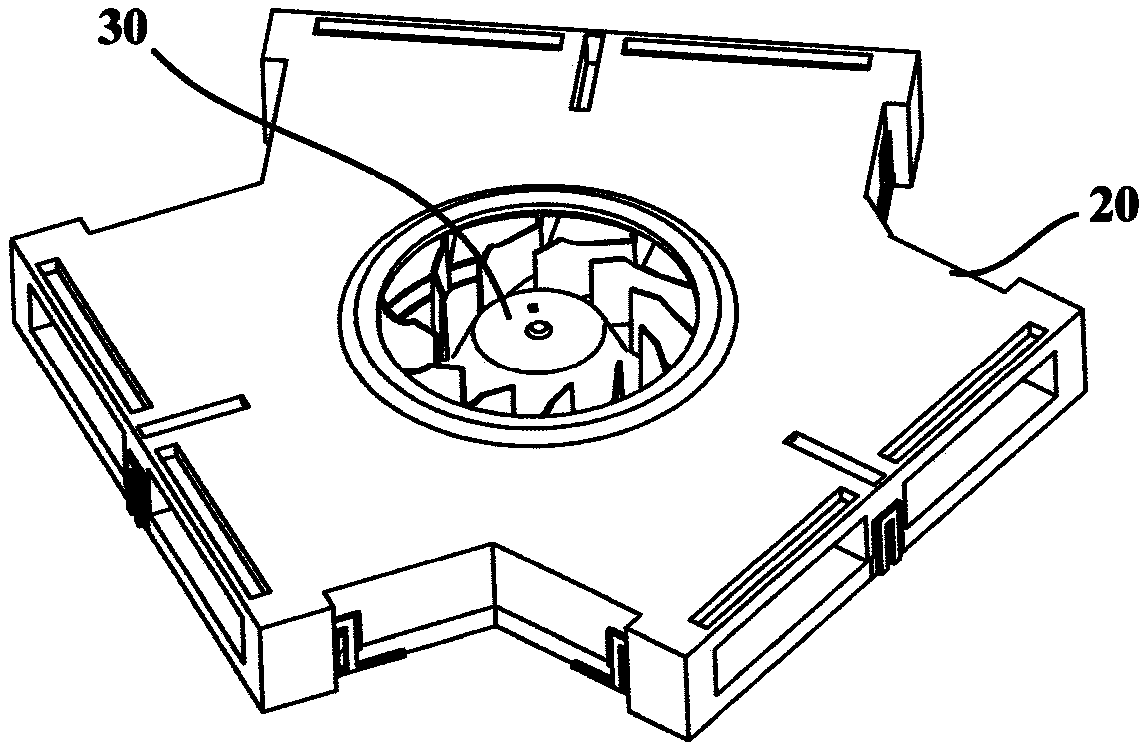

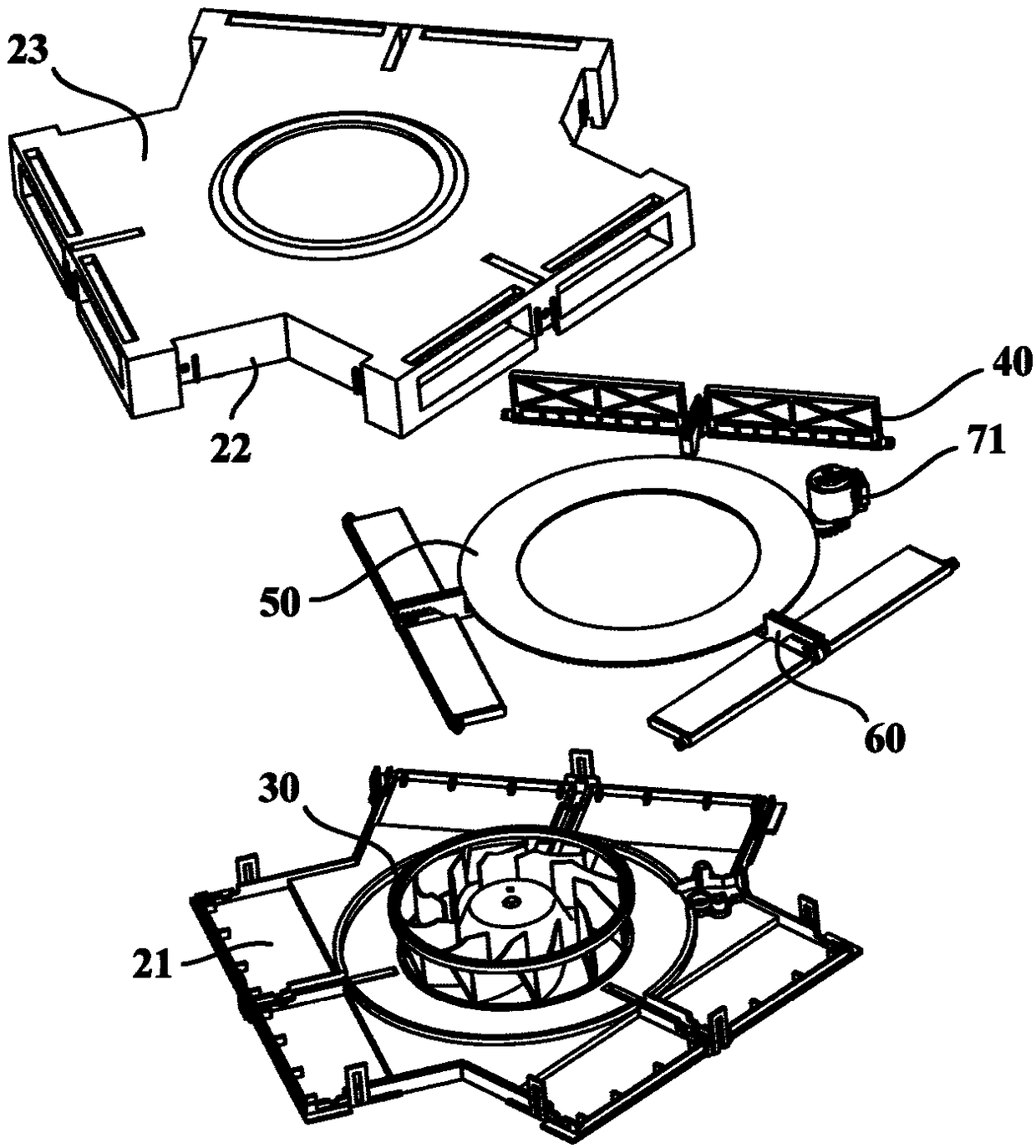

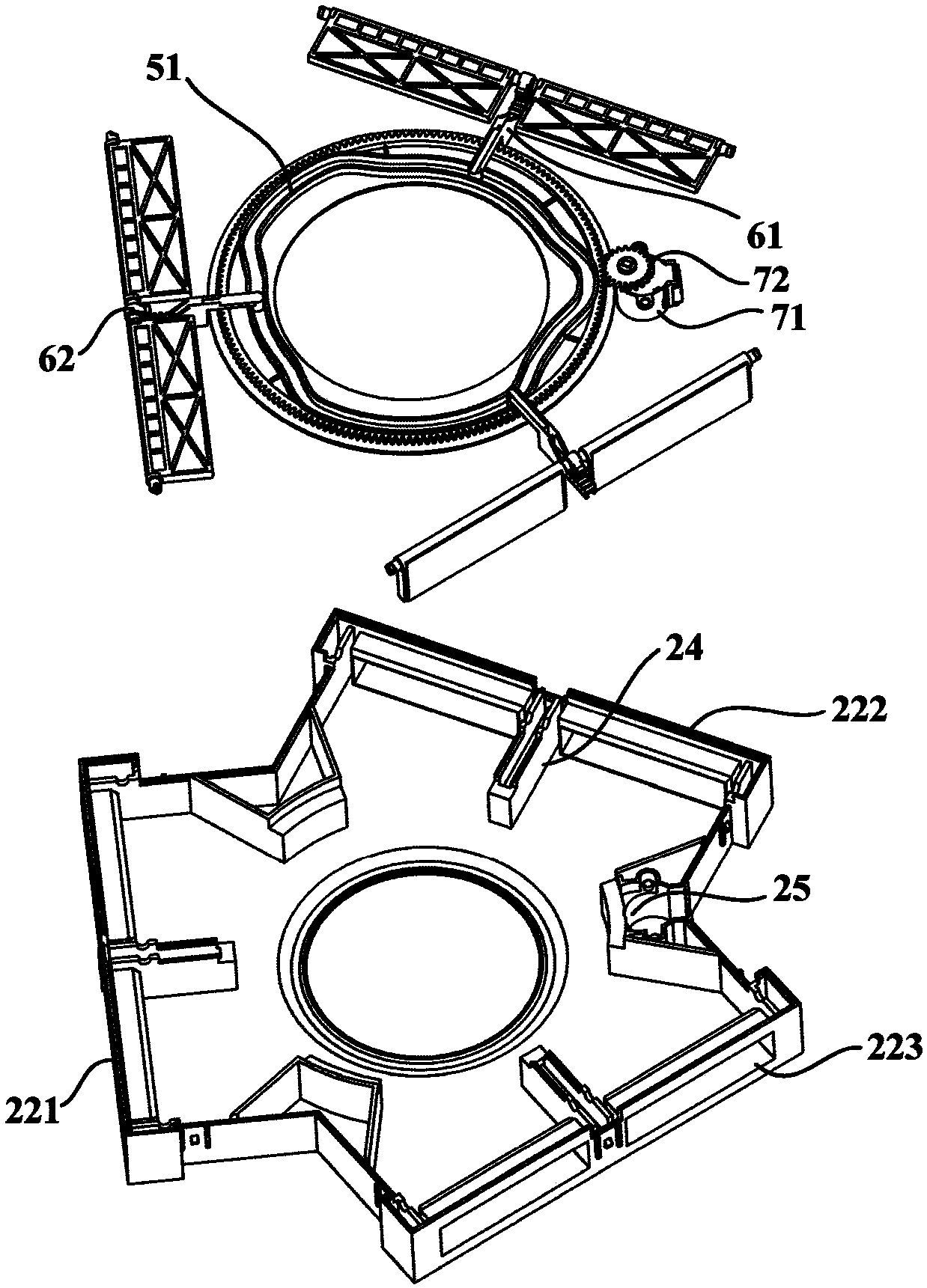

[0040] figure 1 is a schematic structural diagram of a centrifugal fan according to an embodiment of the present invention; figure 2 and image 3 They are respectively a schematic exploded view of a centrifugal fan and a schematic exploded view of a partial structure according to an embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a centrifugal fan. The centrifugal fan may include a casing 20 , a wind wheel 30 , multiple sets of damper flaps 40 , a rotating member 50 and a transmission mechanism 60 .

[0041] The case 20 may have a bottom case part 21 , a peripheral wall part 22 and a cover part 23 . Specifically, the bottom case part 21 may be in the shape of a plate, and the cover part 23 may also be in the shape of a plate. The peripheral wall portion 22 can be integrally formed with the cover portion 23 , that is, the peripheral wall portion 22 extends from the cover portion 23 to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com