centrifugal fan

A centrifugal fan and air intake technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low air supply efficiency, reduced air volume, and increased cost, and achieves reasonable structure layout and large air supply volume. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

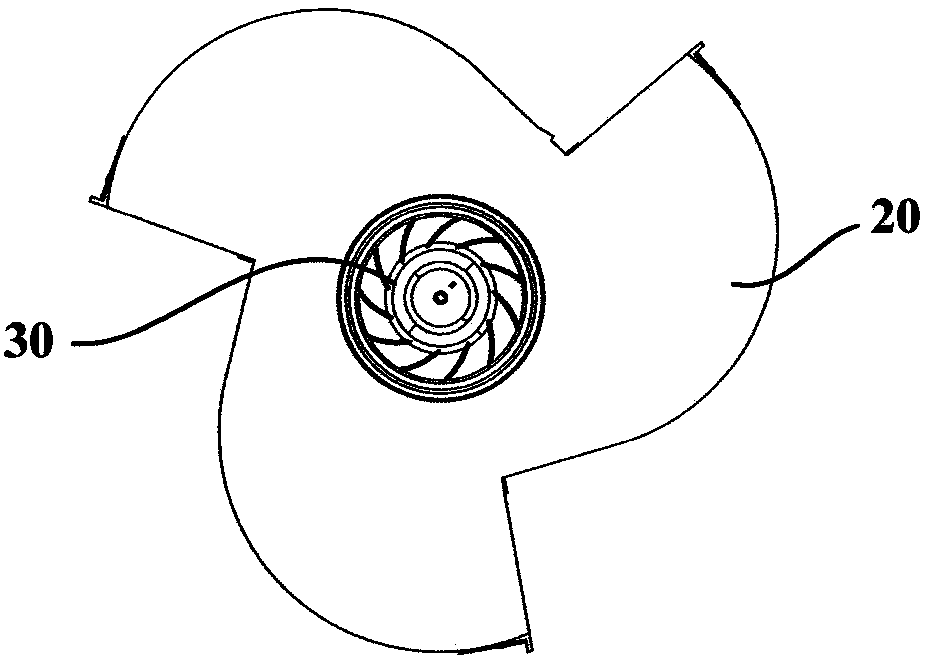

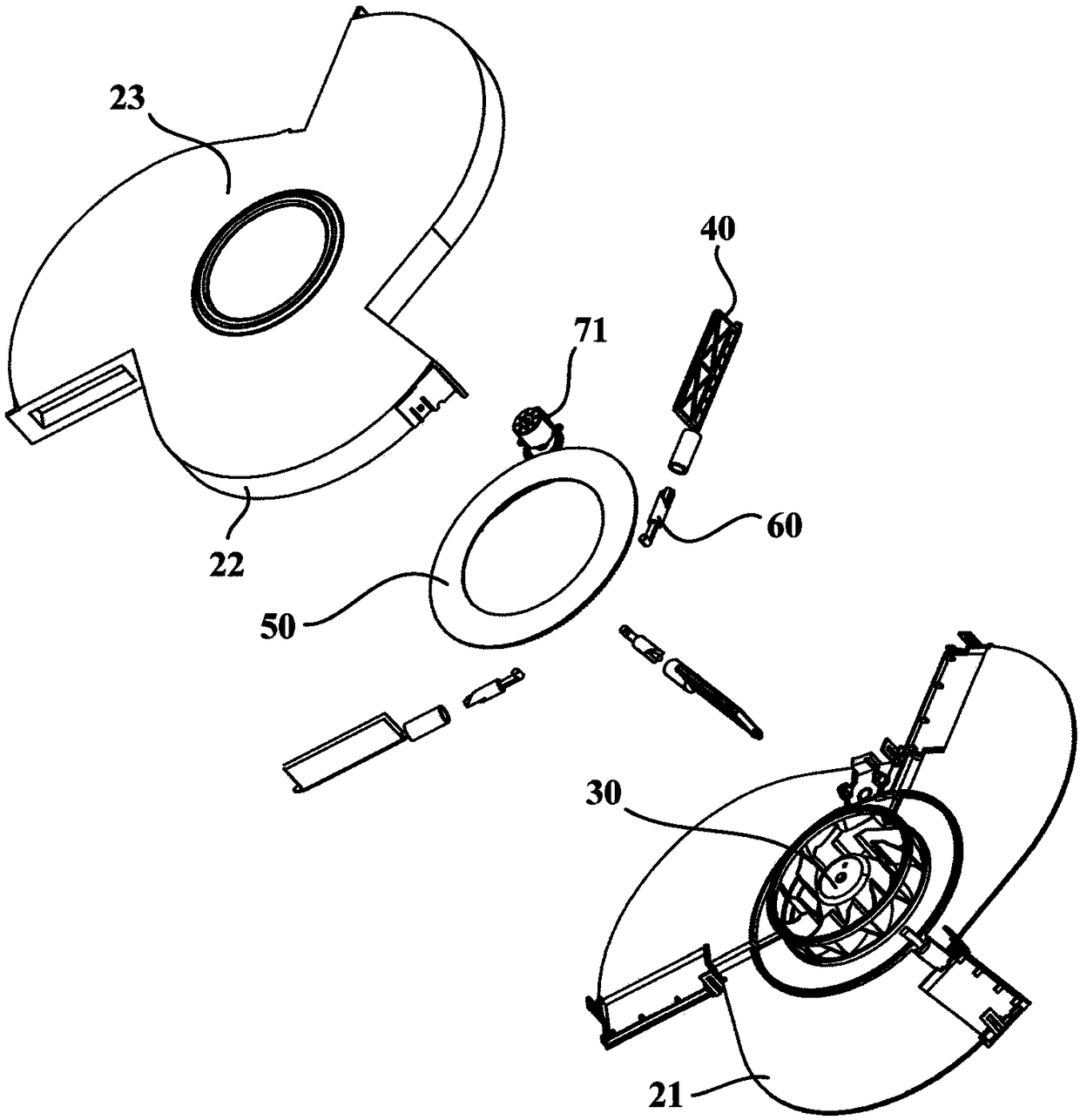

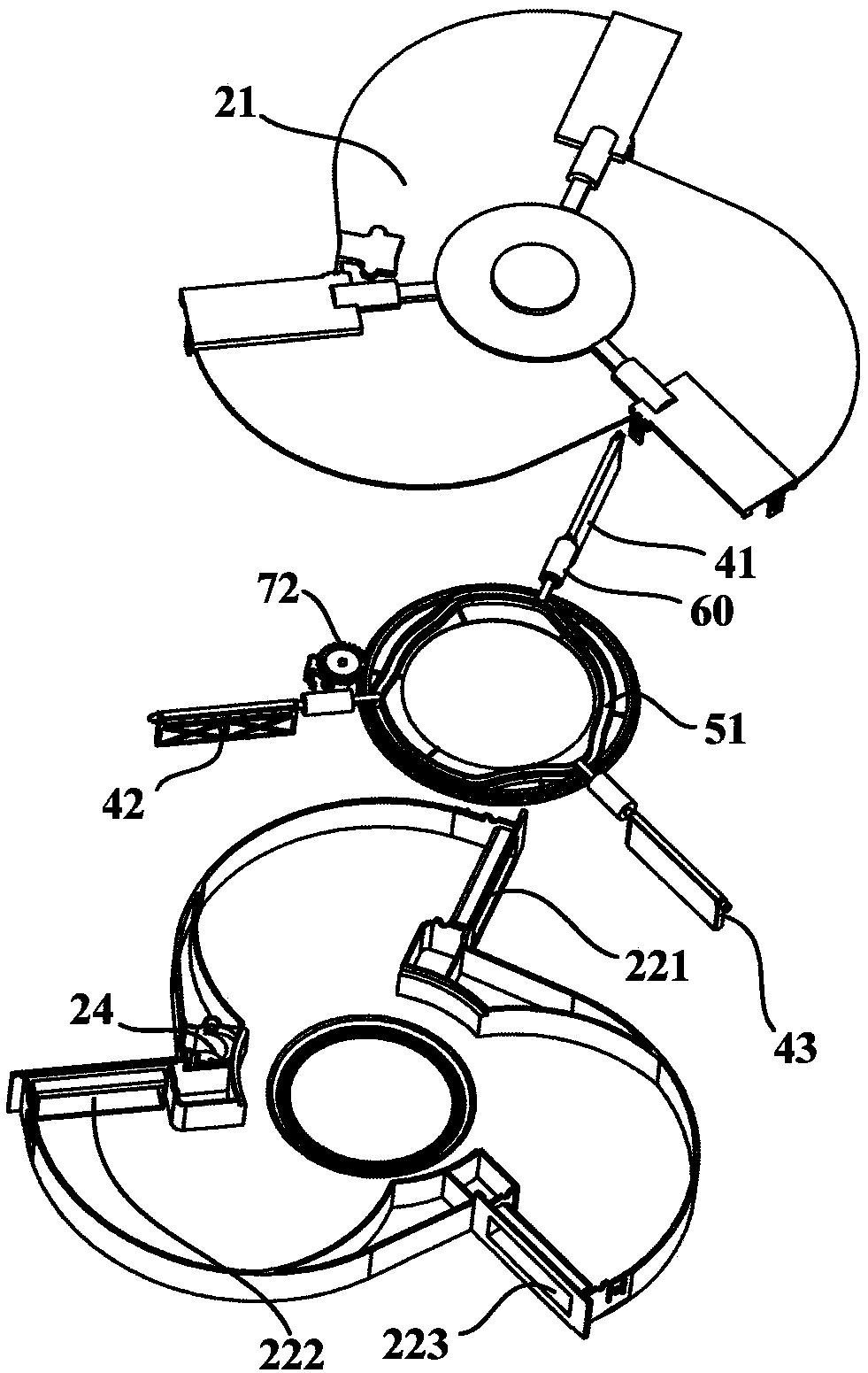

[0041] figure 1 is a schematic structural diagram of a centrifugal fan according to an embodiment of the present invention; figure 2 with image 3 are schematic exploded views of a centrifugal fan according to an embodiment of the present invention; Figure 4 is a schematic partial structural diagram of a centrifugal fan according to an embodiment of the present invention. Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a centrifugal fan. The centrifugal fan may include a casing 20 , a wind wheel 30 , a plurality of flaps 40 , a rotating member 50 and a transmission mechanism 60 .

[0042] The case 20 may have a bottom case part 21 , a peripheral wall part 22 and a cover part 23 . Specifically, the bottom case part 21 may be in the shape of a plate, and the cover part 23 may also be in the shape of a plate. The peripheral wall portion 22 can be integrally formed with the cover portion 23 , that is, the peripheral wall portion 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com