Vehicle air-conditioning related technique having refrigetation cycle of supercritical refrigerant

A vehicle air conditioner and refrigerant technology, which is applied to irreversible cycle compressors, refrigerators, vehicle components, etc., can solve the problems of inability to fully ensure the heat release of refrigerants, difficulty in obtaining heat exchange performance, and poor energy utilization, etc., to achieve Effective use of energy, high cooling performance, and reduced ventilation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In the following paragraphs, some preferred embodiments of the invention will be described by way of illustration and not limitation. It should be understood that many other modifications to these illustrated embodiments can be made by those skilled in the art in light of this disclosure.

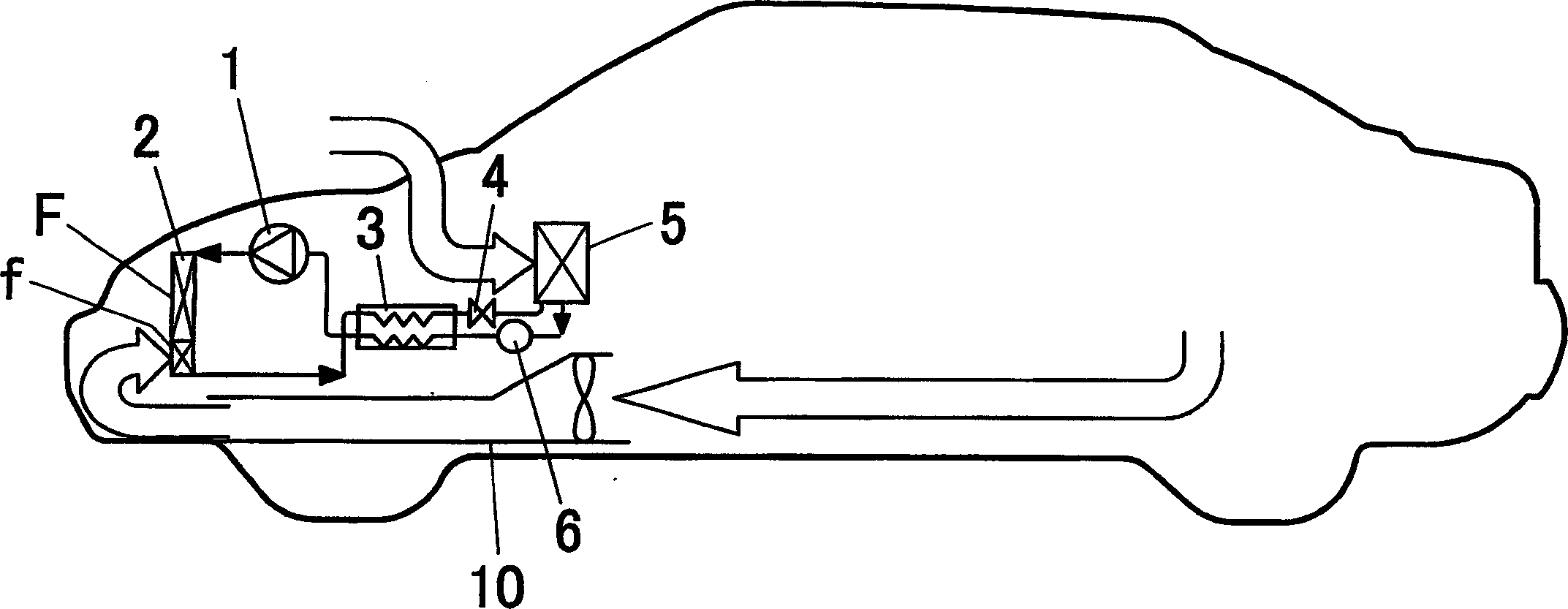

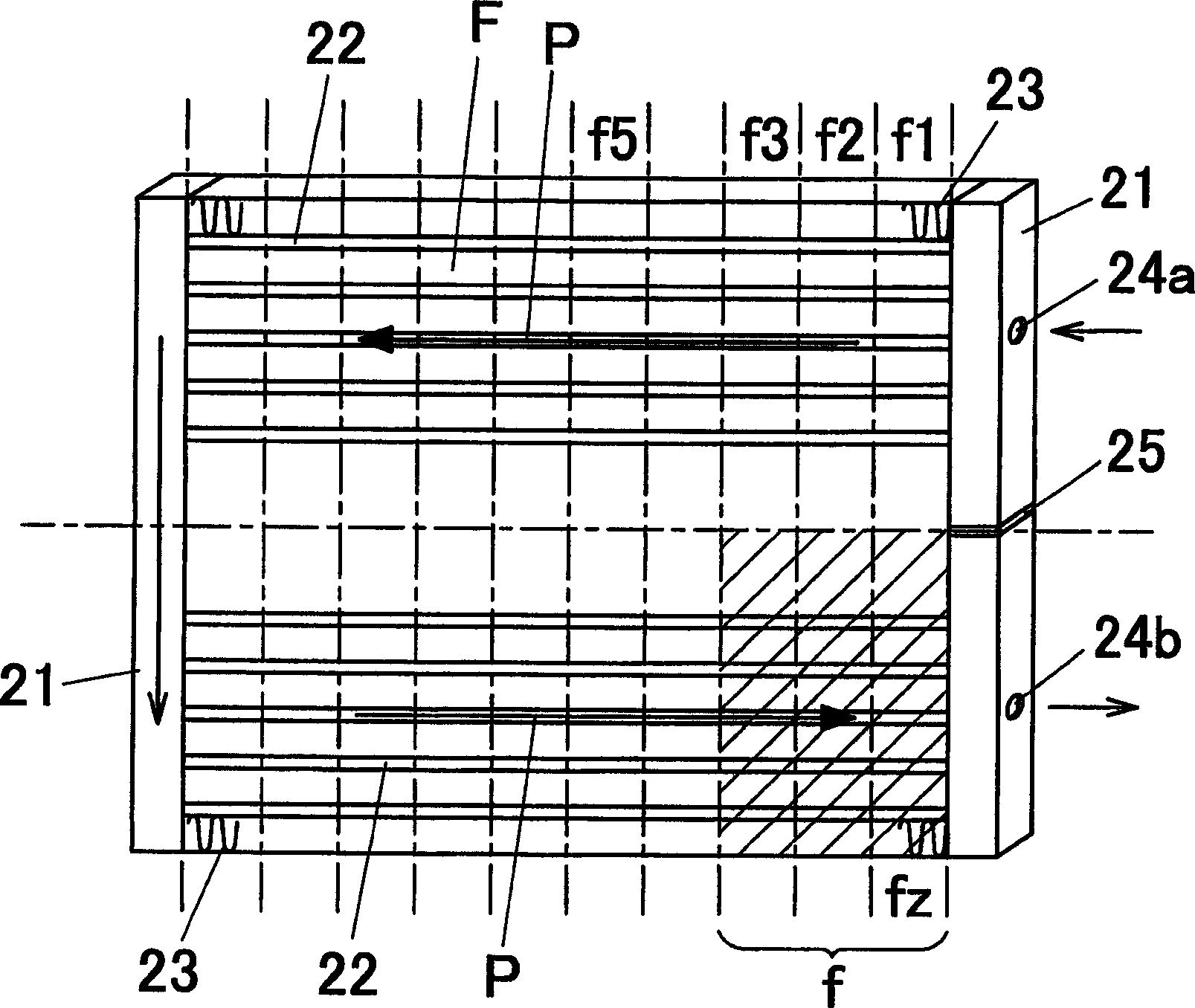

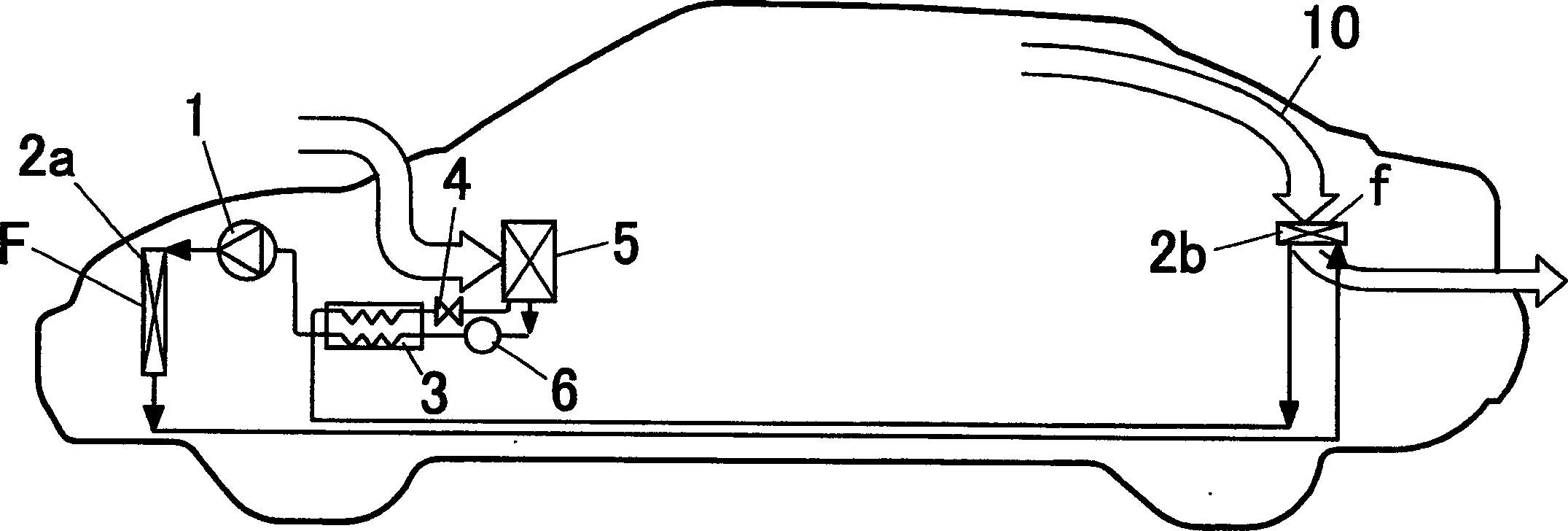

[0099] figure 1 is a schematic configuration diagram showing an automobile air conditioning system using the air conditioning apparatus according to the embodiment of the present invention. The refrigeration cycle used in the car utilizes components such as carbon dioxide (CO 2 ) supercritical refrigerants of refrigerants, and if figure 1 Shown are a compressor 1 , a heat removal device 2 , an intermediate heat exchanger 3 , an expansion valve 4 , an evaporator 5 and an accumulator 6 .

[0100] In this refrigeration cycle, the refrigerant in a supercritical state compressed by the compressor 1 releases heat by exchanging heat with refrigerant cooling air such as ambient air, while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com