Gasification unit for preparing biomass medium-heating value fuel gas

A gasification device and biomass technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of abnormal reaction, high cost and high calorific value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

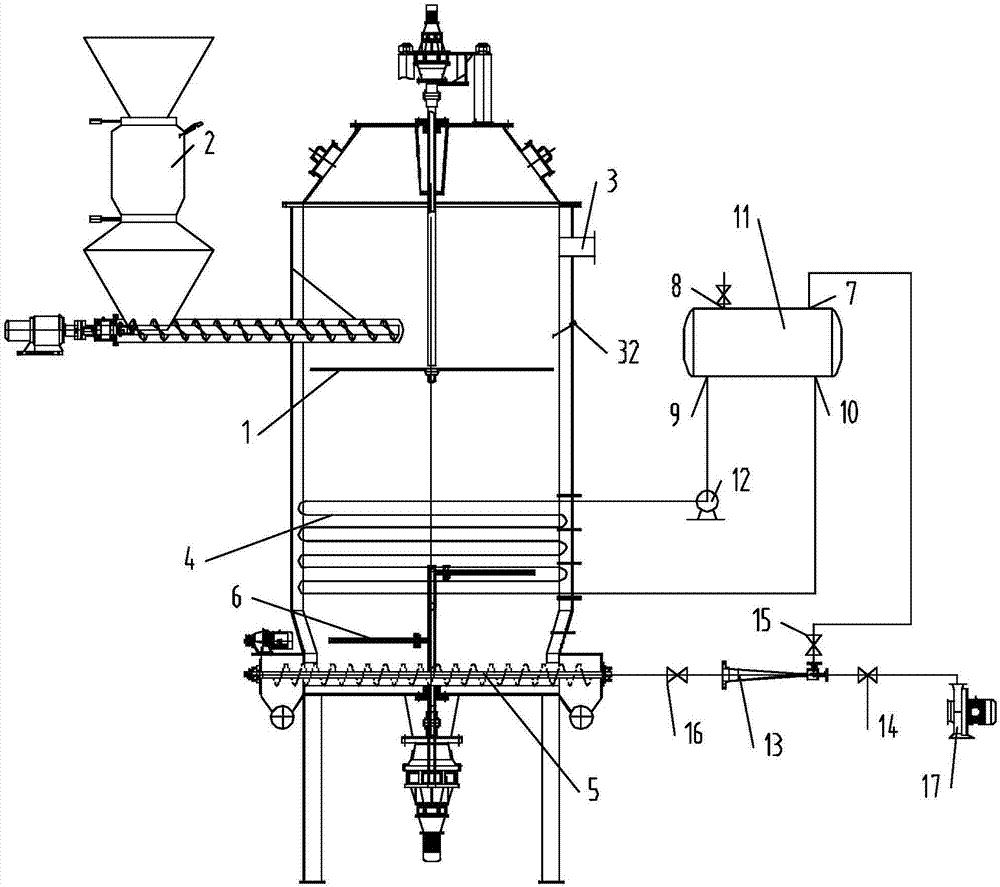

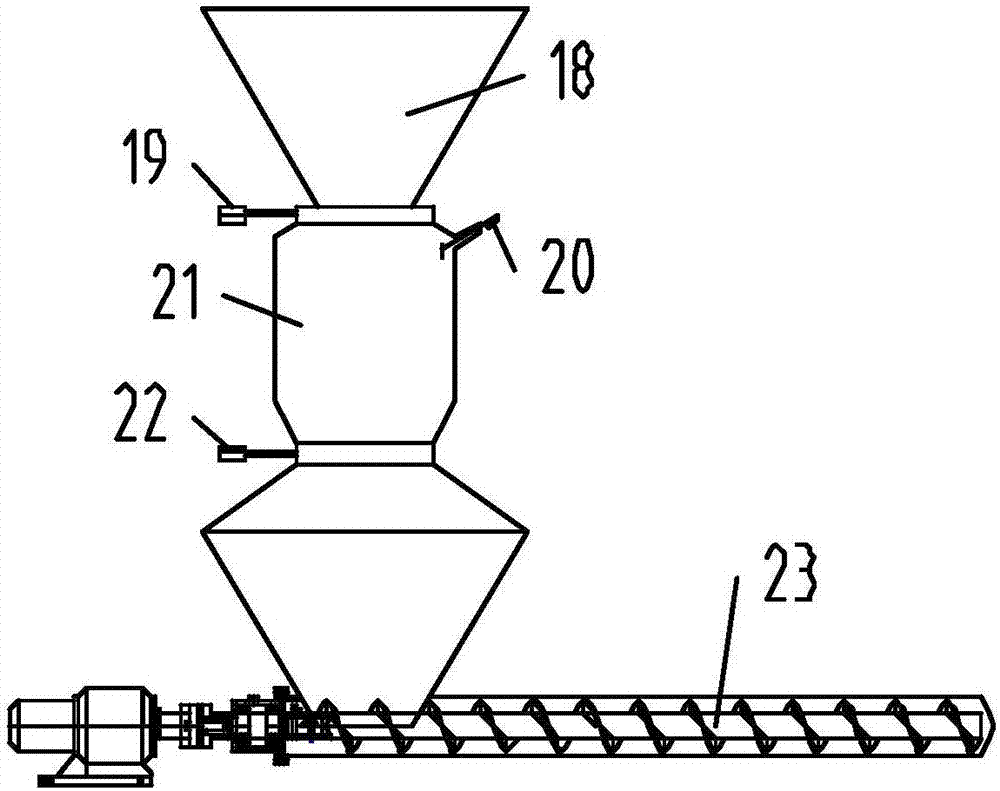

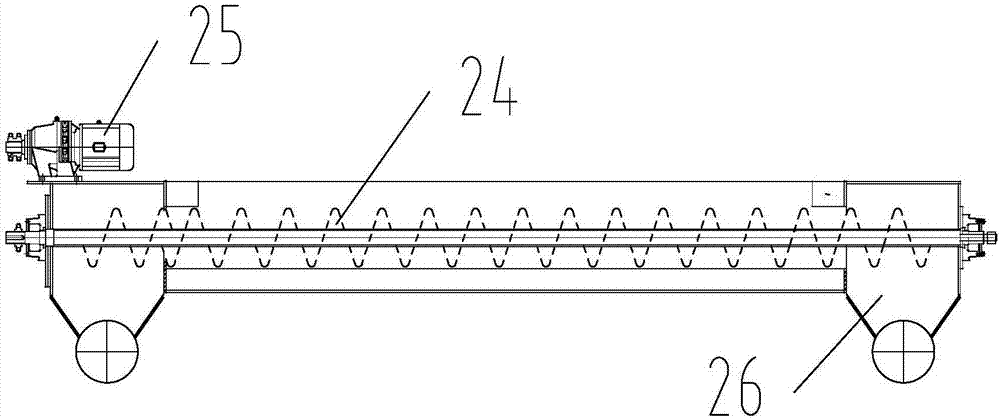

[0025] Control attached figure 1 In the shown gasification device for preparing biomass combustible gas with medium calorific value, a spreader 1 driven by a reducer is installed on the upper part of the gasifier to spread the gasification raw material in the closed feeding device 2, and the The airtight feeding device 2 controls its feeding according to the material level meter 32 installed on the gasifier body. A heating coil 4 is arranged on the furnace wall 300 mm above the spiral discharge gas distribution device 5. A breaker is installed at the lower part of the furnace body. The bridge device 6 is used to prevent bridging of the reaction layer.

[0026] The steam generation intake system is composed of a steam drum 11, a circulating hot water pump 12, a mixer 13, valves, a fan 17 and the like. The steam drum 11 is provided with a water supply port 8 , a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com