Film bulk acoustic resonator and preparation method thereof

A thin-film bulk acoustic wave and resonator technology, applied in the field of resonators, can solve the problems of acoustic energy leakage, incomplete acoustic impedance mismatch, etc., achieve high frequency stability, improve Q value, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

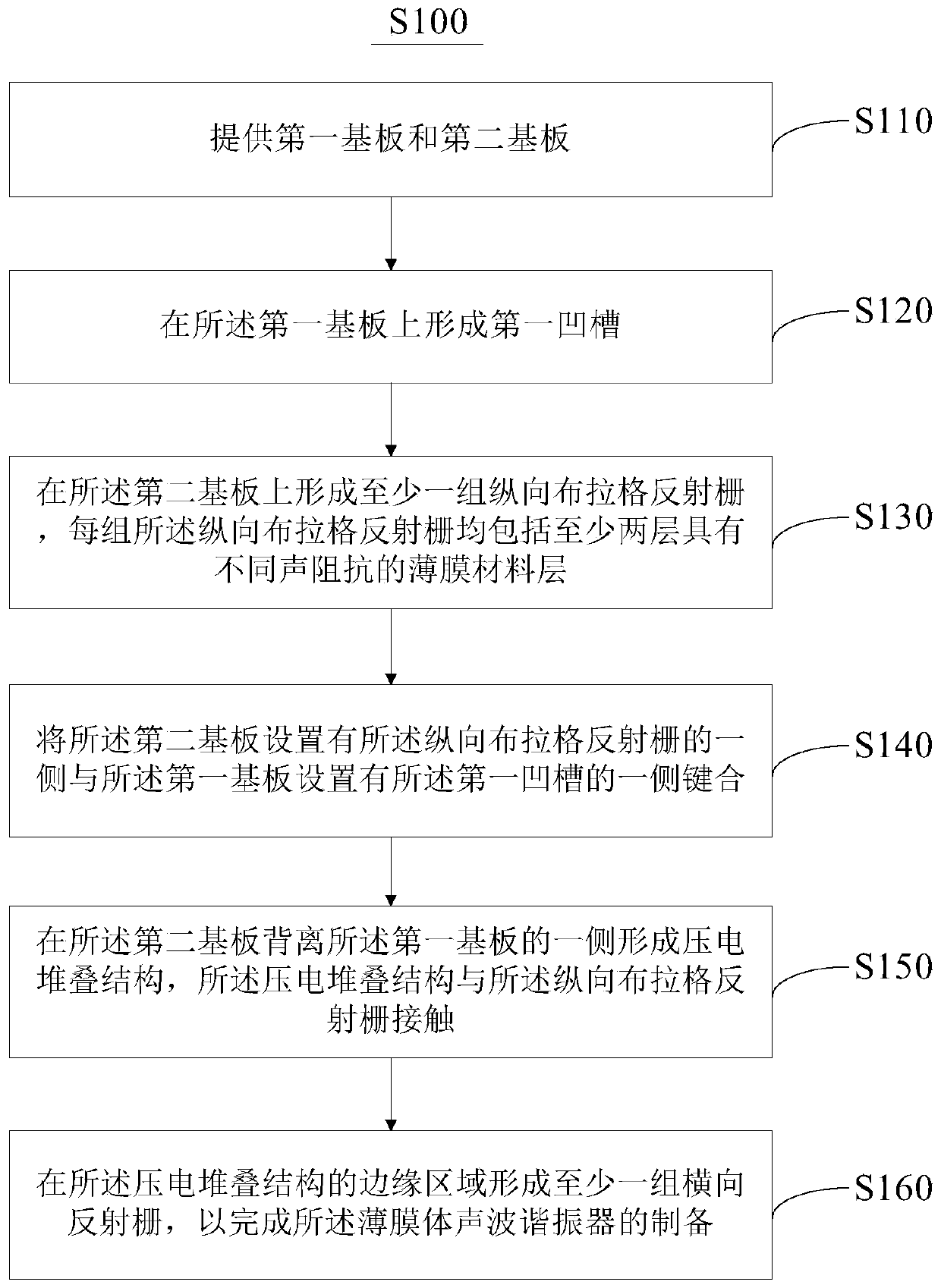

[0062] Such as figure 1 As shown, the first aspect of the present invention is a thin film bulk acoustic resonator manufacturing method S100, which specifically includes the following steps:

[0063] S110, providing a first substrate and a second substrate;

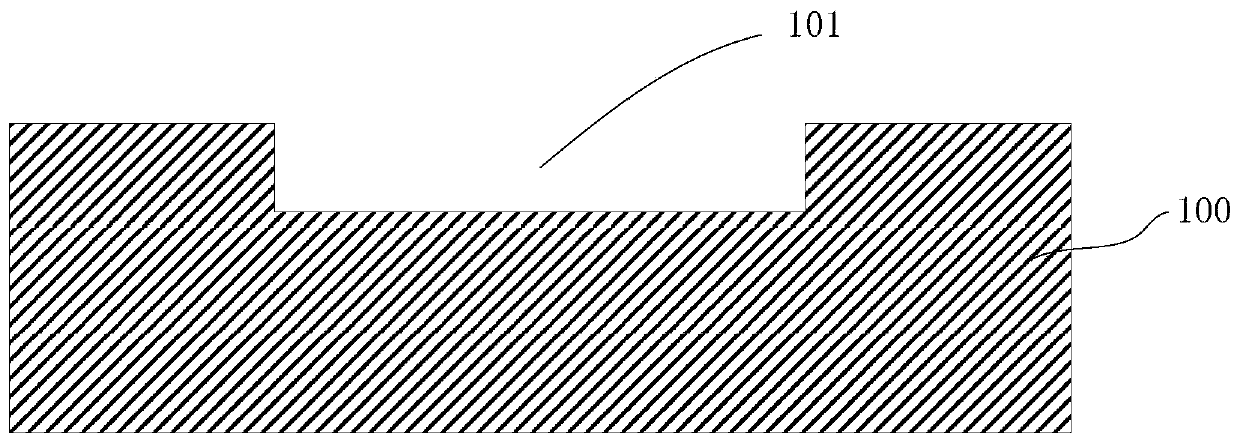

[0064] S120, forming a first groove on the first substrate;

[0065] S130. Form at least one set of longitudinal Bragg reflection gratings on the second substrate, each set of longitudinal Bragg reflection gratings includes at least two thin film material layers with different acoustic impedances;

[0066] S140, bonding the side of the second substrate provided with the longitudinal Bragg grating to the side of the first substrate provided with the first groove;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com