Patents

Literature

43 results about "Energy trapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

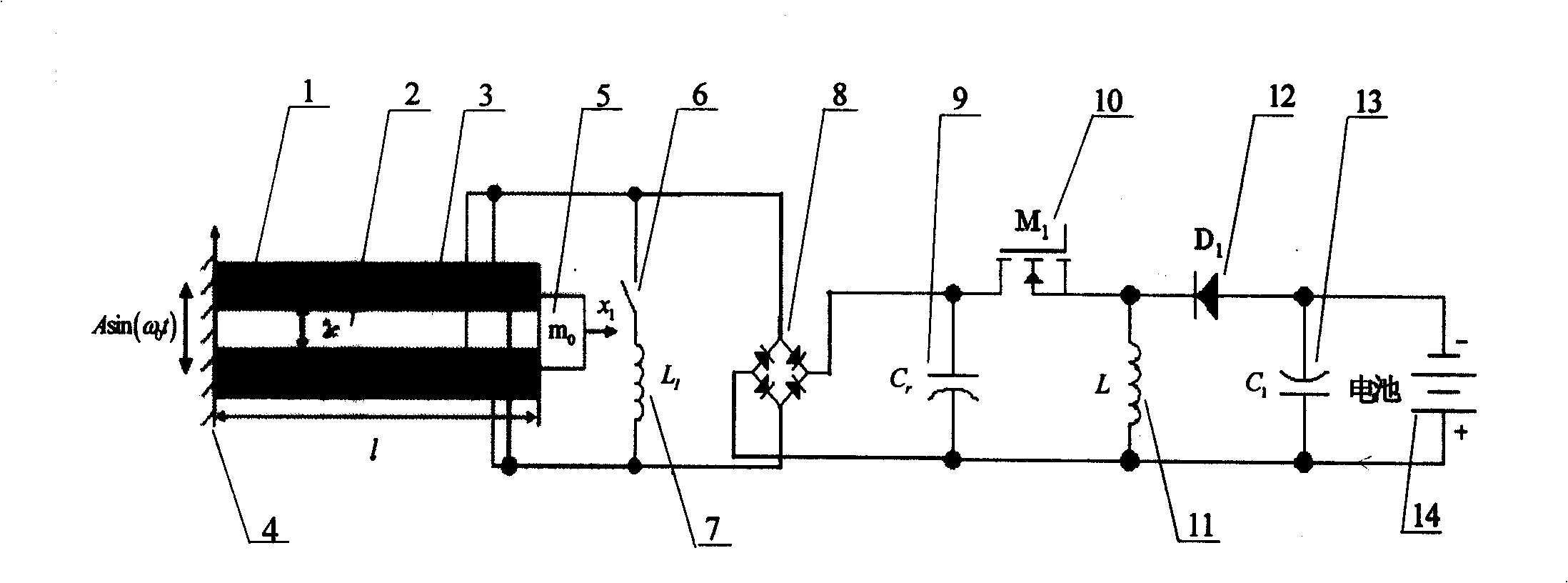

Piezoelectric energy trapping device capable of efficient trapping energy and energy-storaging

InactiveCN1848589AEfficient storageDuty cycle adjustableBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesTrappingEngineering

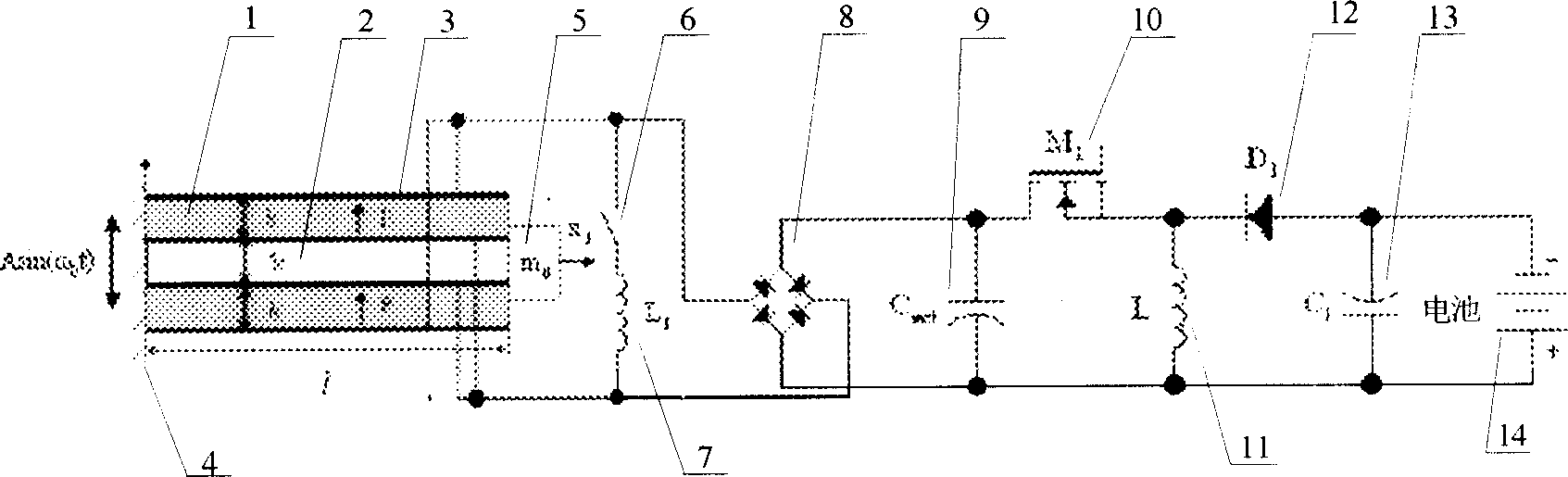

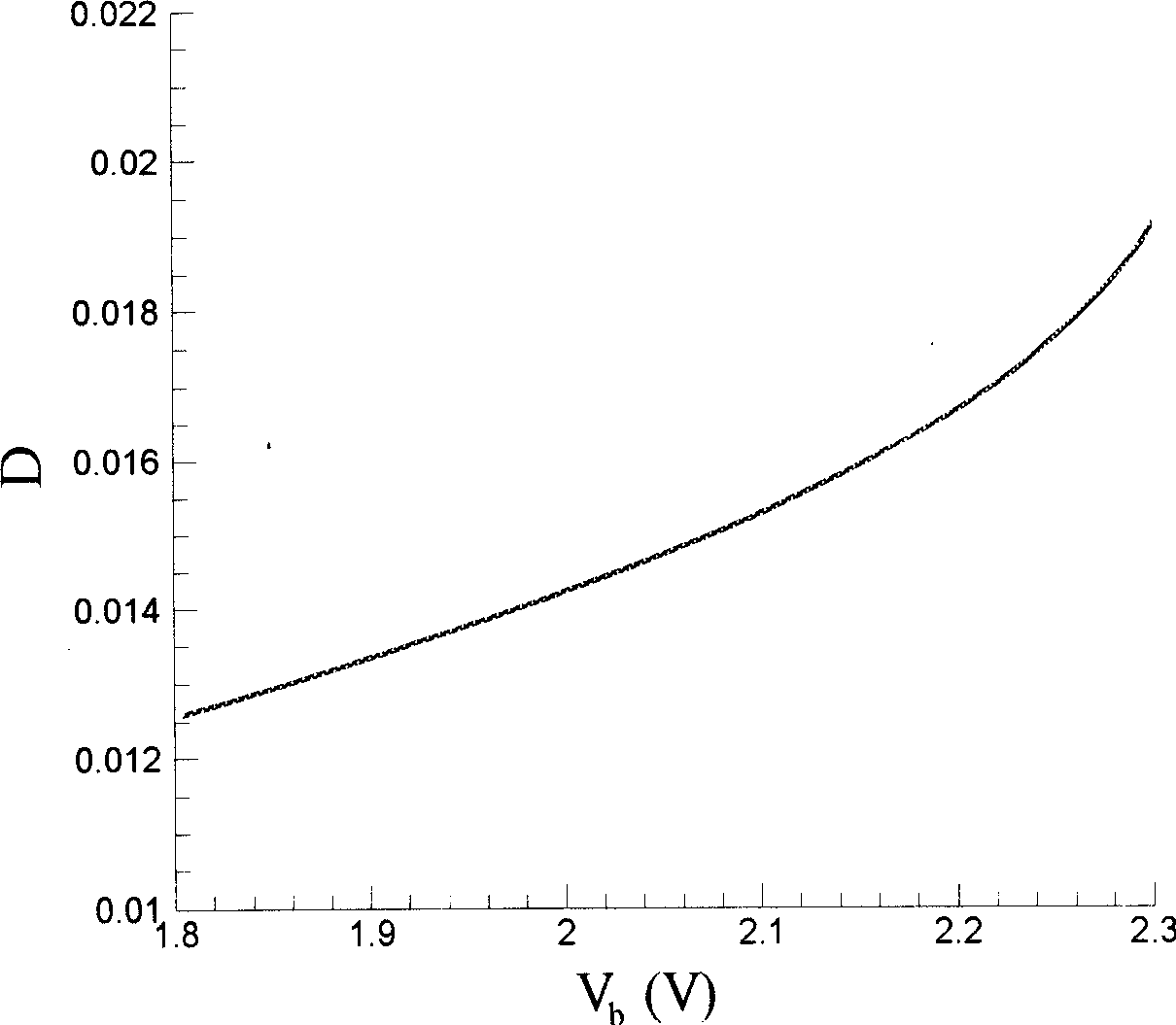

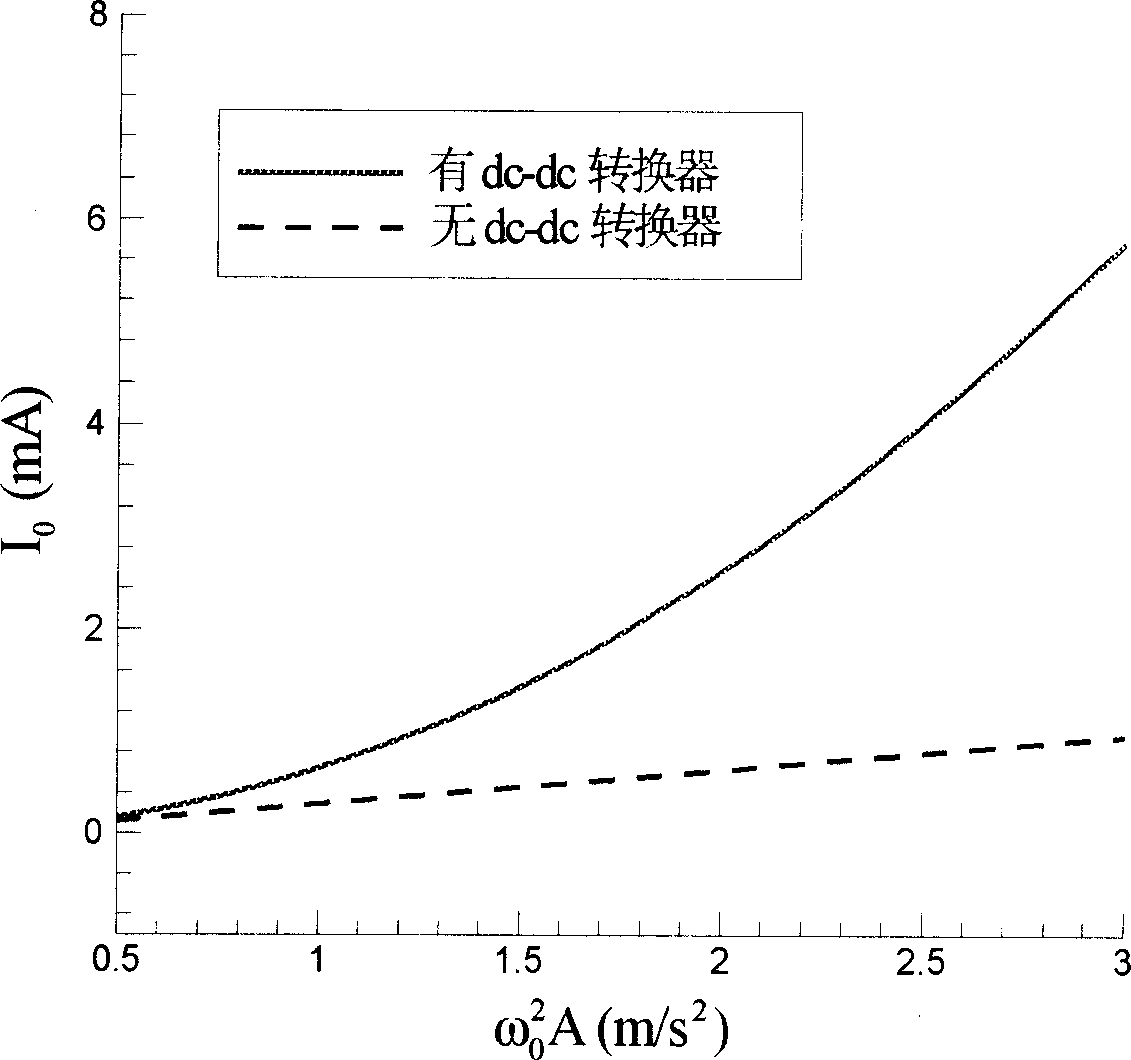

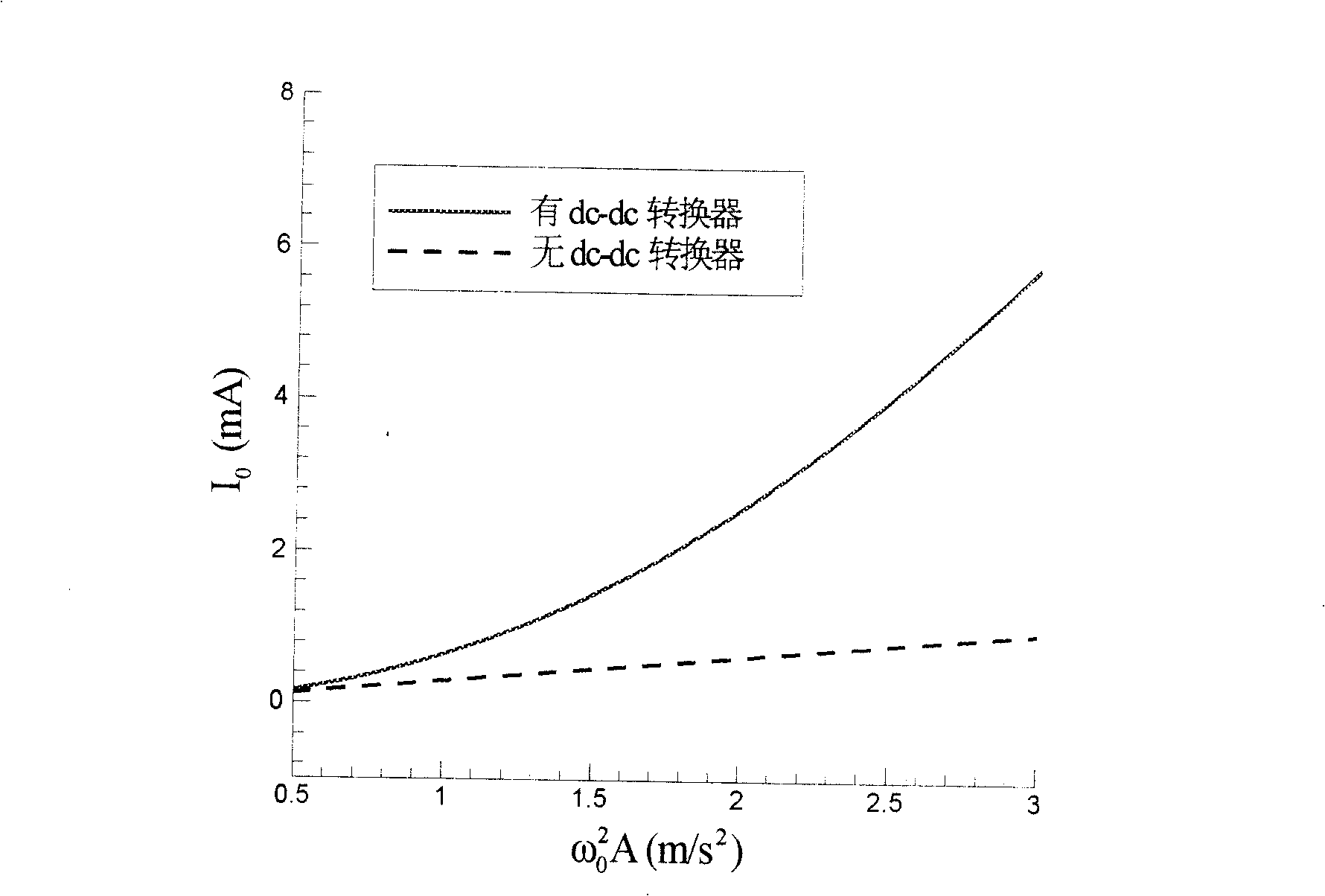

A piezoelectric energy captor enabling to capture energy and store energy effectively consists of piezoelectric beam formed by two layers of piezoelectric ceramic plates and intermediate sandwich layer, electrode prepared by plating metal silver on ceramic plate, inductance coil with control switch, bridge type of rectifier, rectifying capacitor, Cuk type of dc-dc converter formed by transistor switch and electric inductance as well as diode, filtering capacitor for stabilizing charge current, and energy storing battery.

Owner:CENT SOUTH UNIV

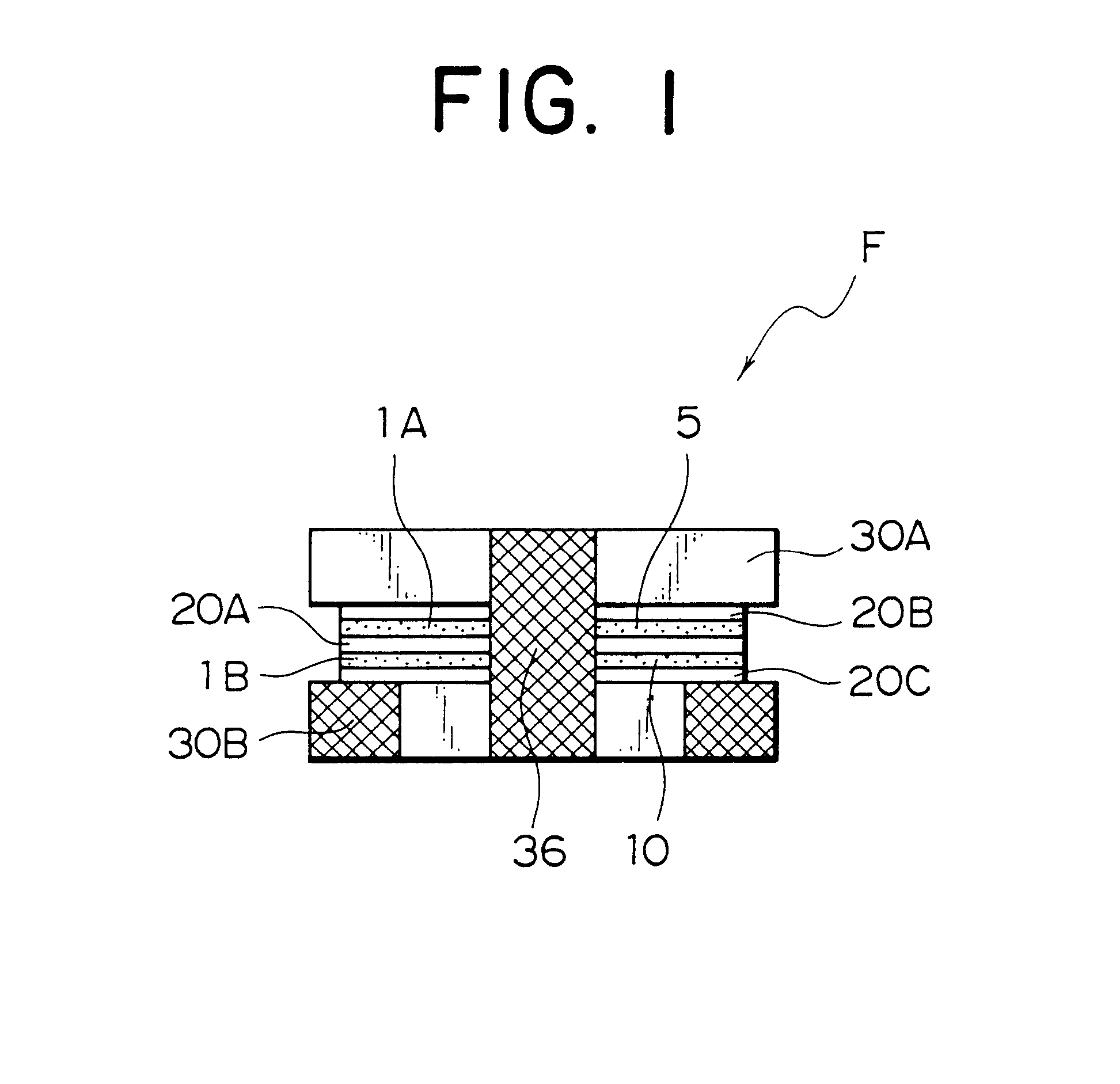

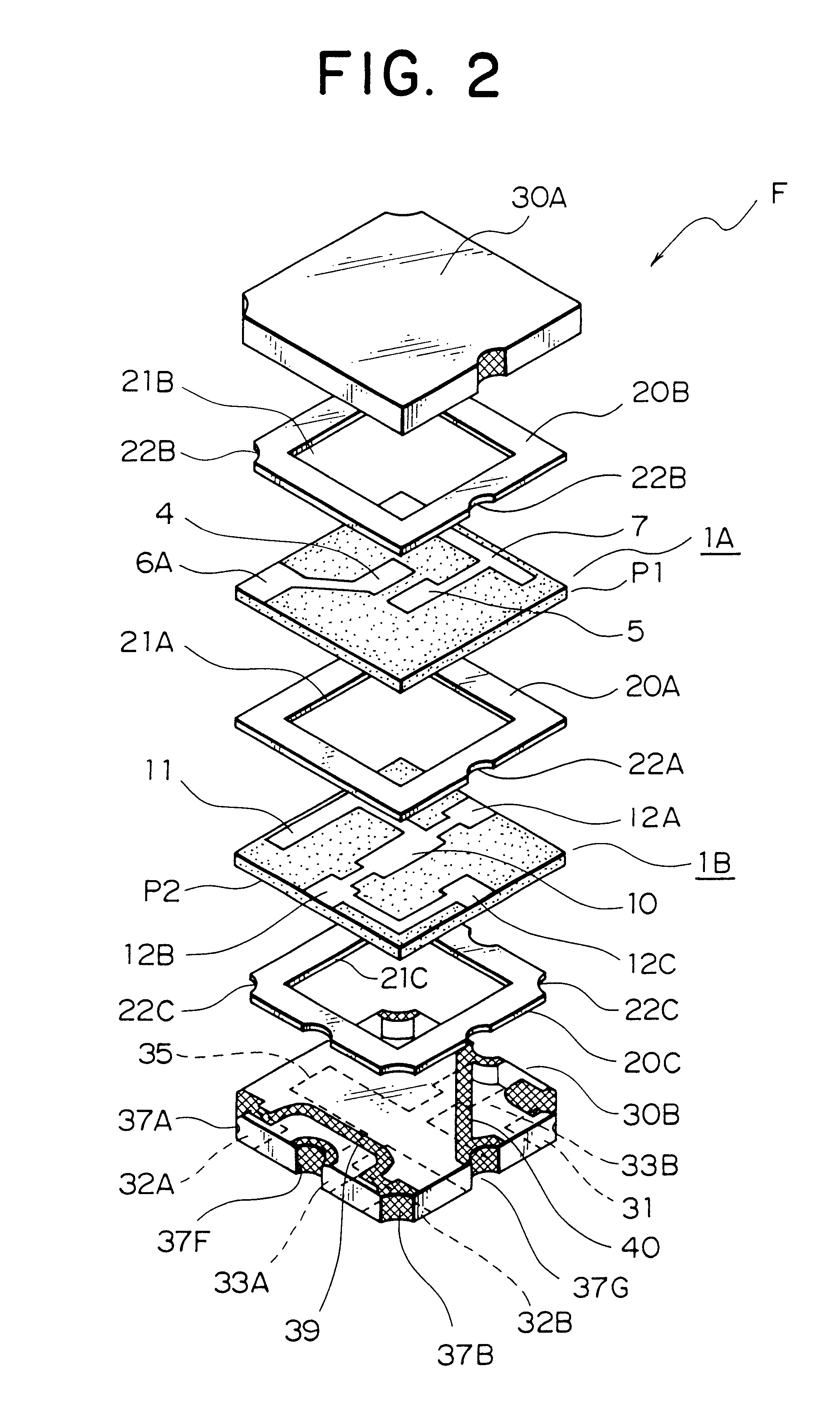

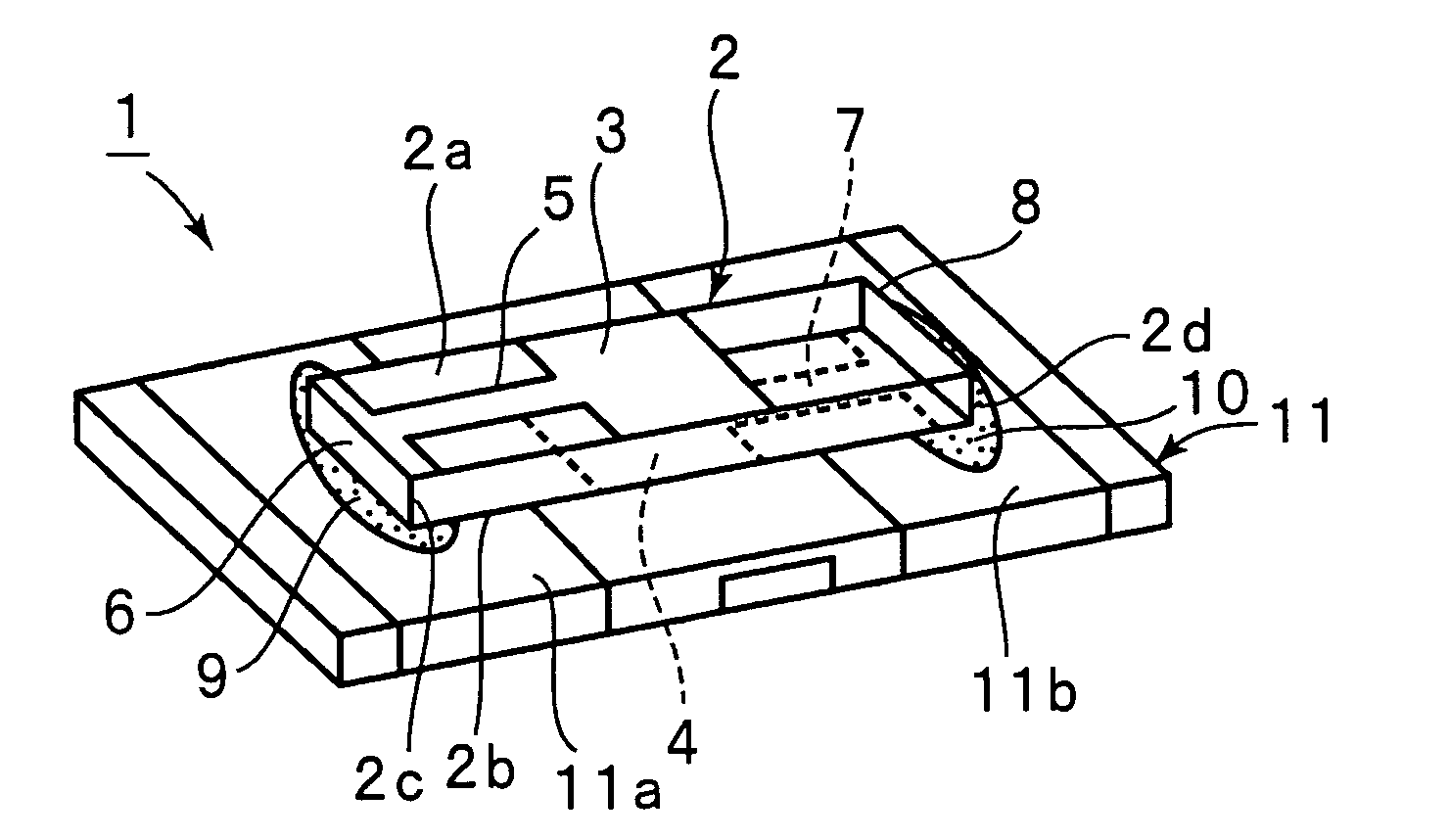

Energy trapping type piezoelectric filter with a shielding conductive member on a bottom insulating base plate upper surface

InactiveUS6359532B1Improve featuresReduce couplingPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectromagnetic couplingGrounding electrodes

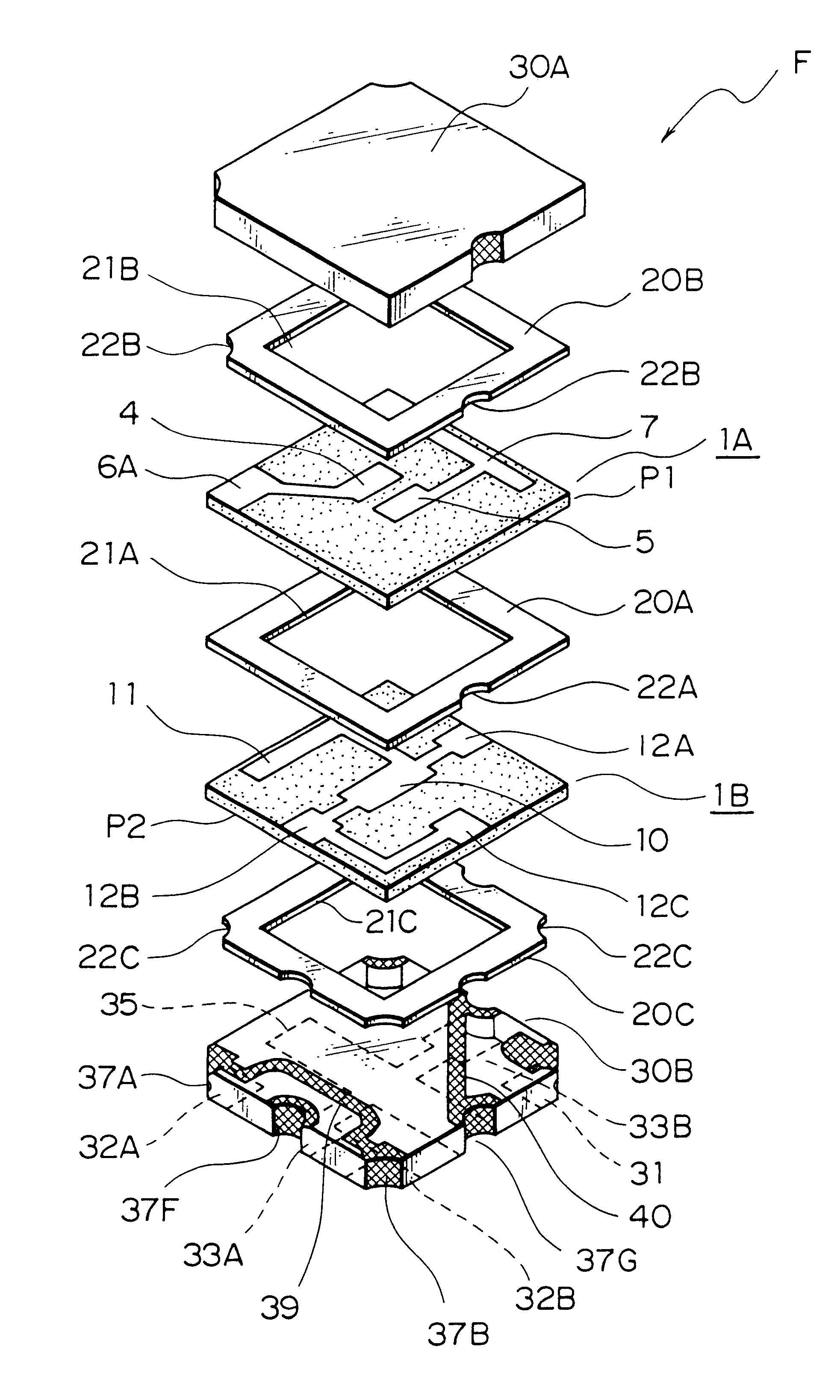

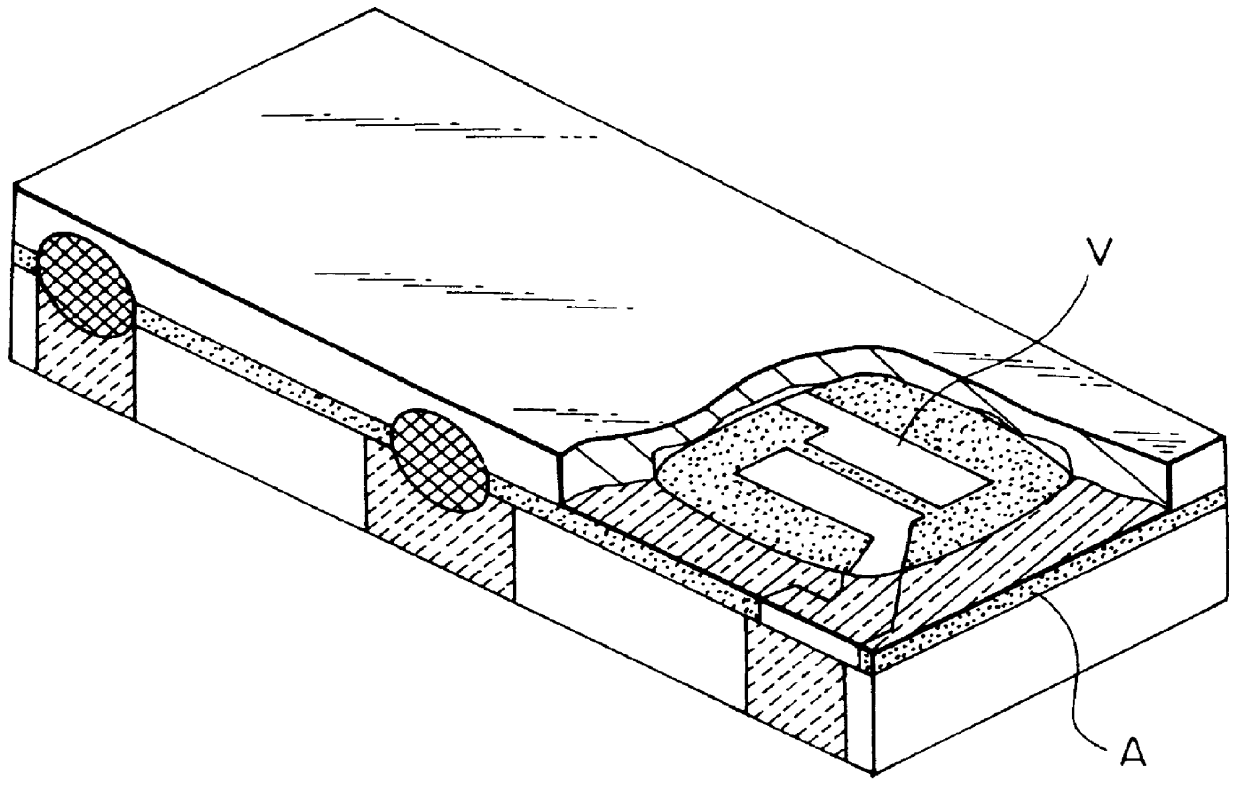

An energy trapping type piezoelectric filter comprising a first piezoelectric substrate (1A) and a second piezoelectric substrate (1B) having an identical configuration and arranged in layers with an adhesive sheet or spacer (20A) interposed therebetween and insulating top and base plates (30A, 30B) arranged on and under the respective piezoelectric substrates with adhesive sheets or spacers (20B, 20C) also interposed therebetween, wherein a shielding conductive member (40) is provided on an upper surface of the insulating base plate (30B) for preventing an electromagnetic coupling between an input electrode (31) and output electrodes (32A, 32B), the shielding conductive member (40) being connected to grounding electrodes (33A, 33B).

Owner:NGK SPARK PLUG CO LTD

Piezoelectric energy trapping device capable of efficient trapping energy and energy-storaging

InactiveCN100414808CEfficient storageDuty cycle adjustableBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesTrappingEngineering

A piezoelectric energy captor enabling to capture energy and store energy effectively consists of piezoelectric beam formed by two layers of piezoelectric ceramic plates and intermediate sandwich layer, electrode prepared by plating metal silver on ceramic plate, inductance coil with control switch, bridge type of rectifier, rectifying capacitor, Cuk type of dc-dc converter formed by transistor switch and electric inductance as well as diode, filtering capacitor for stabilizing charge current, and energy storing battery.

Owner:CENT SOUTH UNIV

Energy trapping type piezoelectric filter with identical piezoelectric substrates

InactiveUS6160462AImprove attenuation characteristicsReduced characteristicsPiezoelectric/electrostriction/magnetostriction machinesImpedence networksCapacitanceElectromagnetic coupling

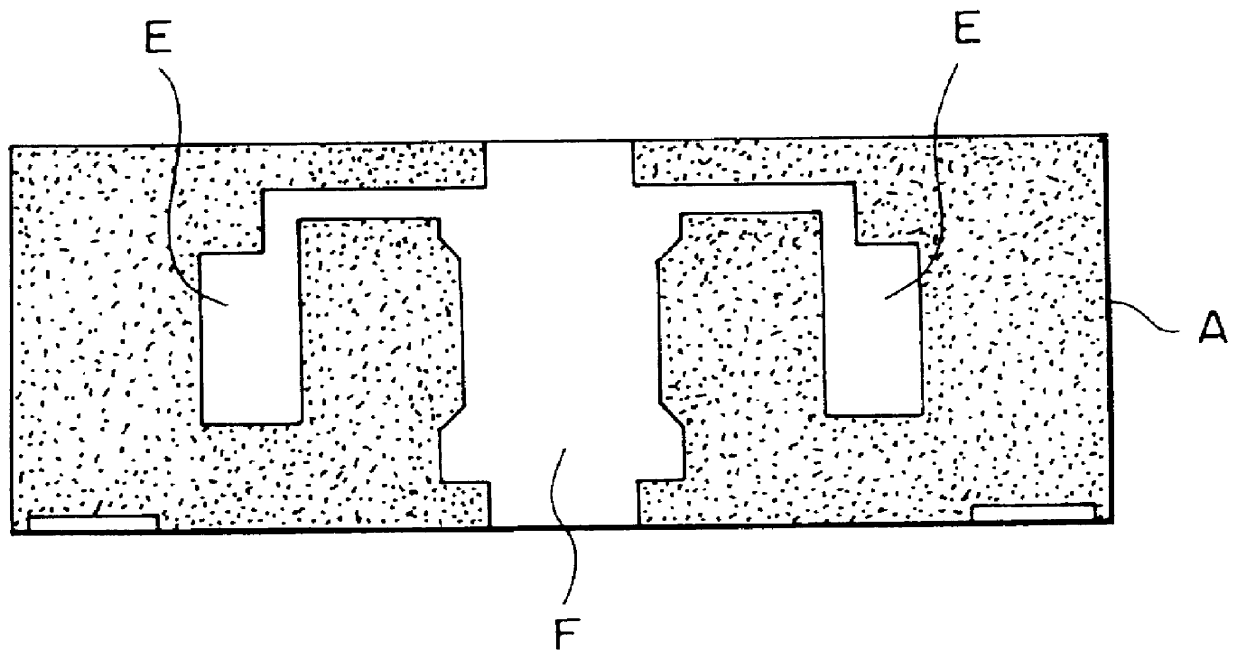

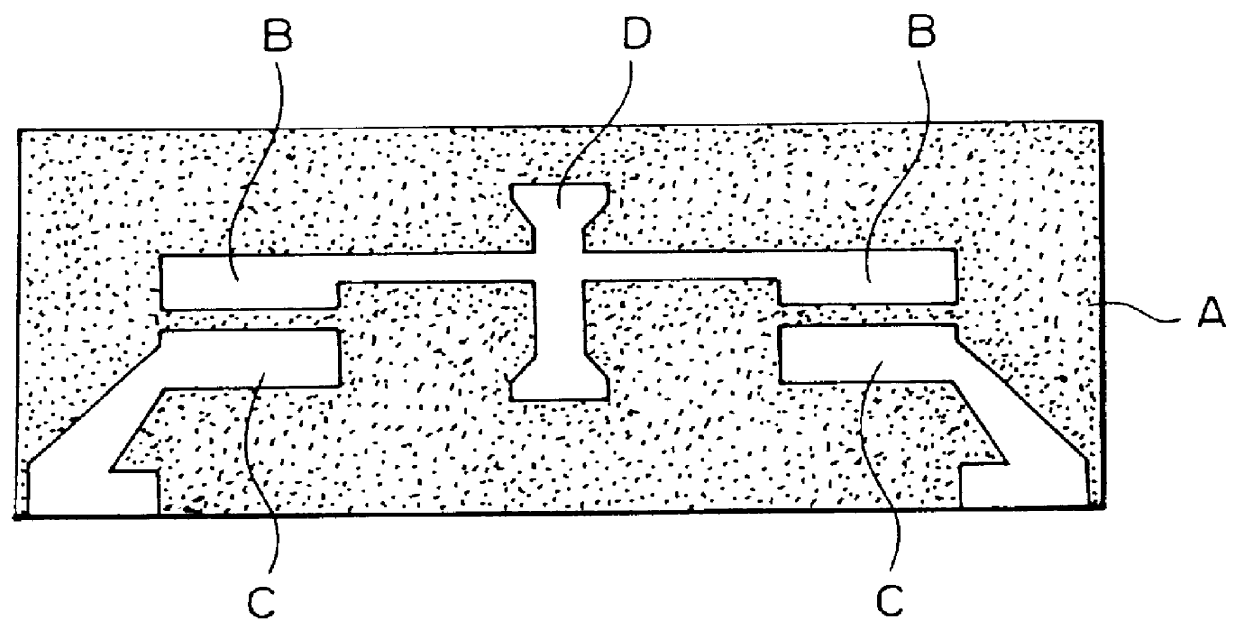

An energy trapping type piezoelectric filter having a minimal surface area comprises a first and second identical piezoelectric substrates 10a and 10b being laid one on the other to form a multilayer structure, each having a first surface provided with a pair of oscillatory electrodes 11 and 12 arranged vis-a-vis relative to each other and a capacitor electrode 14 which is connected to one of the oscillatory electrodes 12, the other oscillatory electrode 11 being electrically connected to an input / output connection terminal 13 also arranged on the first surface, and a second surface provided with a common electrode 16 arranged oppositely relative to said pair of oscillatory electrodes 11 and 12 and a capacitor electrode 17 arranged opposite to said capacitor electrode 14, the capacitor electrode 17 and the common electrode 16 being electrically connected to each other, the pair of oscillatory electrodes 11 and 12 and the common electrode 16 forming an oscillating section V, the capacitor electrodes 14 and 17 forming a coupling capacitor C1 (C2). The energy trapping type piezoelectric filter further may comprise a shield electrode means 19 and 34 for any electromagnetic coupling of a pair of input / output electrodes and / or terminals.

Owner:NGK SPARK PLUG CO LTD

Intelligent MPPT (maximum power point tracking) wind energy controller

InactiveCN102477943AImprove stabilityAvoiding the Difficulties of Accurate Wind Velocity MeasurementsWind motor controlMachines/enginesElectricityIntegrator

The invention provides an intelligent type MPPT (maximum power point tracking) wind energy controller which comprises a slip form extremum search module and a blur parameter setting module, wherein the parameter of the slip form extremum search module is adjusted according to the output of the blur parameter setting module; the slip form extremum search module comprises a comparing unit, a switching unit and two integrators, and the blur parameter setting module comprises a fuzzy controller; and the parameter of the switching unit is set by the output of the fuzzy controller, and the input of the fuzzy controller is a power tracking error e and wind speed V of a wind power system. The wind energy controller provided by the invention can provide an optima rotation rate reference value for realizing maximize wind energy trapping of the wind power system, and can effectively restrain the neighbouring system disturbance of a maximum power.

Owner:HUIZHOU SANHUA IND

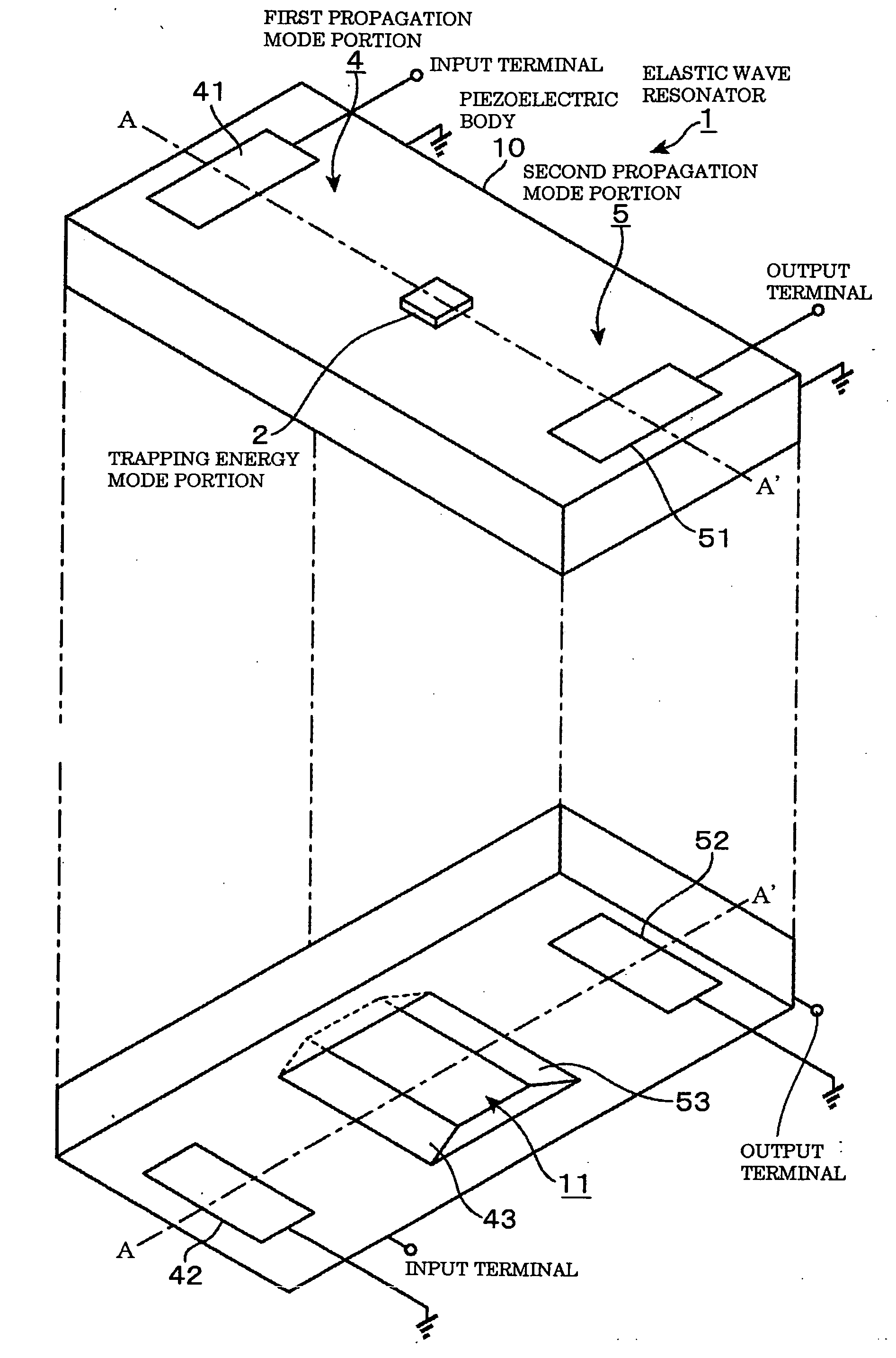

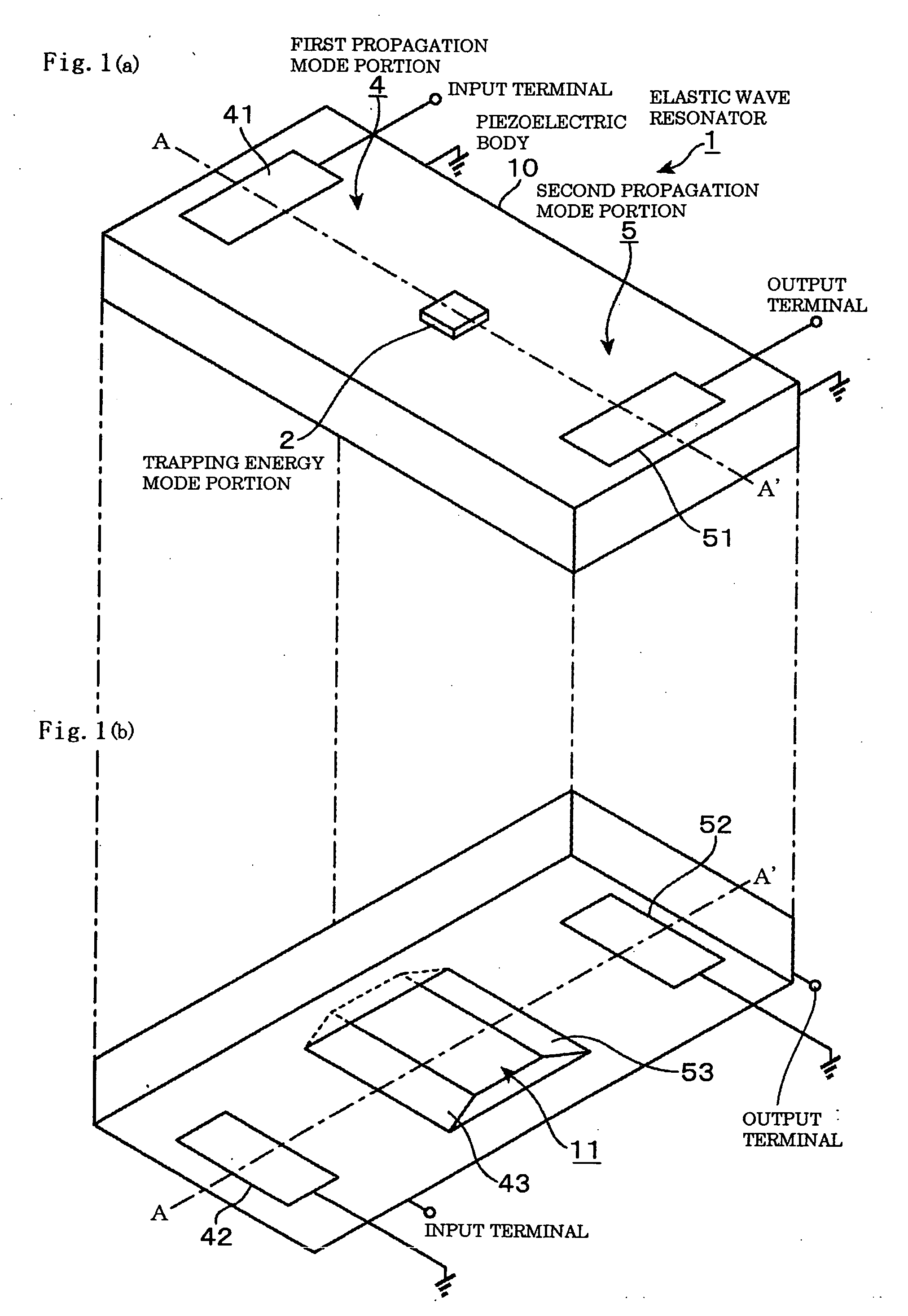

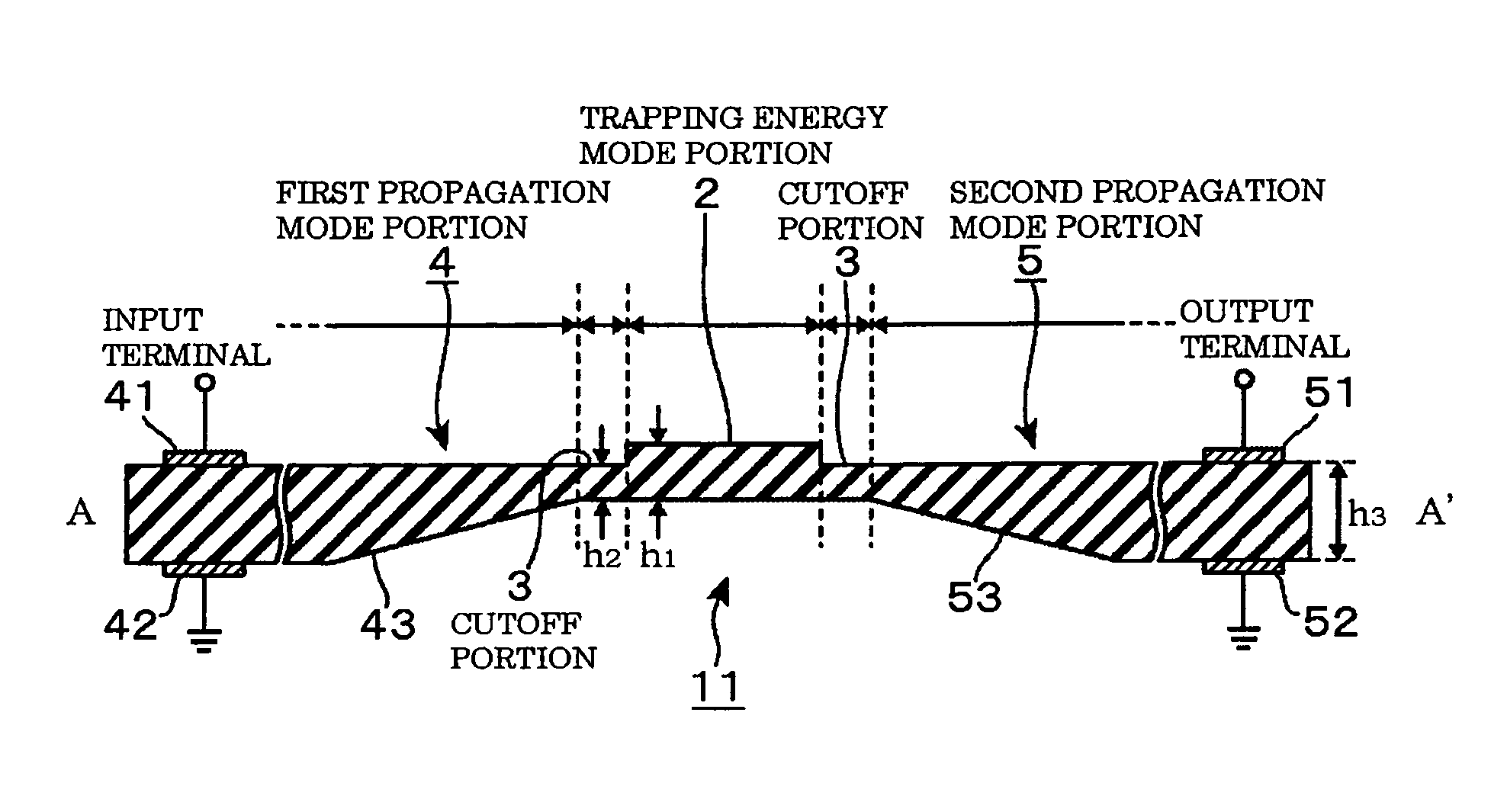

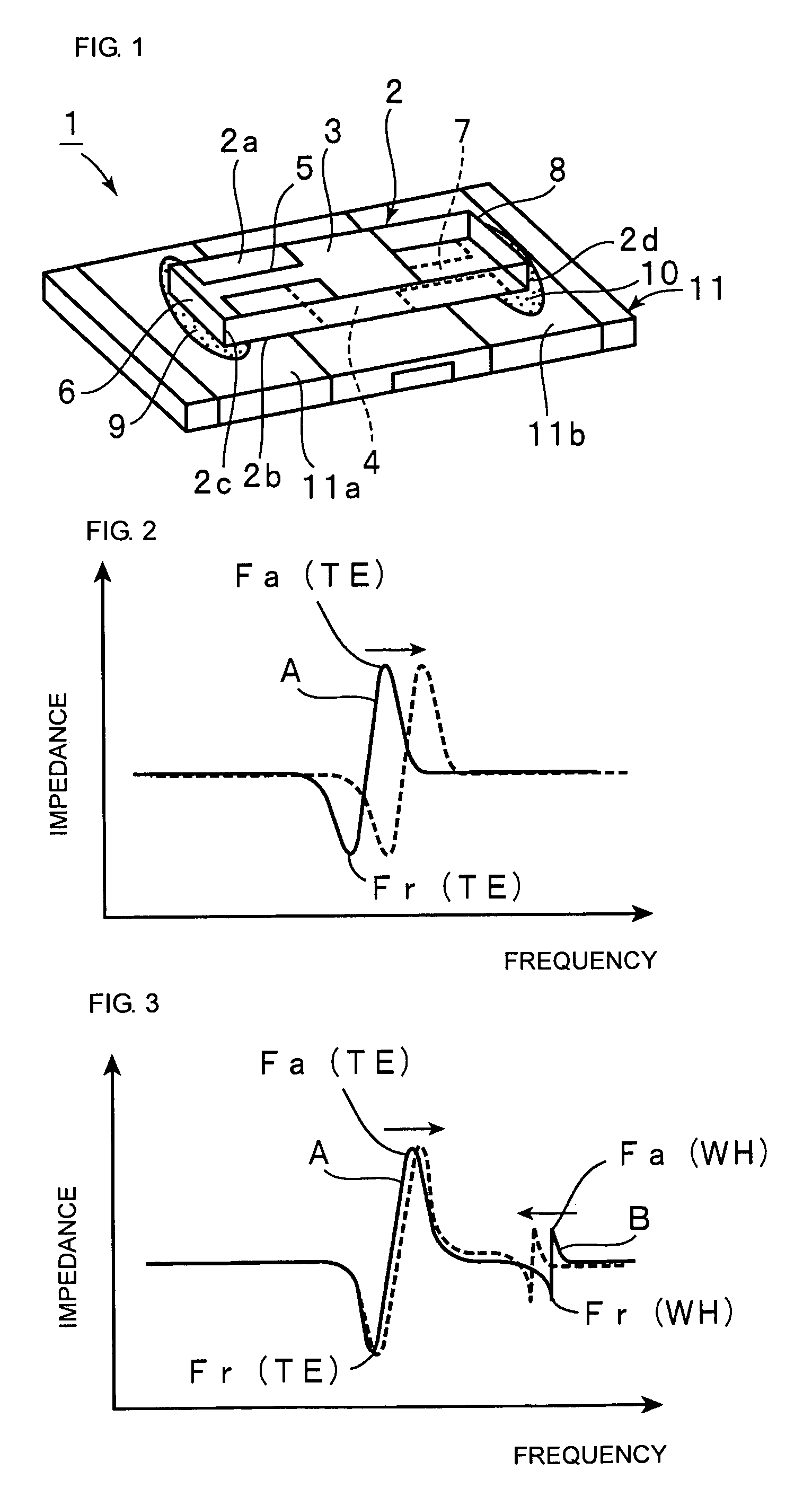

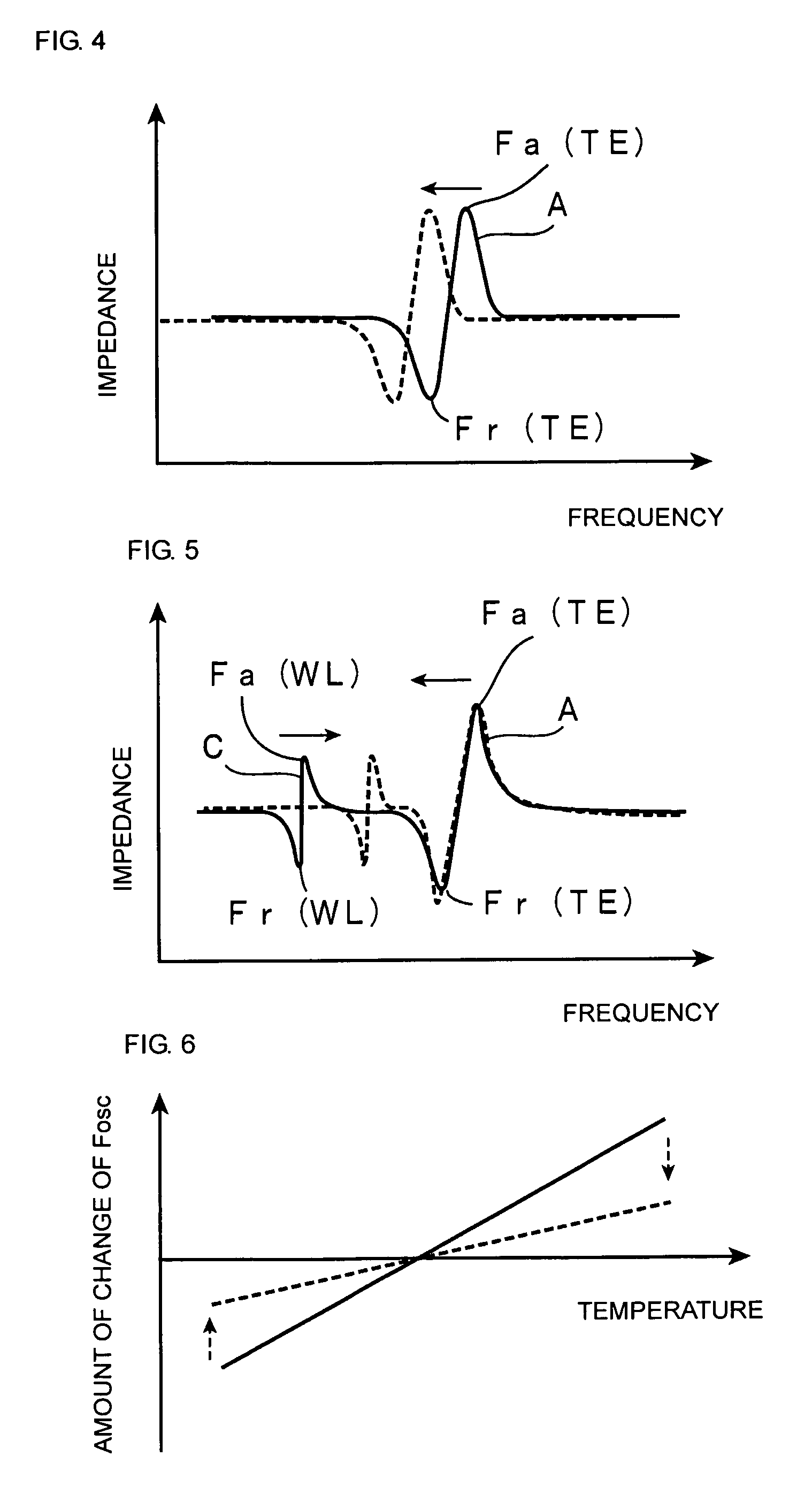

Elastic wave device and electronic component

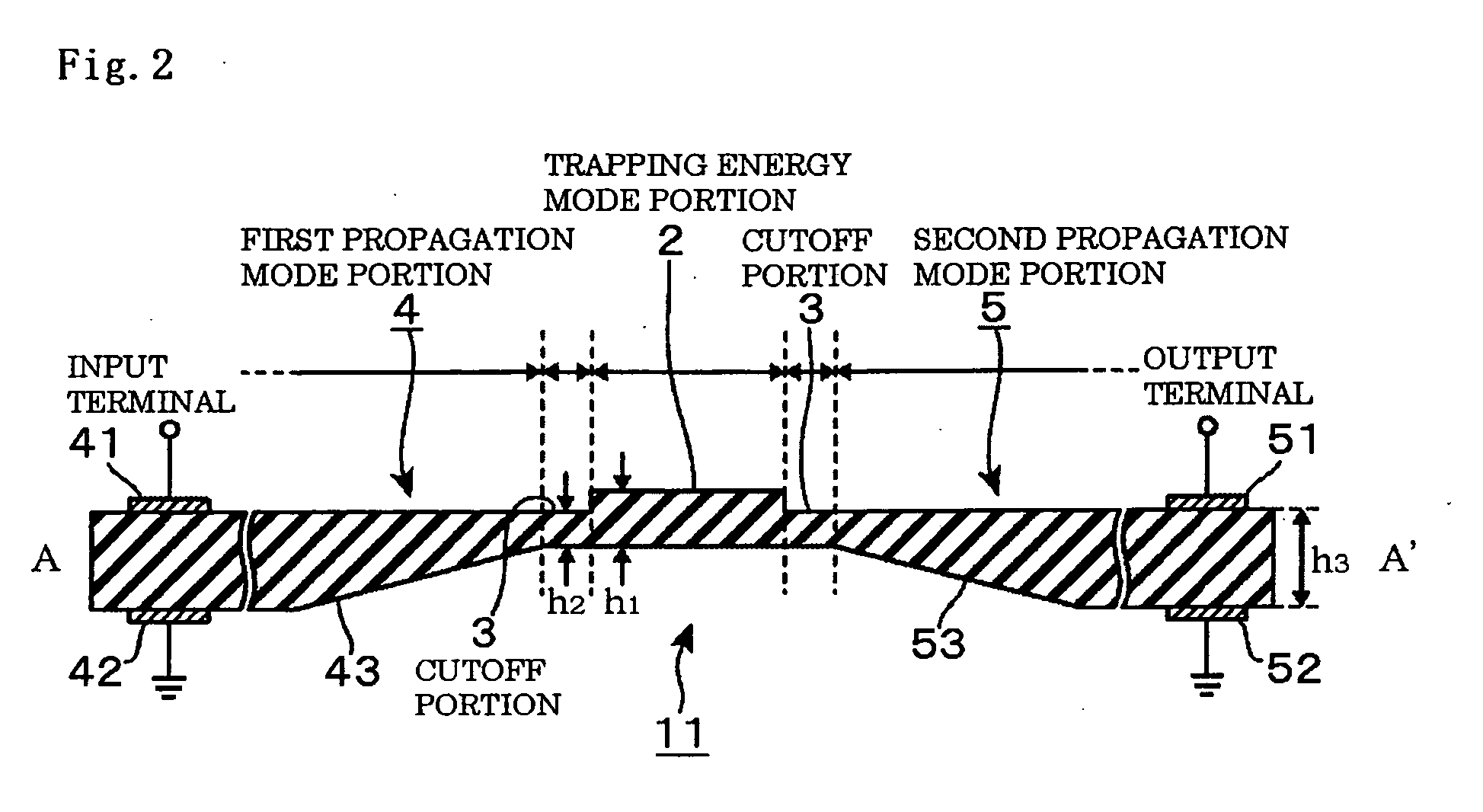

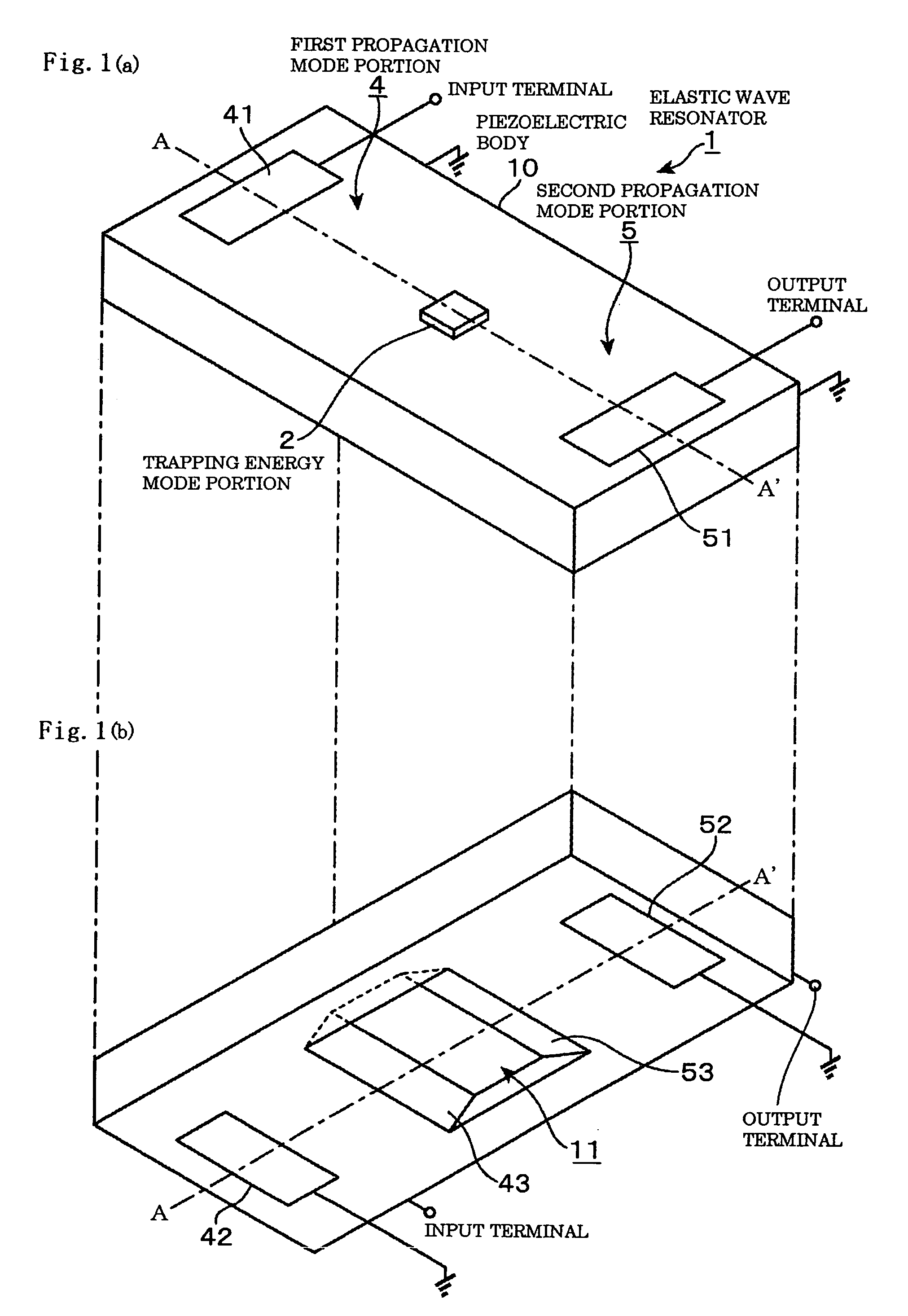

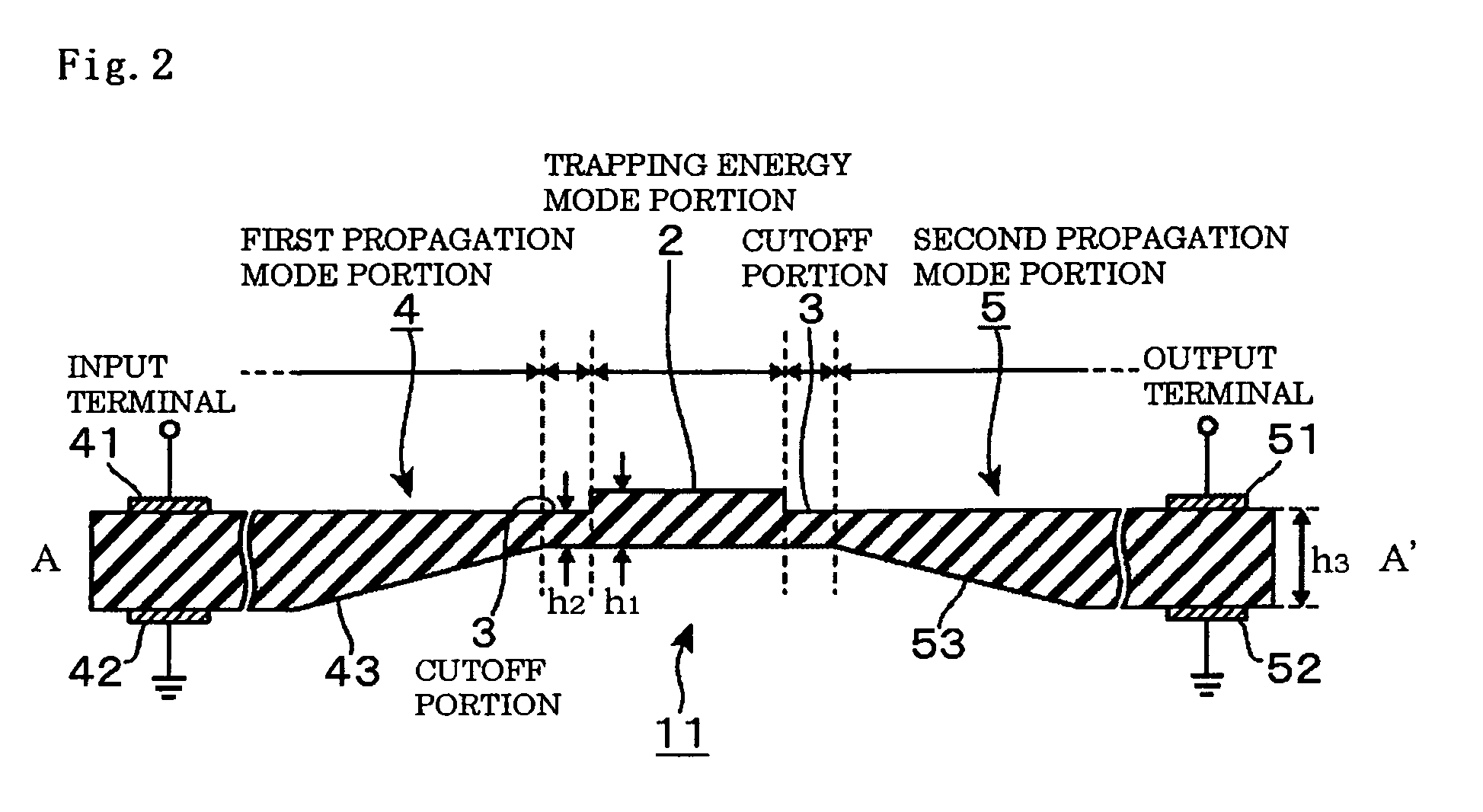

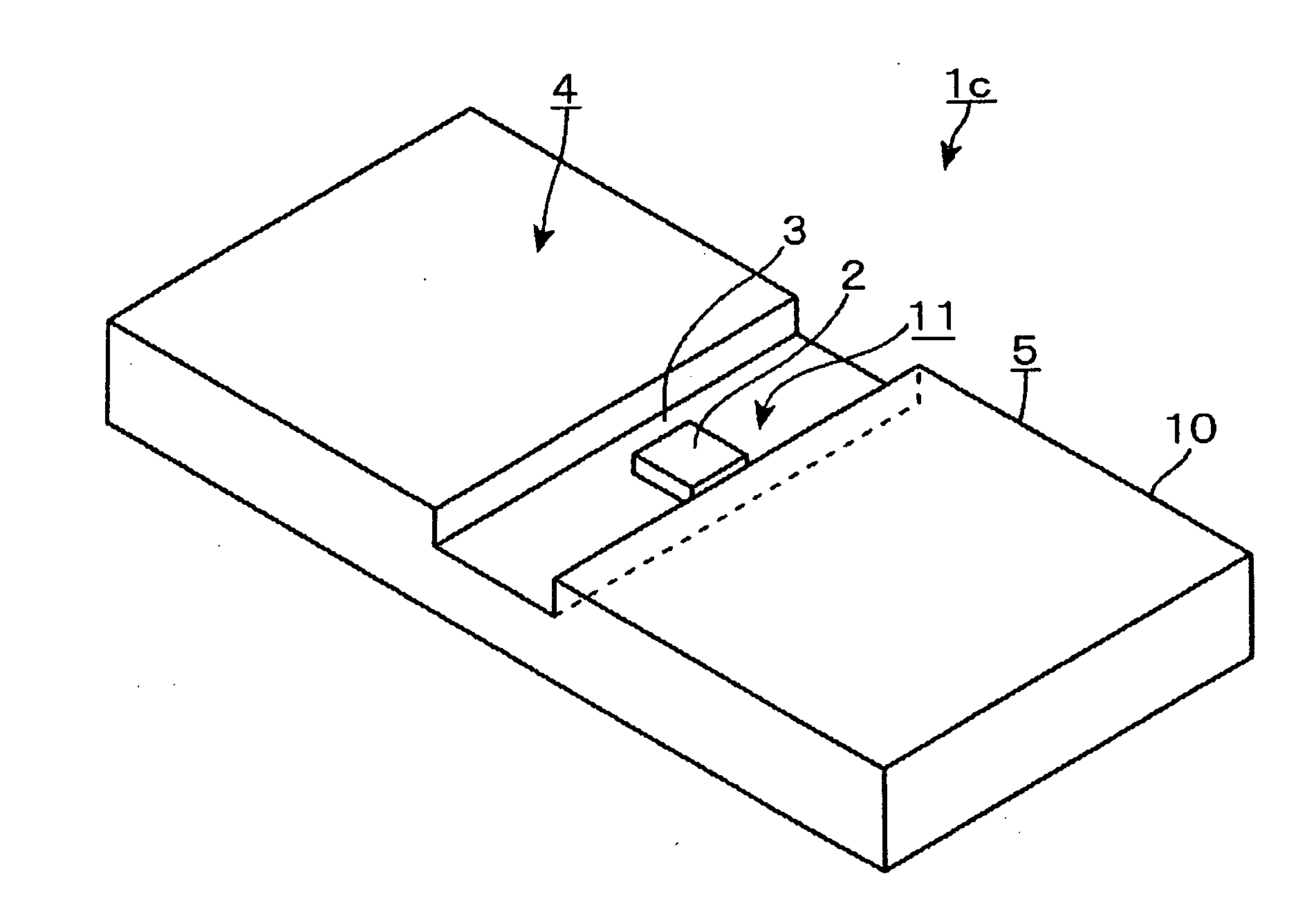

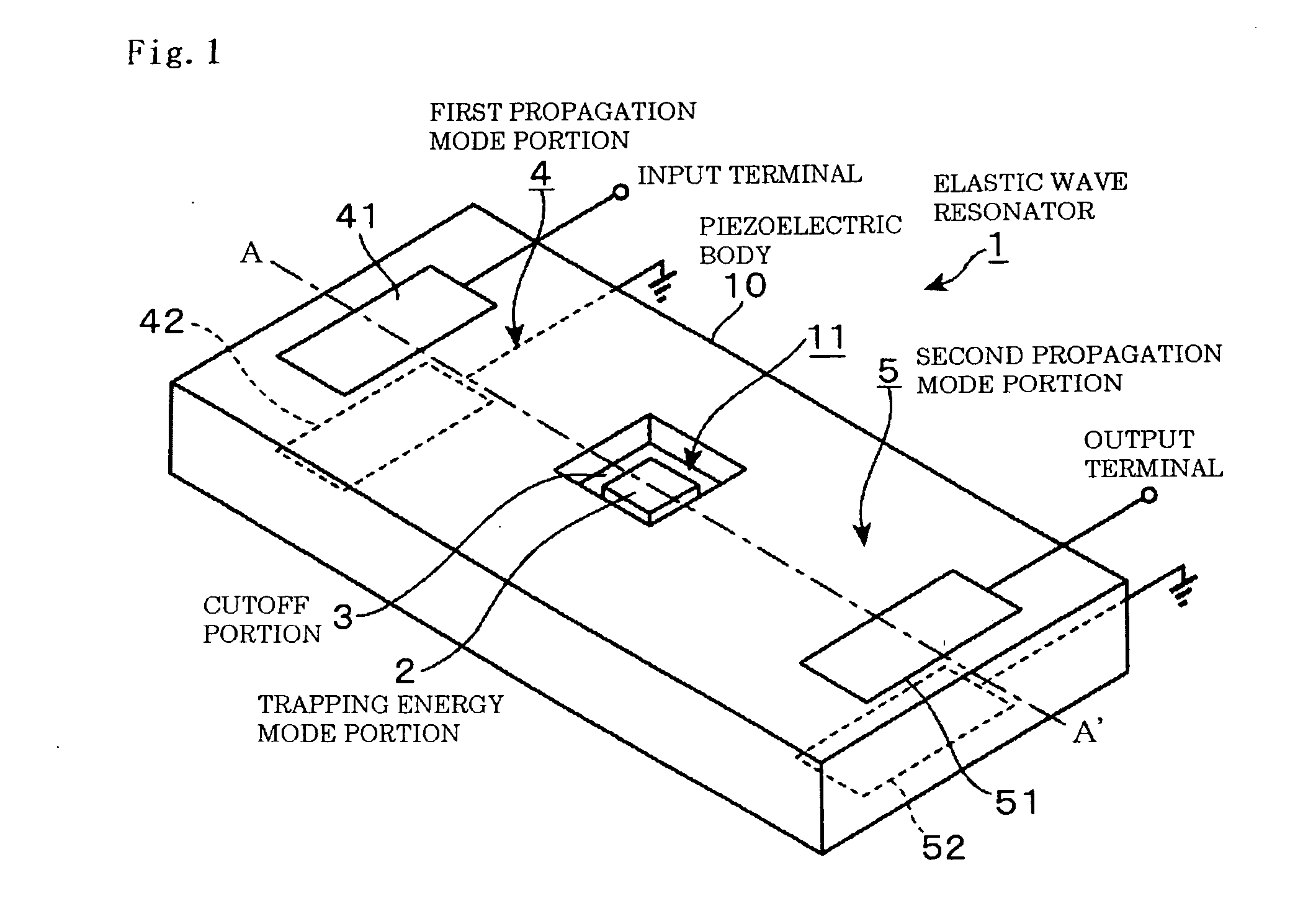

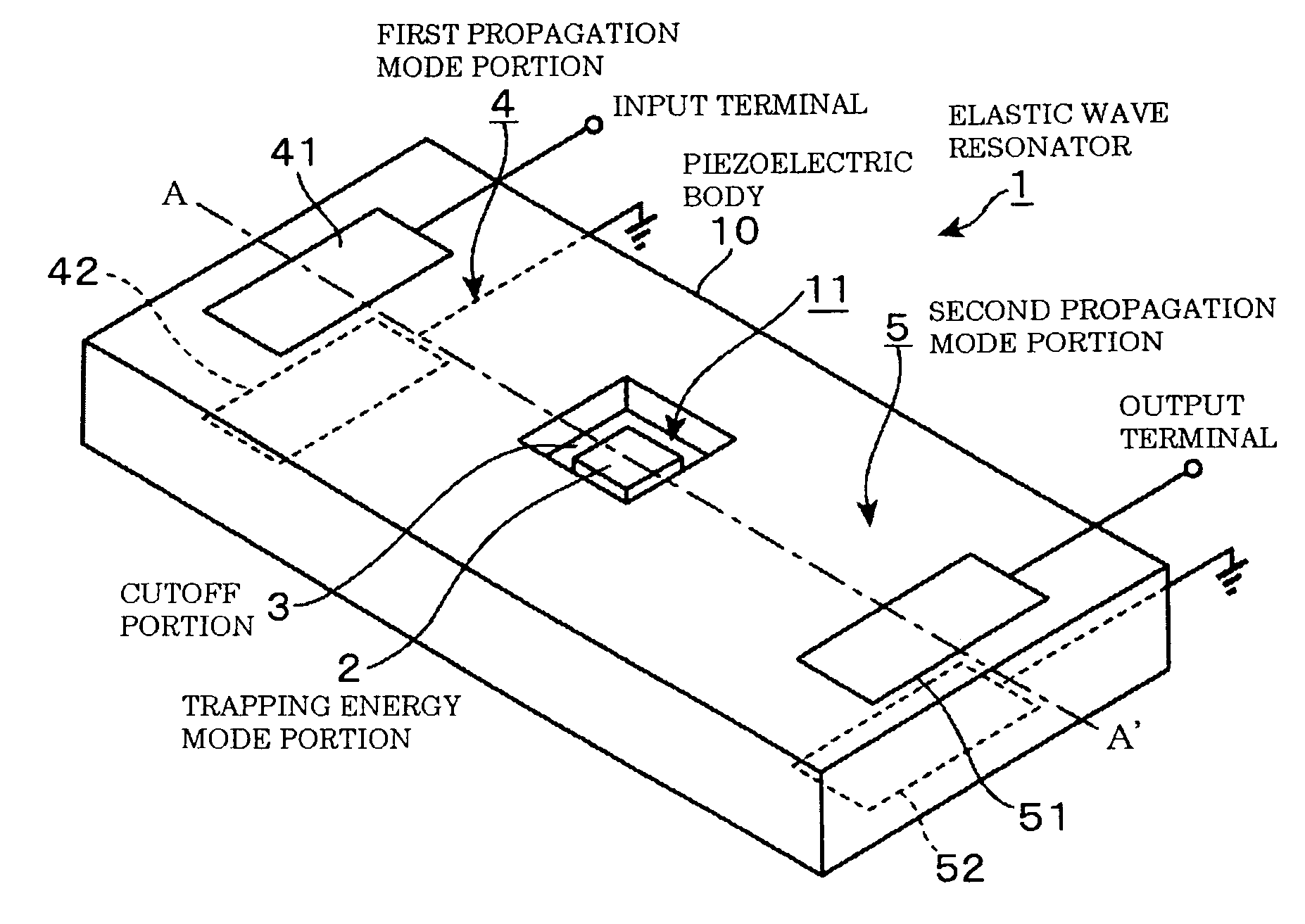

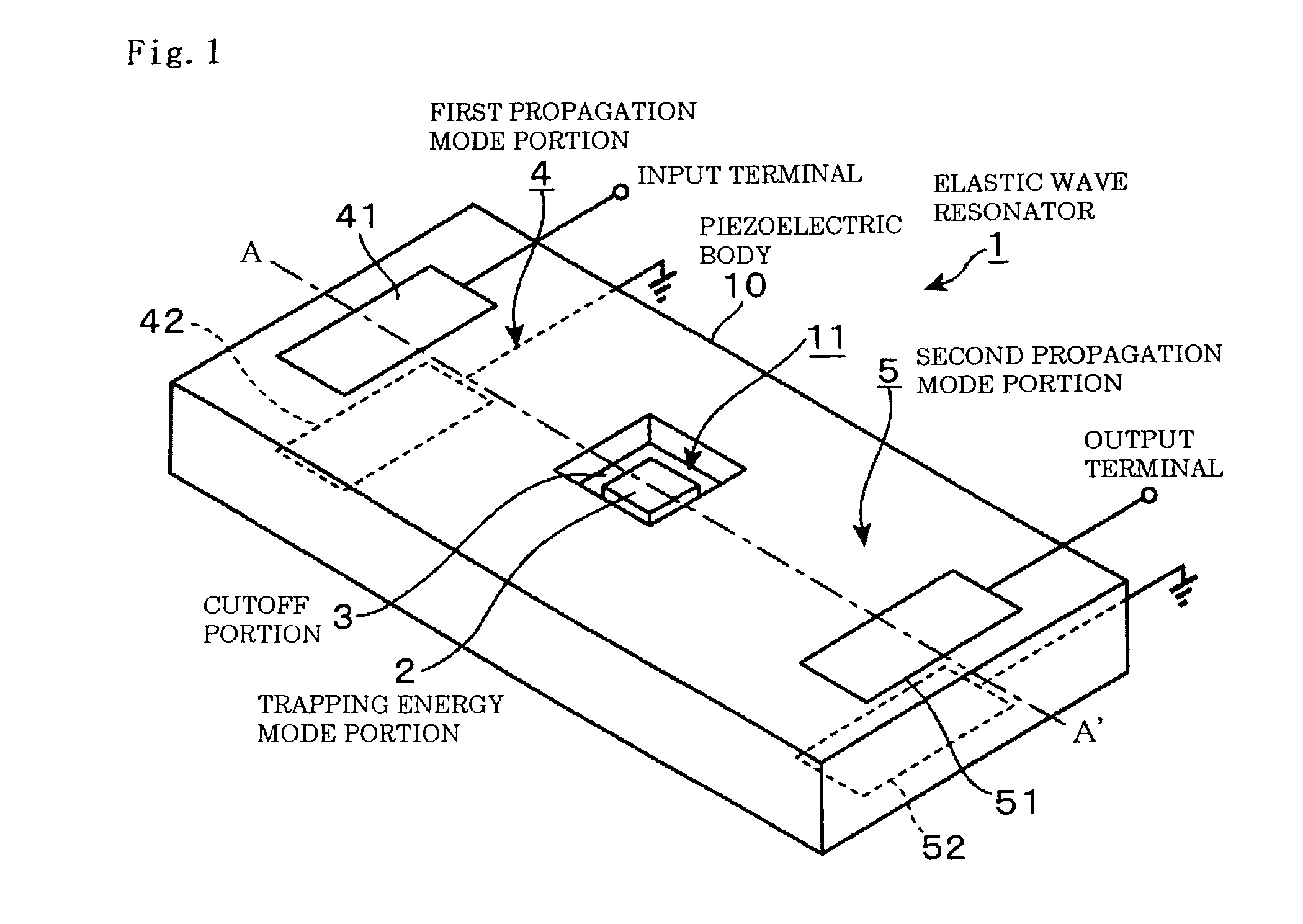

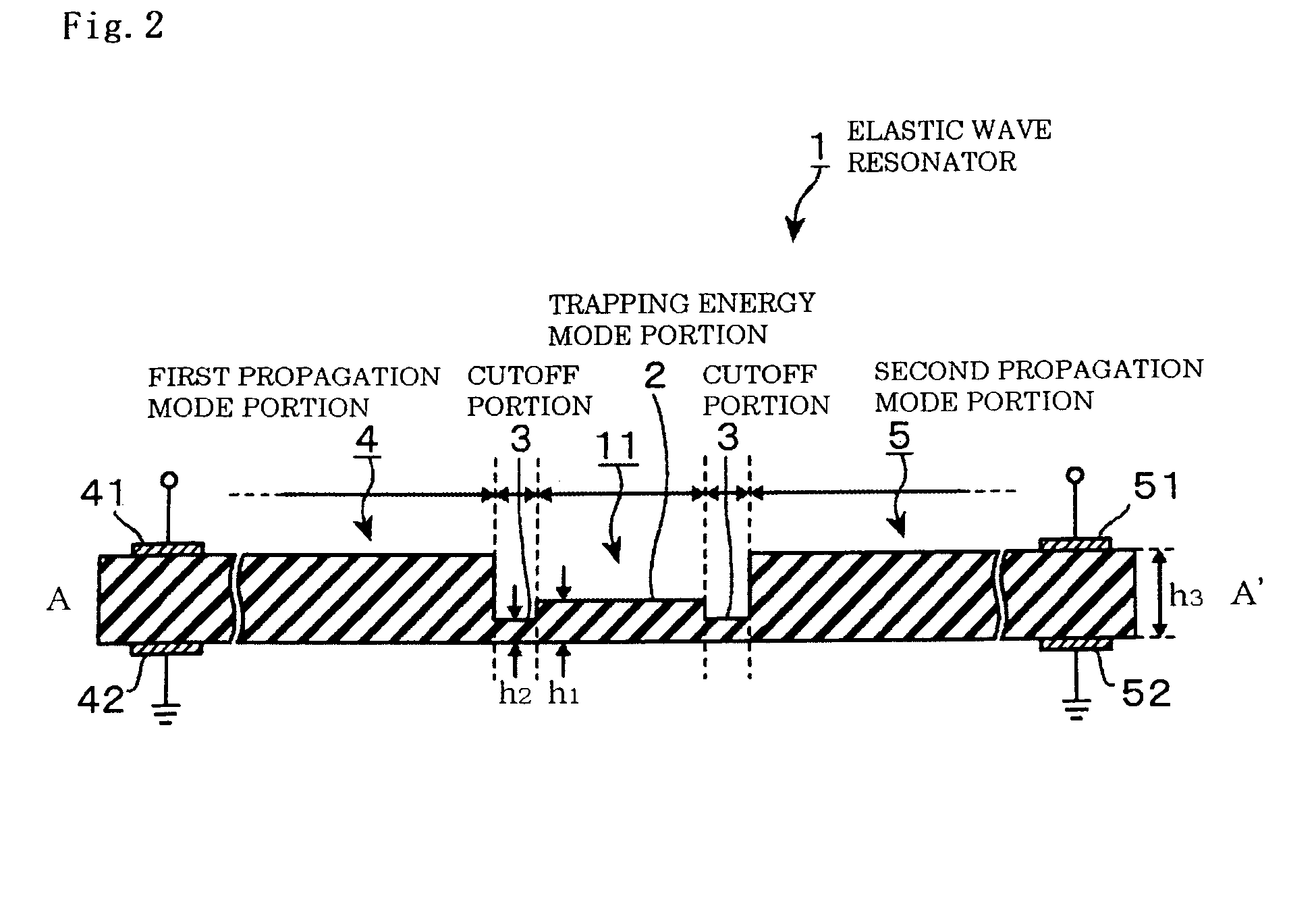

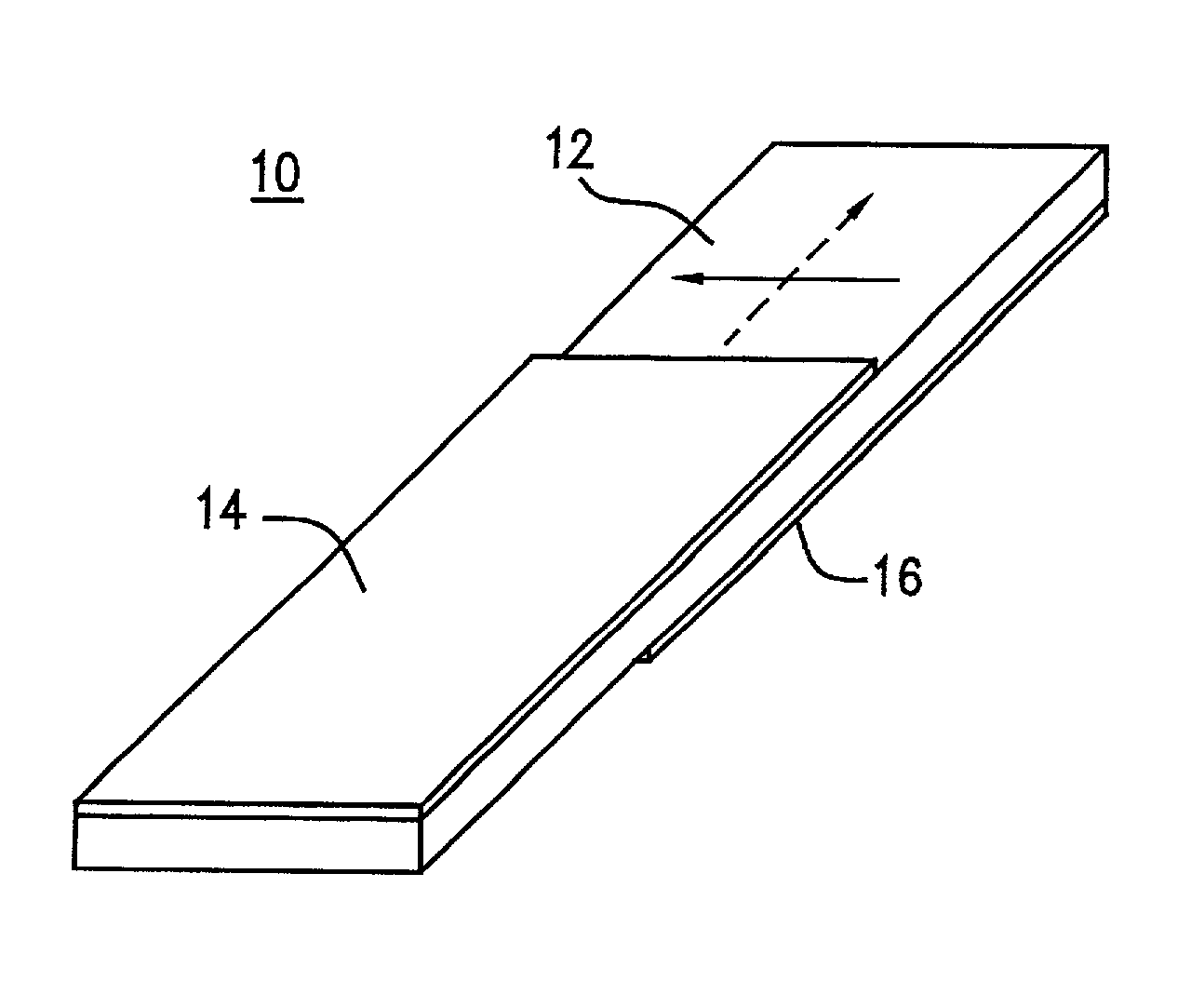

InactiveUS20100164325A1MiniaturizationInhibition effectPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElastomerTrapping

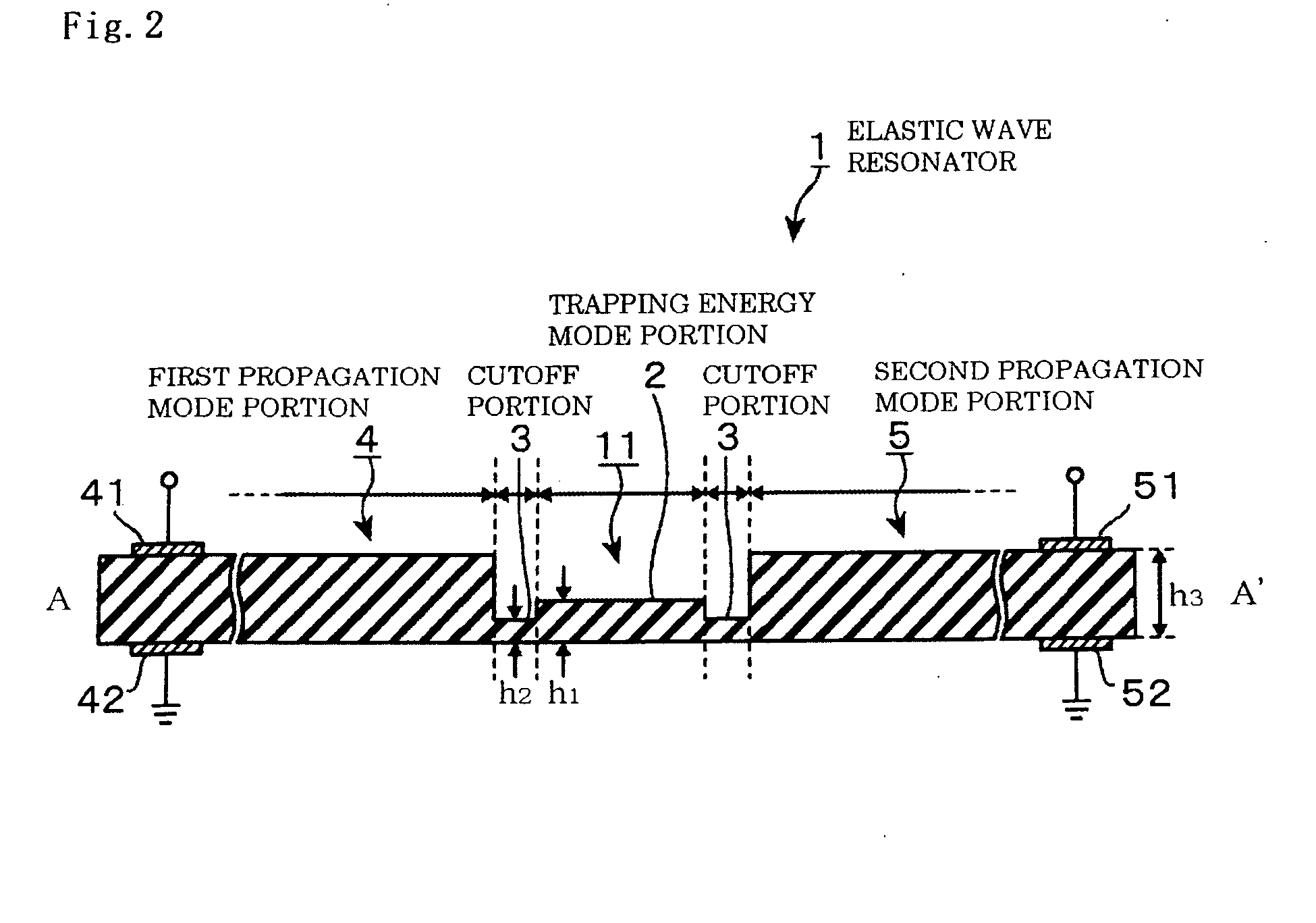

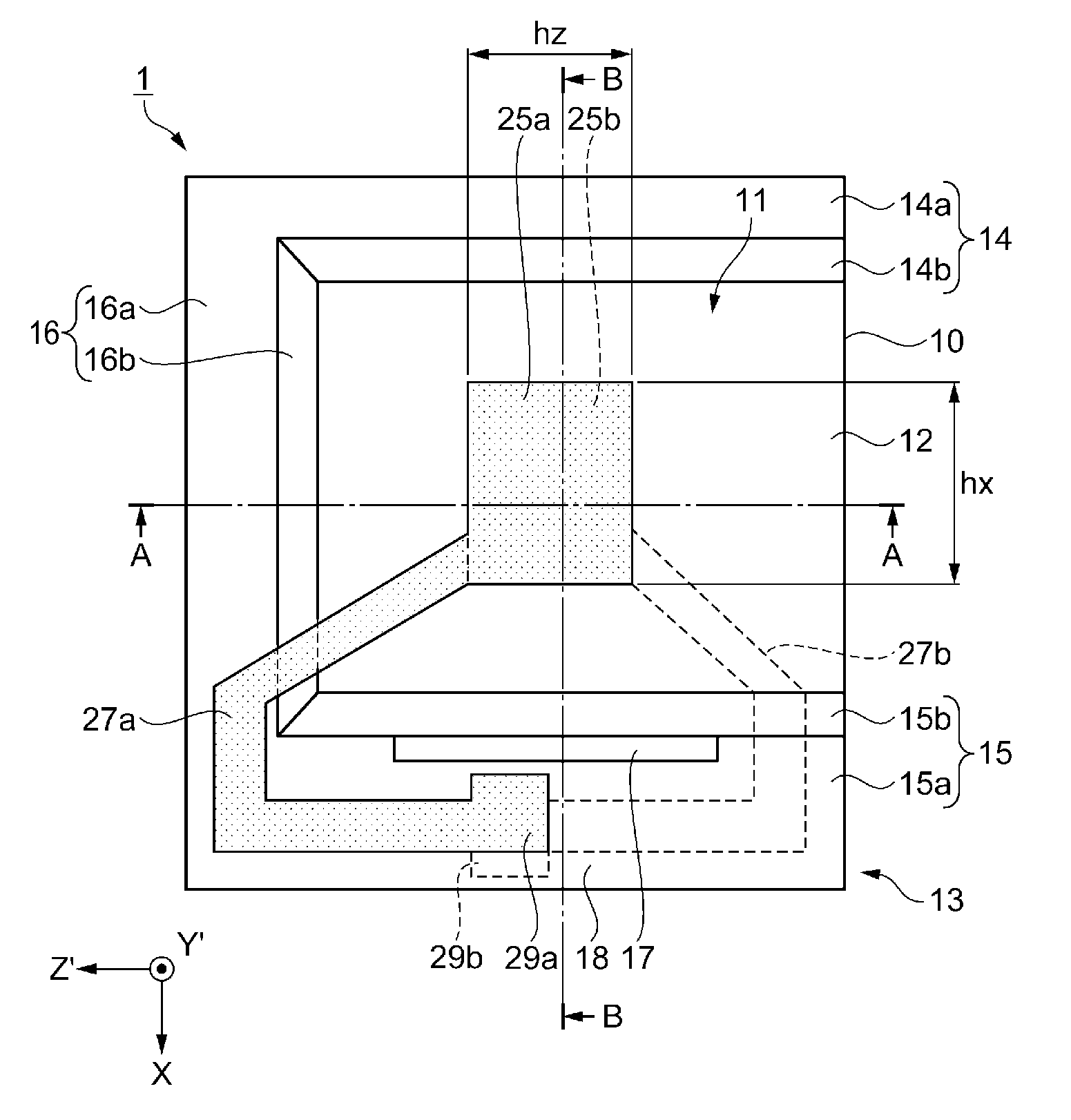

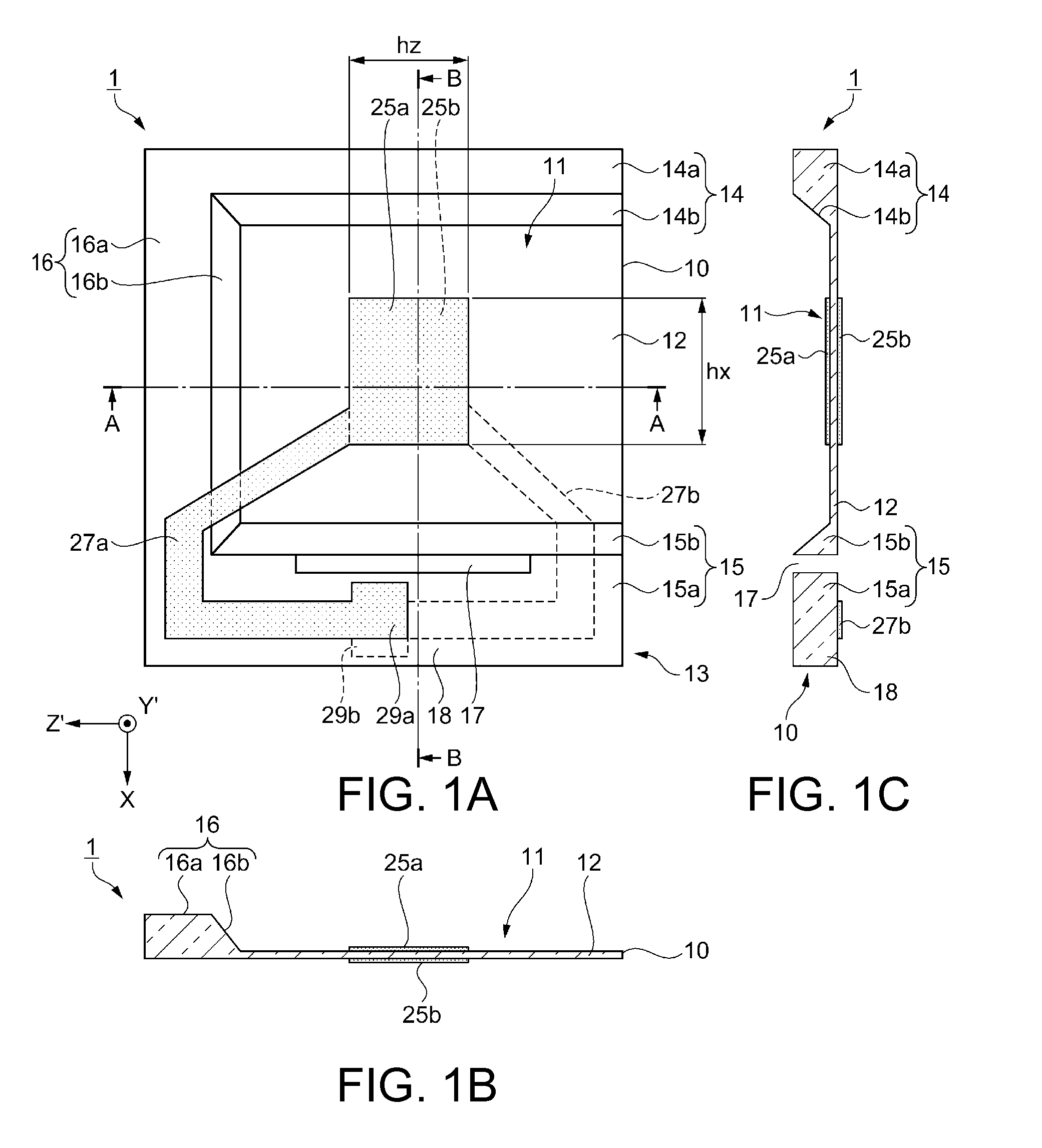

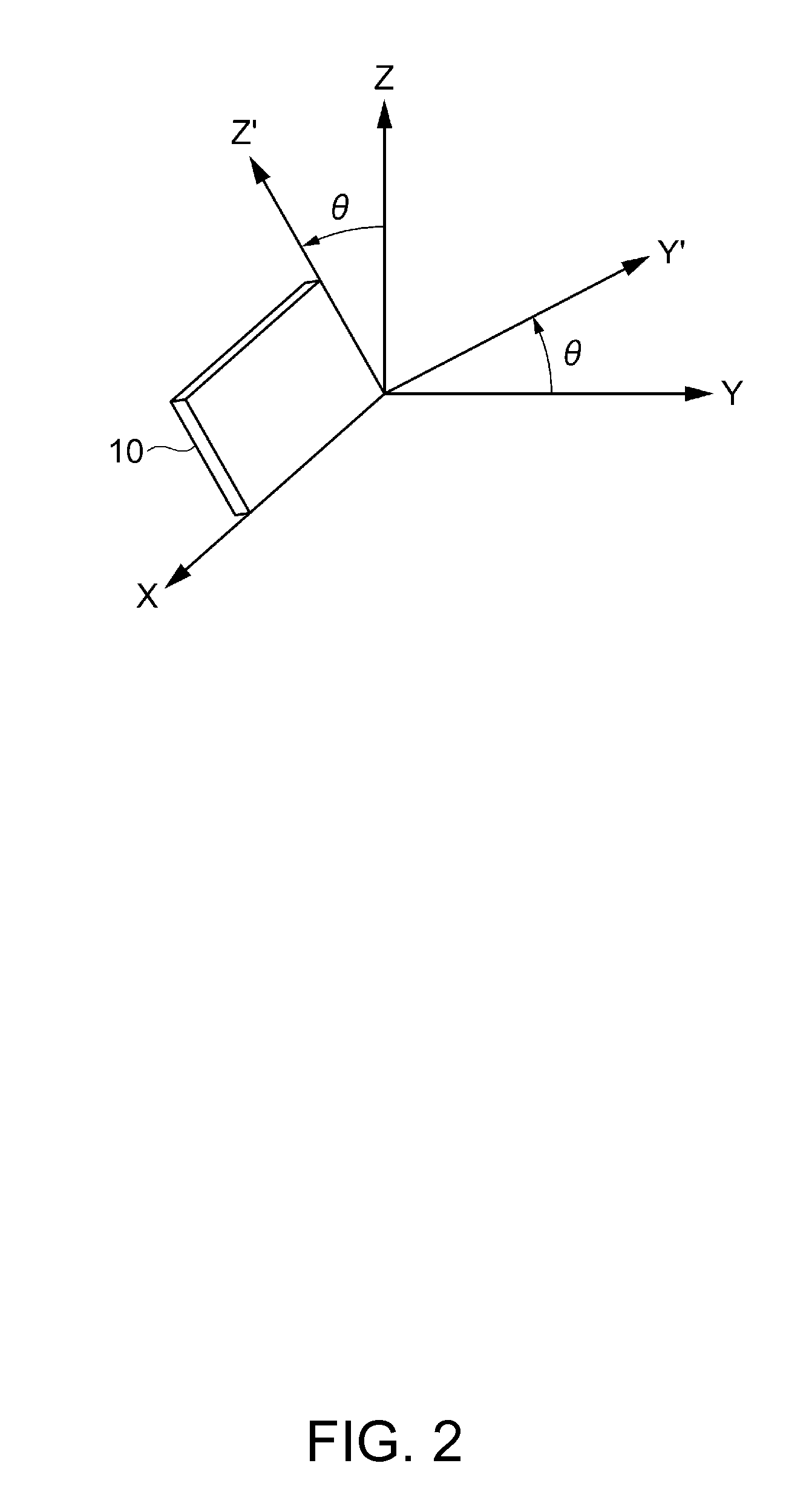

To provide an elastic wave device that is small sized and in which a frequency fluctuation due to a change with time hardly occurs, and an electronic component using the above elastic wave device. A trapping energy mode portion 2 provided in an elastic wave waveguide 10 made of an elastic body material excites a second elastic wave being an elastic wave in an energy trapping mode by a specific frequency component included in a first elastic wave being an elastic wave in a zero-order propagation mode propagated from a first propagation mode portion 4, and a cutoff portion 3 provided in a peripheral region of the trapping energy mode portion 2 has a cutoff frequency being a frequency higher than that of the second elastic wave. A second propagation mode portion mode-converts the second elastic wave leaked through the cutoff portion to a third elastic wave being the elastic wave in the zero-order propagation mode to propagate the third elastic wave.

Owner:NIHON DEMPA KOGYO CO LTD

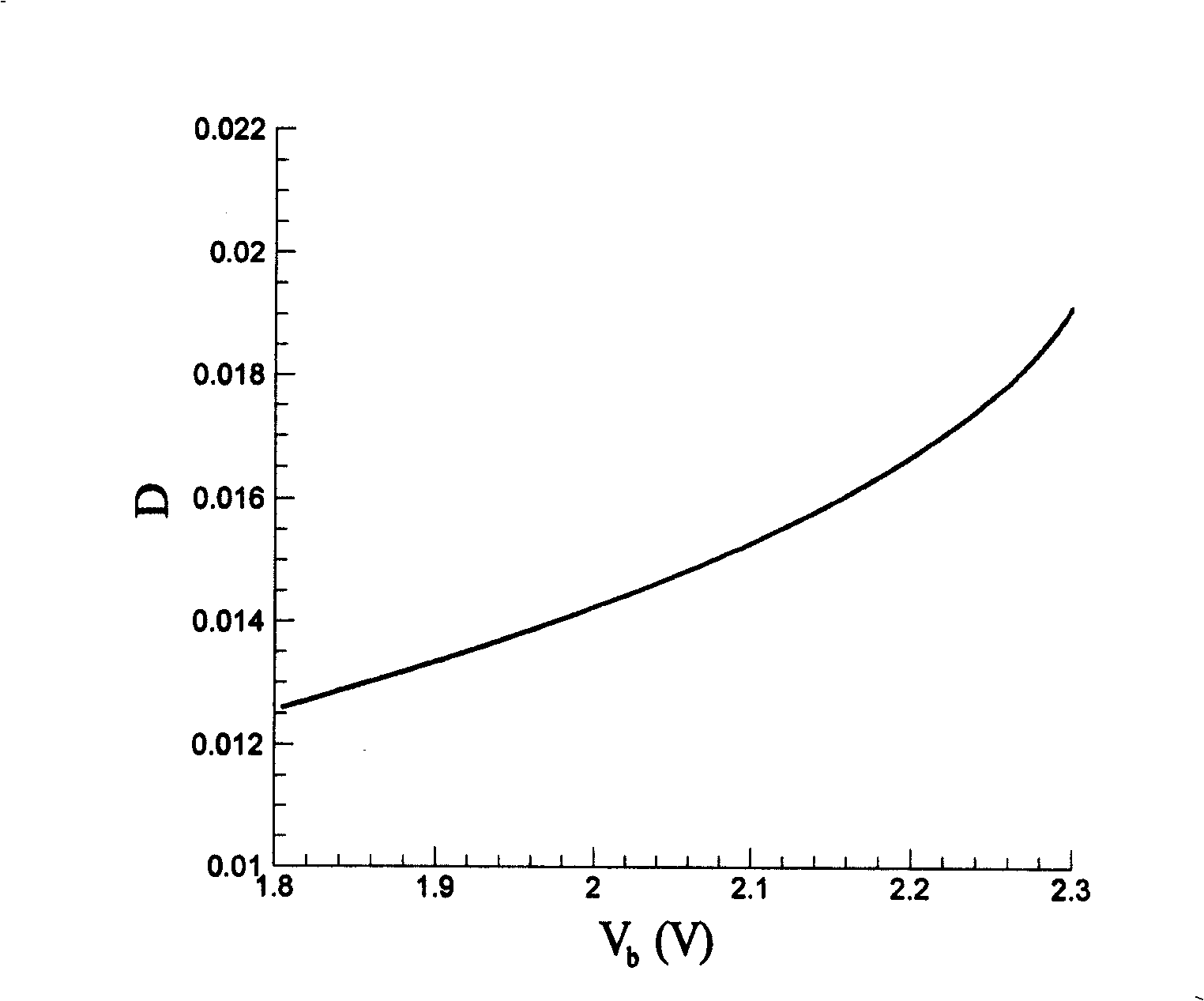

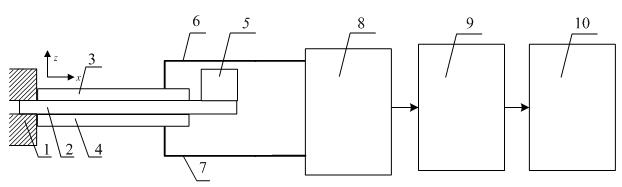

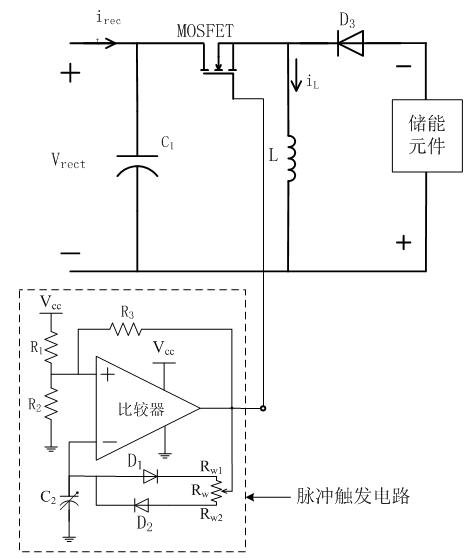

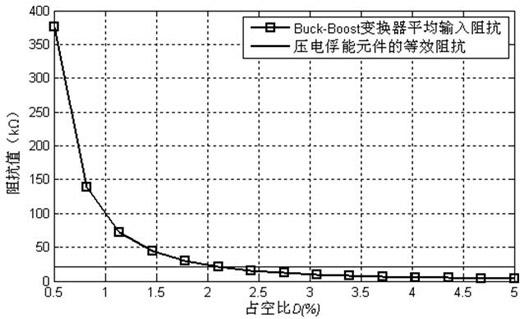

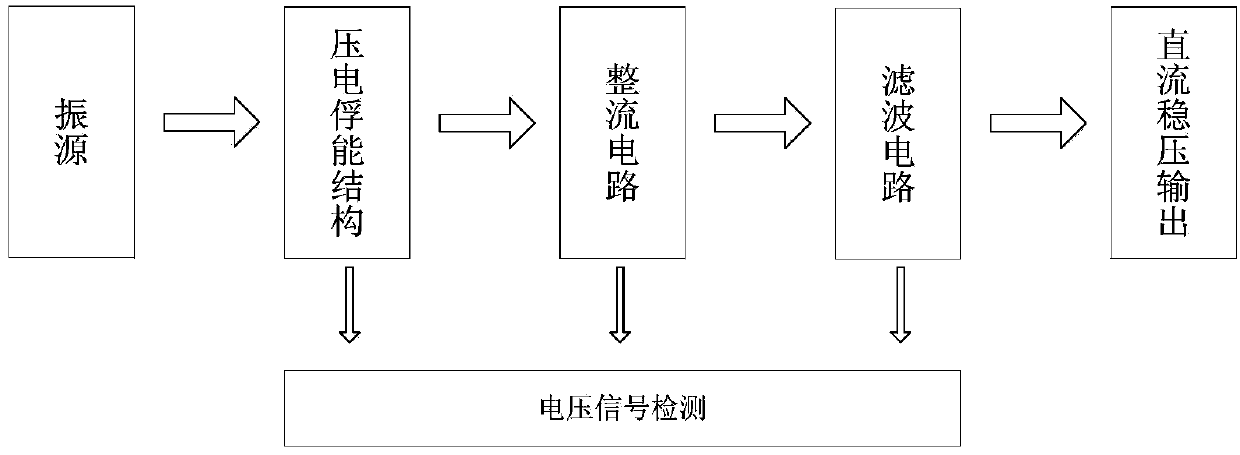

Piezoelectric energy trapping device

InactiveCN102437776AImprove work efficiencyIncrease output powerElectrical storage systemPiezoelectric/electrostriction/magnetostriction machinesMOSFETImpedance matching

The invention relates to an energy trapping device, in particular to a piezoelectric energy trapping device, which comprises a piezoelectric bimorph cantilever, a rectifying circuit, a direct current (DC)-DC regulation circuit, an energy storage element and a conducting wire, wherein an alternating current which is generated by the piezoelectric bimorph cantilever is converted into a DC through the rectifying circuit; and the DC which is obtained by impedance matching of the DC-DC regulation circuit supplies power to a load. By regulating the duty ratio of a metal oxide semiconductor field effect transistor (MOSFET) in the DC-DC regulation circuit, the average input resistance of a DC converter can be regulated, so that the impedance matching of piezoelectric energy trapping elements is realized, and the output power of the piezoelectric energy trapping device is improved.

Owner:SOUTHEAST UNIV

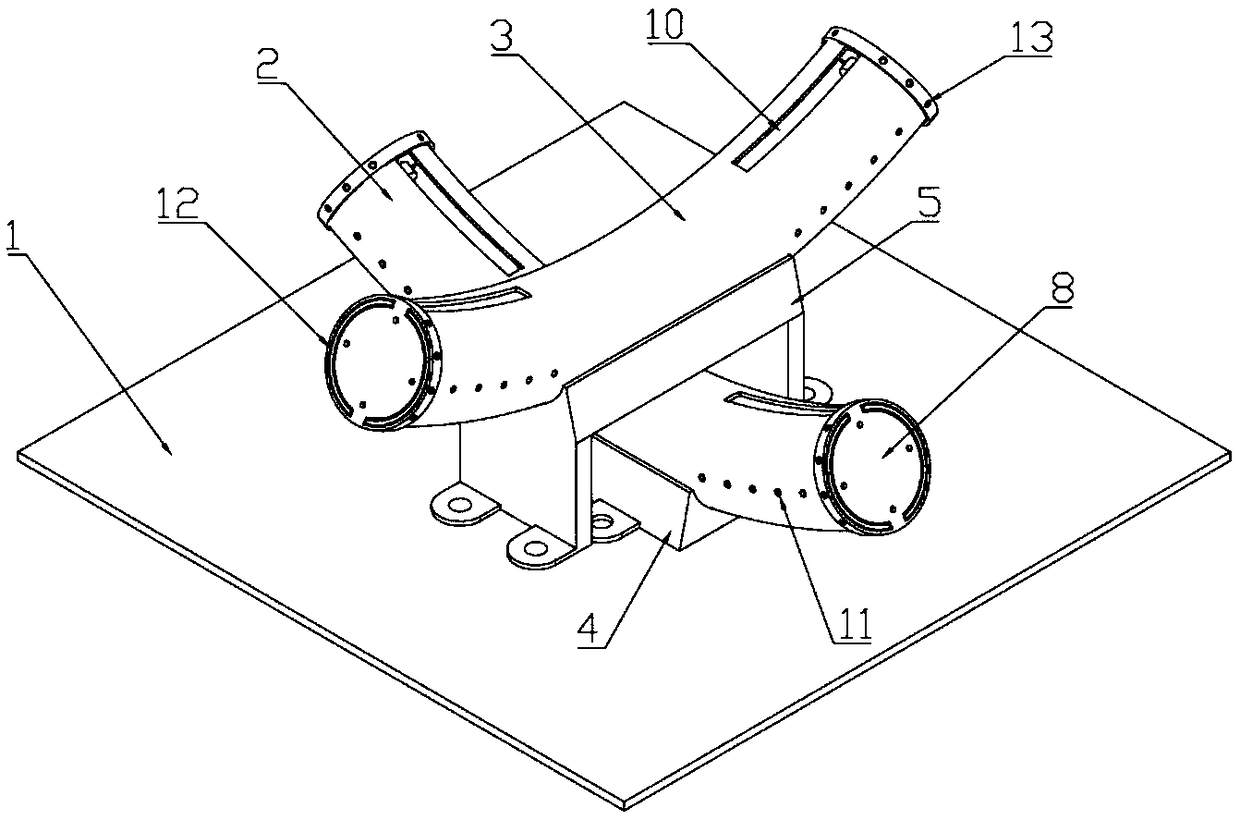

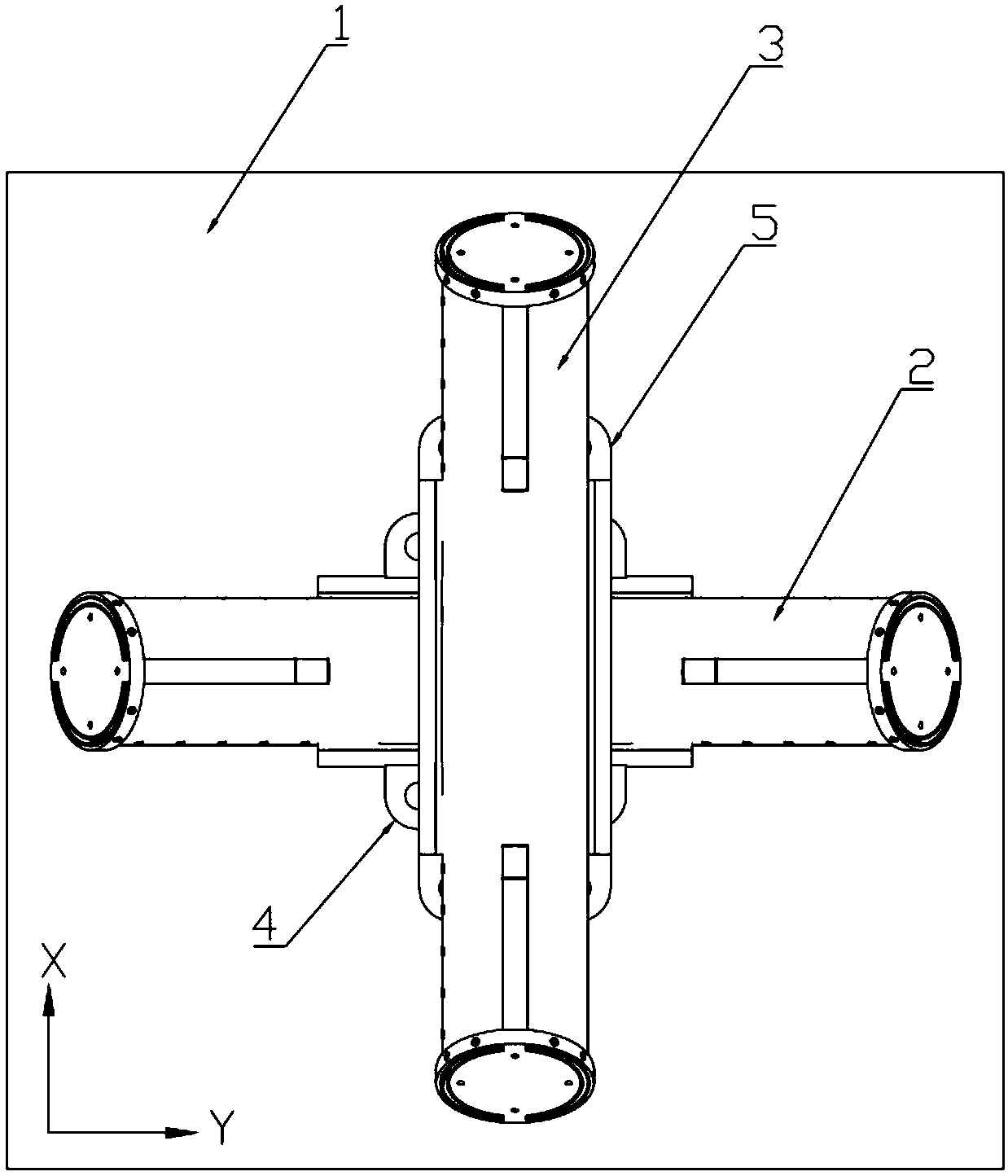

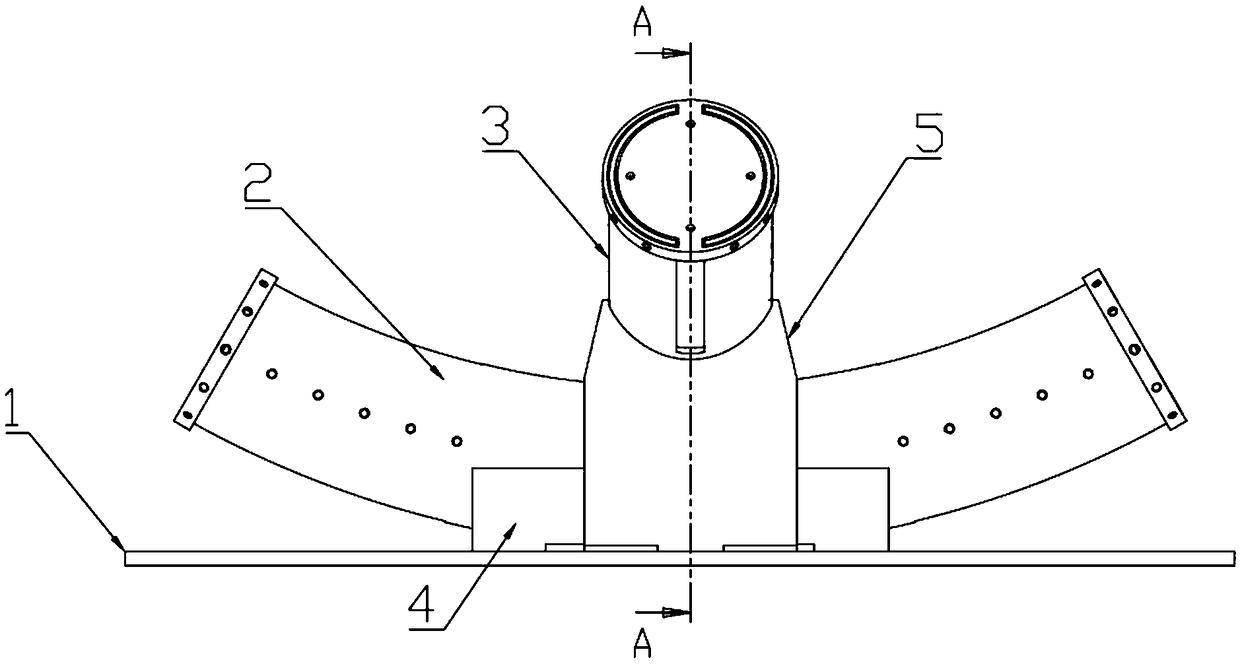

Composite nonlinear energy trapping vibration damper

PendingCN108895114AMeeting complex vibration damping requirementsAchieving Secondary DissipationNon-rotating vibration suppressionMagnetic springsViscous dampingElectrical conductor

The invention discloses a composite nonlinear energy trapping vibration damper. Two nonlinear tracks of the composite nonlinear energy trapping vibration damper are separately crossed in the X direction and the Y direction. A tubular track in the X direction is arranged on a bottom layer, and a tubular track in the Y direction is arranged on an upper layer. When two balls separately roll in respective pipes, reactive force which is compounded theoretically can point to an optional direction in a three-dimensional space, and complicated vibration damping requirements for the vibration damper inwork can be met. Stopping covers which are fixedly provided with high-damping rubber are separately mounted at two ends of each track, and thus, energy dissipation during impacting is enhanced. In addition, a permanent magnet is embedded in the balls, and when the balls roll in the pipes, a movable magnetic field can be formed. When the movable magnetic field is intersected with the metal pipes,mutual cutting of a magnetic induction line and a conductor is caused, thus, eddy current is generated in the metal pipes, electromagnetic force generated by the eddy current can be equivalent to a viscous damping, and thus, energy is dissipated by an electromagnetic effect.

Owner:HUAZHONG UNIV OF SCI & TECH +1

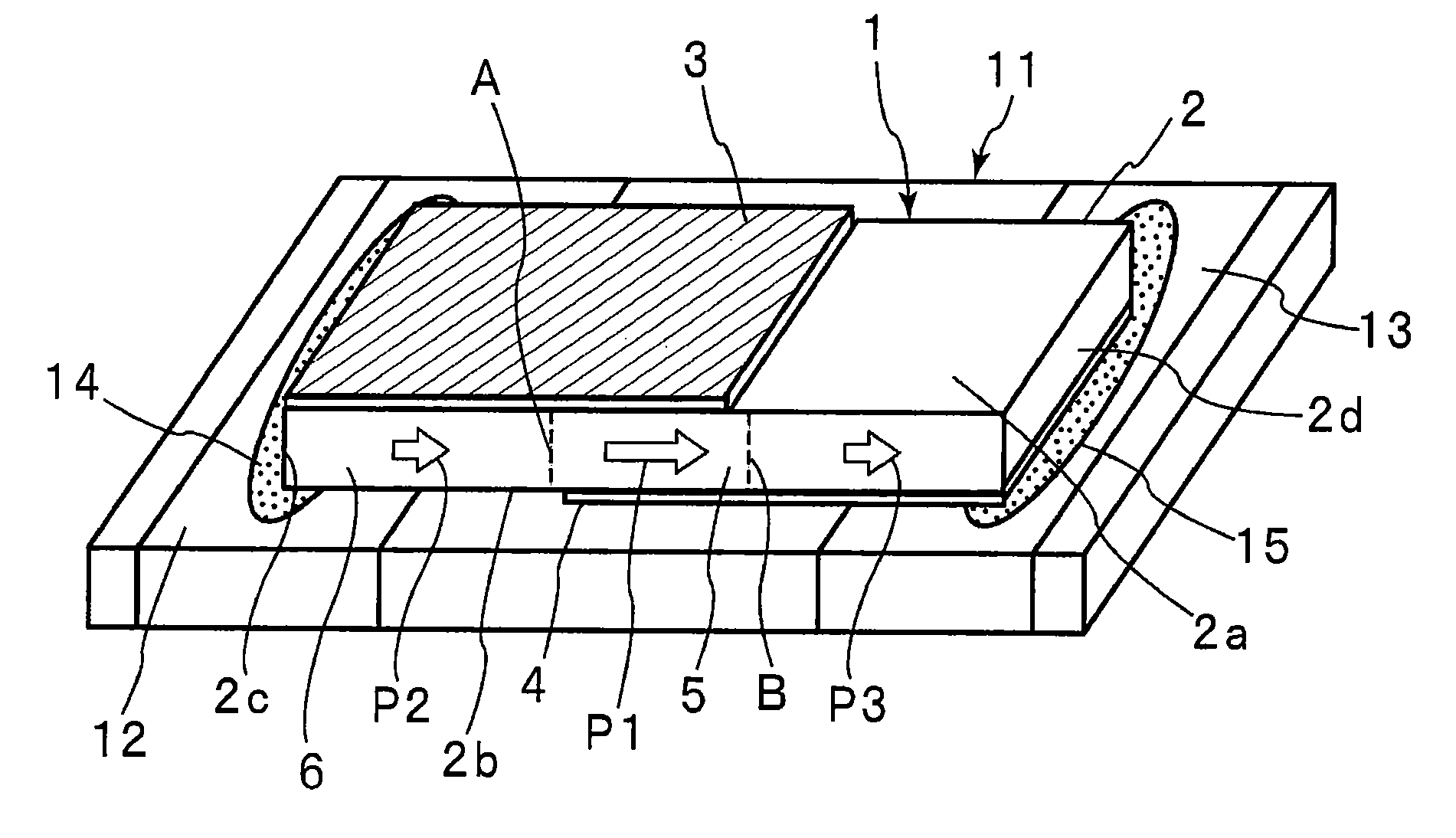

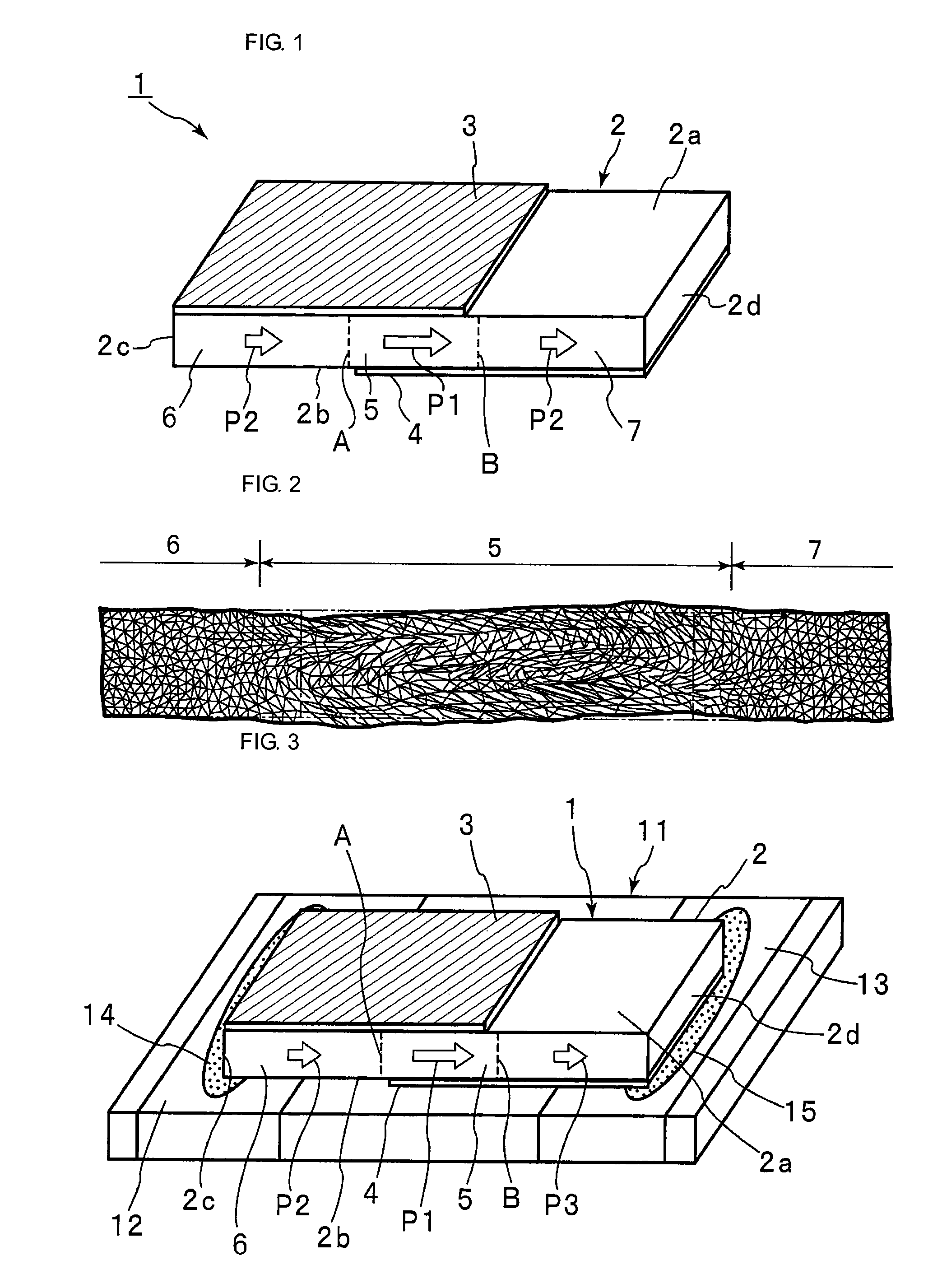

Elastic wave device and electronic component

InactiveUS8242664B2Inhibition effectExclude influencePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTrappingElectronic component

To provide an elastic wave device that is small sized and in which a frequency fluctuation due to a change with time hardly occurs, and an electronic component using the above elastic wave device. A trapping energy mode portion 2 provided in an elastic wave waveguide 10 made of an elastic body material excites a second elastic wave being an elastic wave in an energy trapping mode by a specific frequency component included in a first elastic wave being an elastic wave in a zero-order propagation mode propagated from a first propagation mode portion 4, and a cutoff portion 3 provided in a peripheral region of the trapping energy mode portion 2 has a cutoff frequency being a frequency higher than that of the second elastic wave. A second propagation mode portion mode-converts the second elastic wave leaked through the cutoff portion to a third elastic wave being the elastic wave in the zero-order propagation mode to propagate the third elastic wave.

Owner:NIHON DEMPA KOGYO CO LTD

Elastic wave device and electronic component

InactiveUS20100171390A1MiniaturizationInhibition effectPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElastomerTrapping

To provide an elastic wave device that is small sized and in which a frequency fluctuation due to a change with time hardly occurs, and an electronic component using the above elastic wave device. A trapping energy mode portion 2 provided in an elastic wave waveguide 10 made of an elastic body material excites a second elastic wave being an elastic wave in an energy trapping mode by a specific frequency component included in a first elastic wave being an elastic wave in a first or higher-order propagation mode propagated from a first propagation mode portion 4, and a cutoff portion 3 provided in a peripheral region of the trapping energy mode portion 2 has a cutoff frequency being a frequency higher than that of the second elastic wave. A second propagation mode portion mode-converts the second elastic wave leaked through the cutoff portion to a third elastic wave being the elastic wave in the propagation mode to propagate the third elastic wave.

Owner:NIHON DEMPA KOGYO CO LTD

Resonator element, resonator, electronic device, electronic apparatus, and moving object

ActiveUS20150115772A1Reduce the valueReduce thicknessImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectronThickness shear

A resonator element includes a vibrating portion that vibrates in a thickness shear vibration and includes a first main surface and a second main surface which are in a front and back relationship to each other, a first excitation electrode that is provided on the first main surface, and a second excitation electrode that is provided on the second main surface, and an energy trapping coefficient M satisfies a relationship of 33.6≦M≦65.1.

Owner:SEIKO EPSON CORP

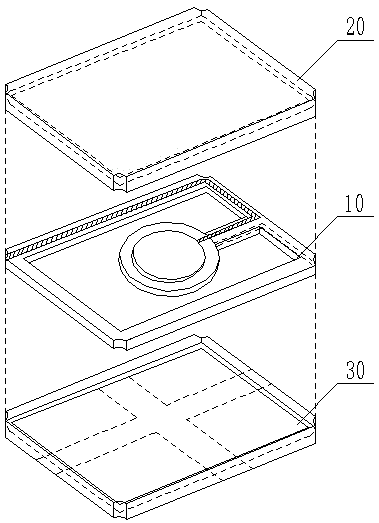

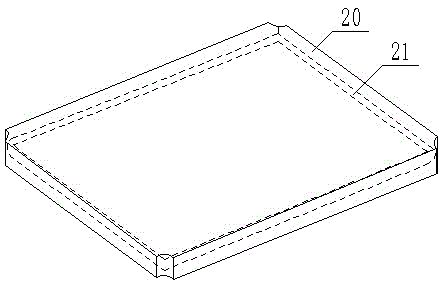

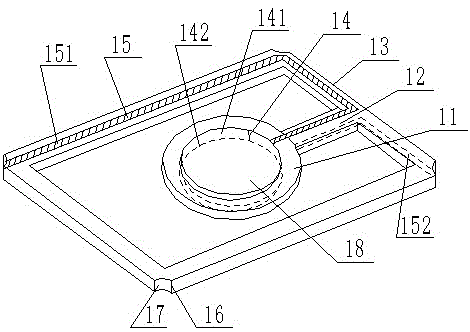

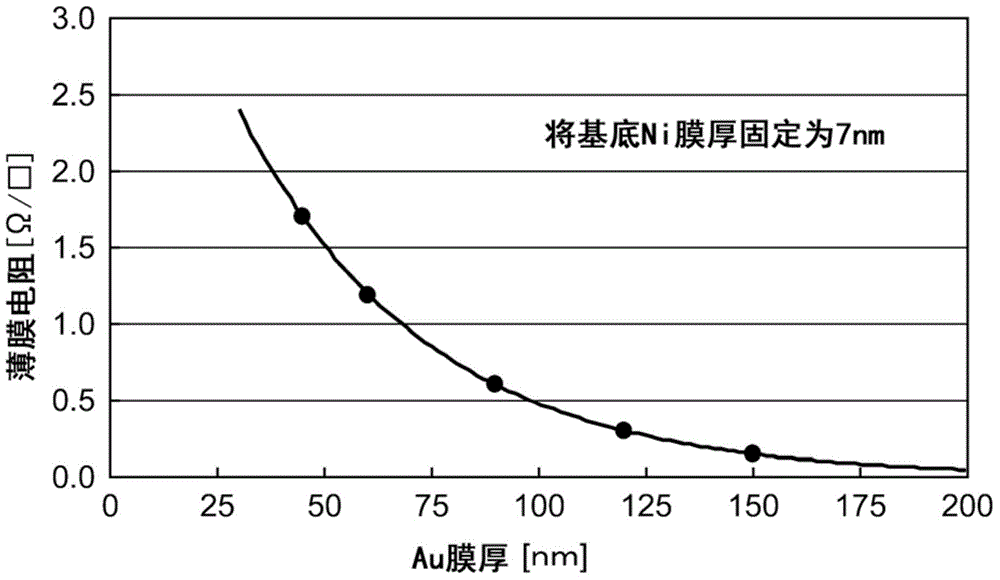

Quartz crystal resonator with circular wafer structure and manufacture method thereof

InactiveCN105634436AReduced chance of parasitic vibrationImprove performanceImpedence networksQuartz crystal resonatorEngineering

The present invention relates to a quartz crystal resonator with a circular wafer structure. The quartz crystal resonator is packaged by a quartz wafer (10), a packaging cover (20) and a packaging base (30). The quartz wafer (10) includes a circular member (11), a connecting part (12) and a protection frame (13). The circular member (11) can oscillate freely in a packaged cavity and is provided with an electrode area (14). The connecting part (12) and the protection frame (13) are provided with a metal layer A (15). A positioning hole (16) in the protection frame (13) is internally provided with a metal layer B (17). The packaging base (30) is provided with a pin (31). The electrode area (14) is electrically connected with the pin (31) by using the metal layer A (15) and the metal layer B (17). The present invention also discloses a manufacture method of the quartz crystal resonator with the circular wafer structure. The manufacture method can be used for mass production of small resonators at low cost, and can enhance center energy trapping effect of the quartz wafer and improve product consistency remarkably.

Owner:CHENGDU TIMEMAKER CRYSTAL TECH

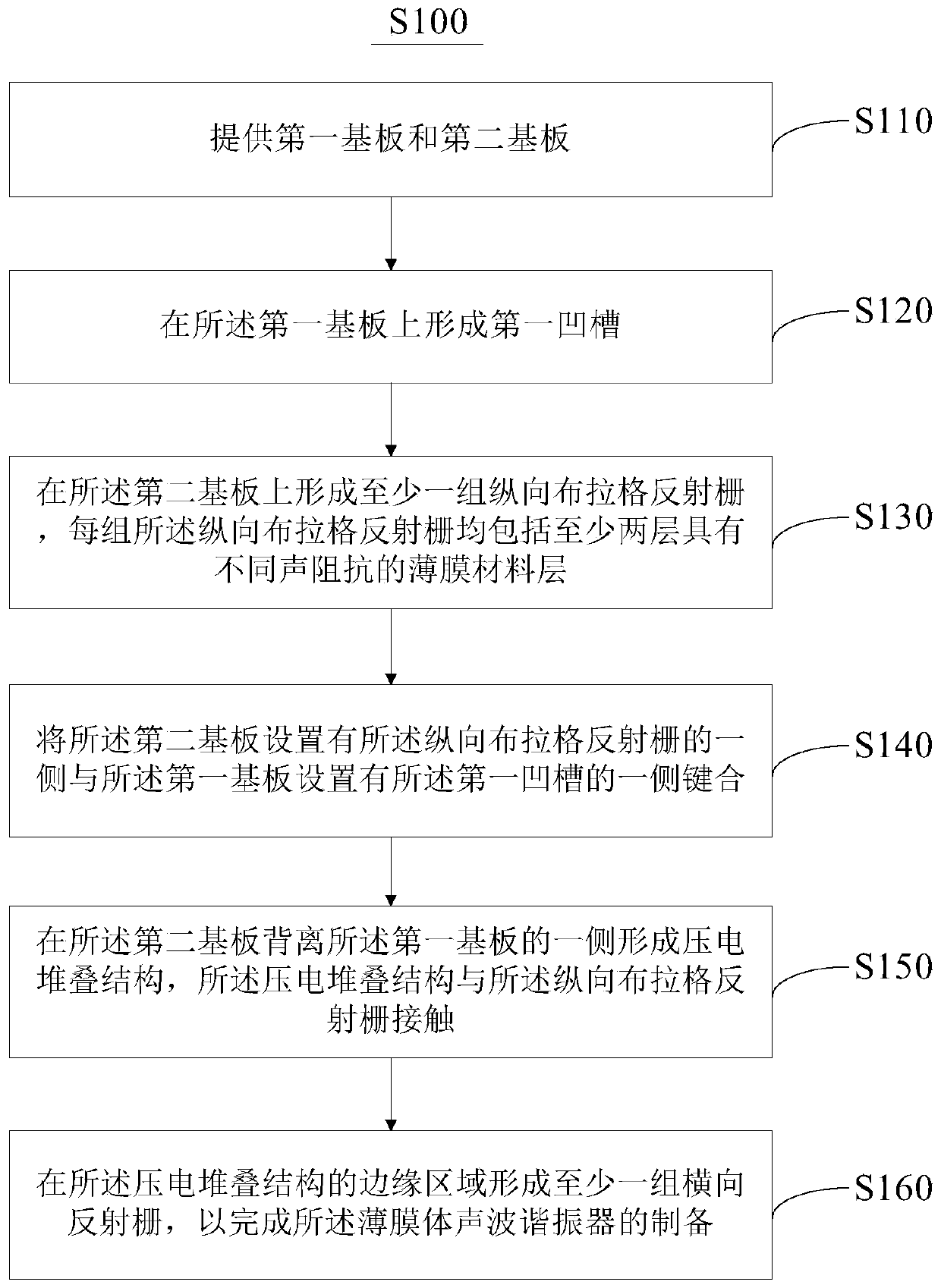

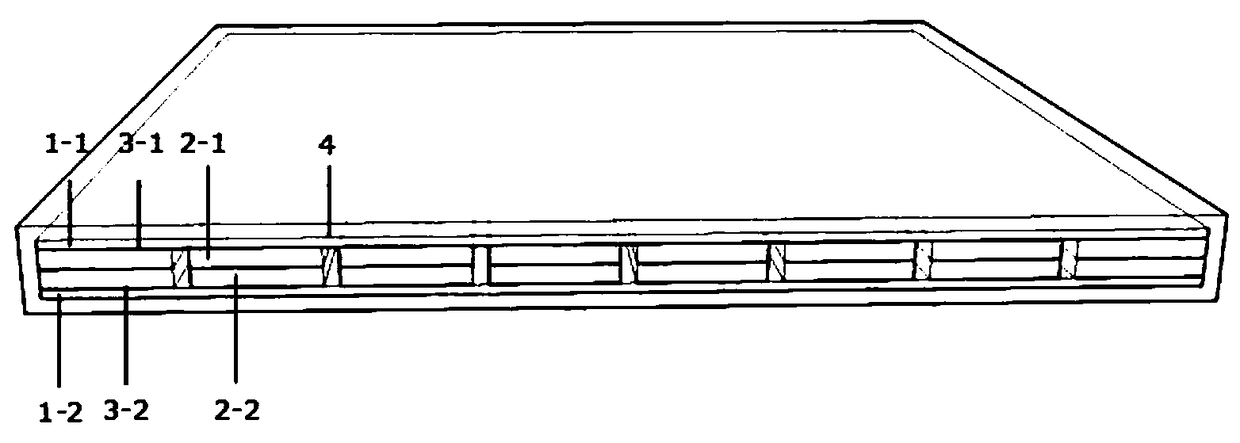

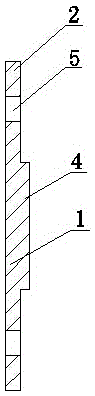

Film bulk acoustic resonator and preparation method thereof

PendingCN110311643AImprove frequency stabilityReduce lossImpedence networksThin-film bulk acoustic resonatorGrating

The invention provides a film bulk acoustic resonator and a preparation method thereof. The preparation method comprises the following steps: providing a first substrate and a second substrate; forming a first groove in the first substrate; forming at least one group of longitudinal Bragg reflection gratings on the second substrate, wherein each group of longitudinal Bragg reflection gratings comprises at least two thin film material layers with different acoustic impedances; bonding the side, provided with the longitudinal Bragg reflection grating, of the second substrate with the side, provided with the first groove, of the first substrate; forming a piezoelectric stacking structure on one side, deviating from the first substrate, of the second substrate; and forming at least one group of transverse reflection grids in the edge area of the piezoelectric stack structure to complete the preparation of the film bulk acoustic wave resonator. The prepared film bulk acoustic resonator is provided with reflecting gates in the transverse direction and the longitudinal direction, acoustic energy can be limited in an effective area of a device, the energy trapping effect can be achieved, the Q value of the device can be further improved, and therefore the resonator has high frequency stability.

Owner:HANGZHOU SAPPLAND MICROELECTRONICS TECH CO LTD

Resonator element, resonator, electronic device, electronic apparatus, and moving object

InactiveCN104601139AImprove frequency stabilityGood S/N ratioImpedence networksElectronThickness shear

A resonator element includes a vibrating portion that vibrates in a thickness shear vibration and includes a first main surface and a second main surface which are in a front and back relationship to each other, a first excitation electrode that is provided on the first main surface, and a second excitation electrode that is provided on the second main surface, and an energy trapping coefficient M satisfies a relationship of 33.6≰M≰65.1.

Owner:SEIKO EPSON CORP

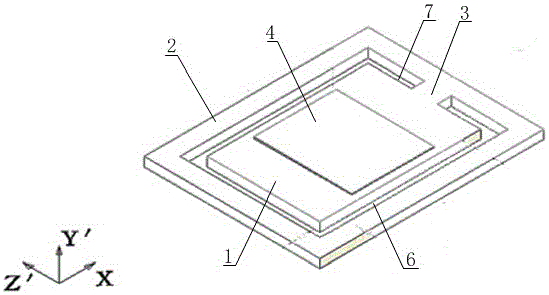

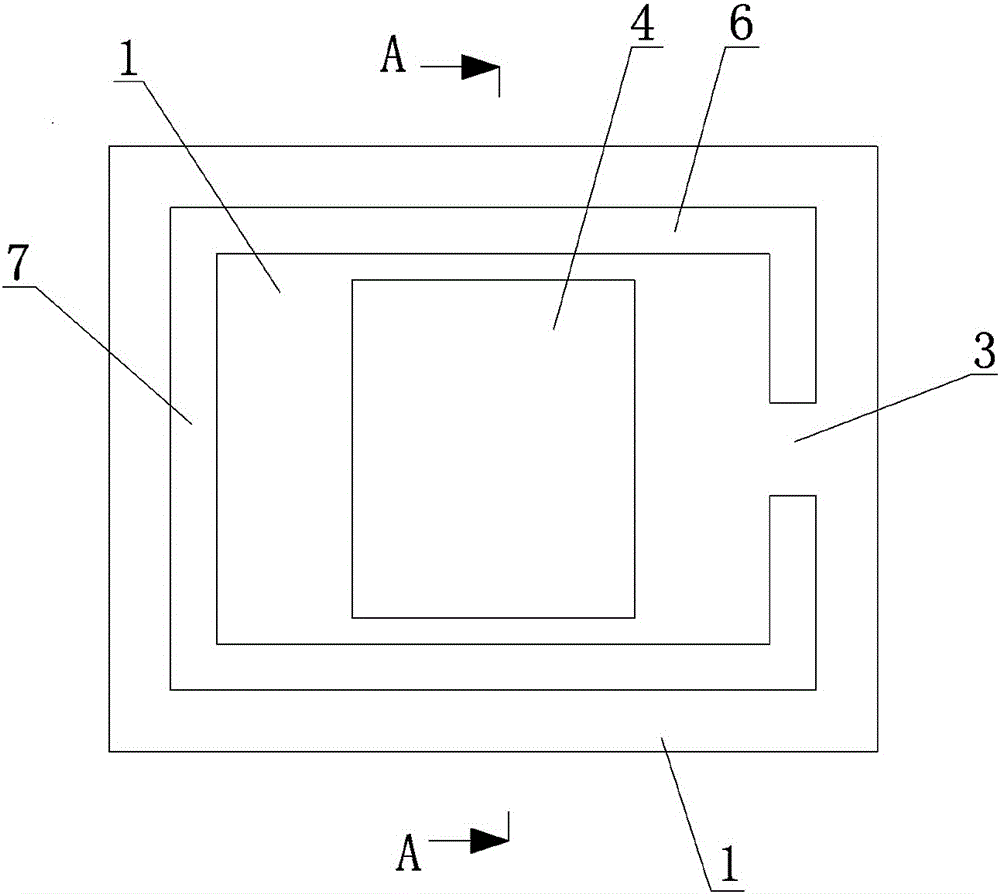

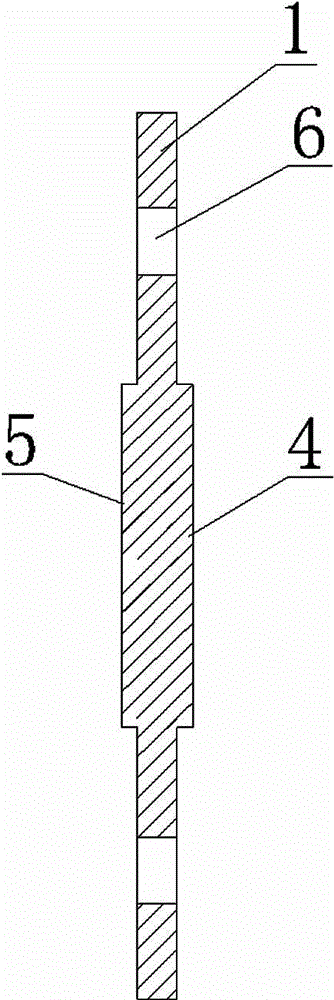

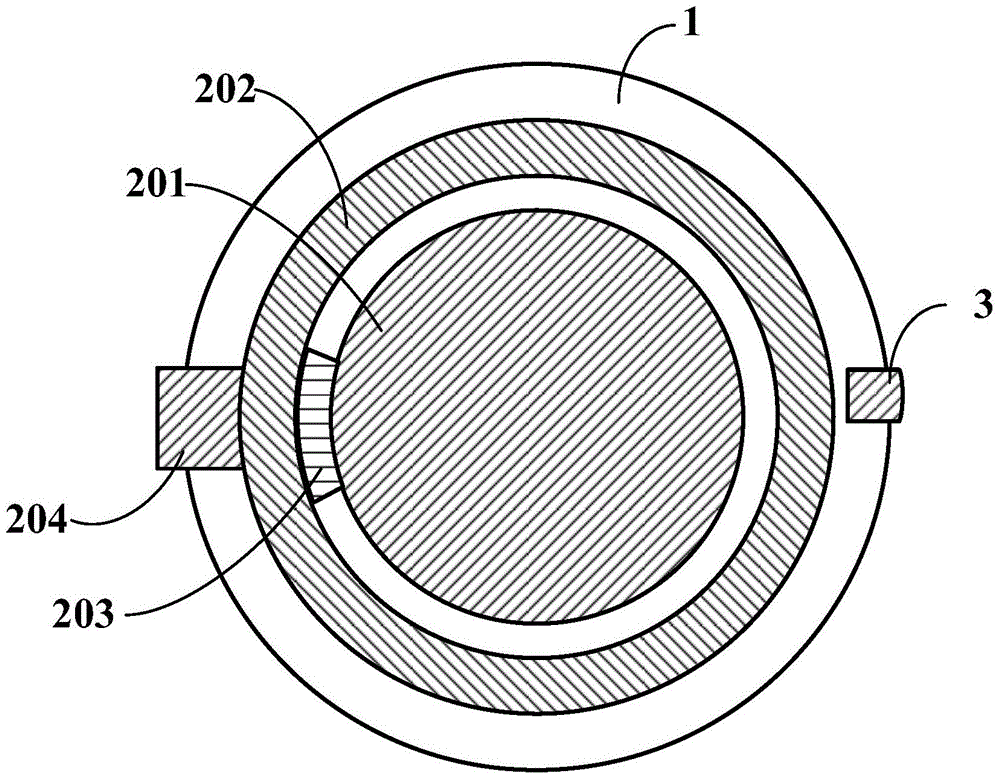

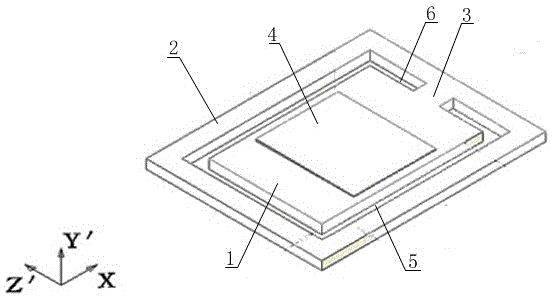

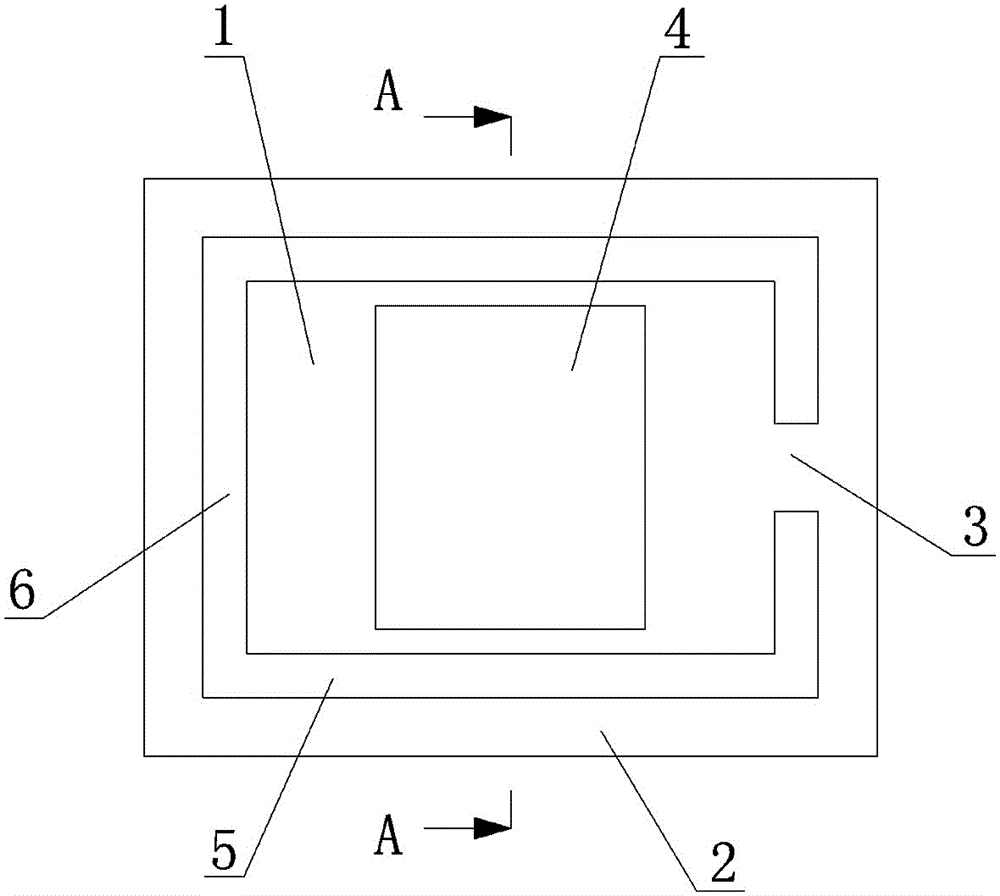

Novel piezoelectric quartz wafer with dual-convex structure and machining process thereof

InactiveCN104993797AImprove protectionEnhanced trapping effectImpedence networksConvex structureWafering

The invention discloses a novel piezoelectric quartz wafer with a dual-convex structure. The novel piezoelectric quartz wafer comprises a central member (1), a protection frame (2) and connection parts (3), wherein a die cavity is formed in the protection frame (2); the top surface of the central member (1) is provided with a boss I (4); the bottom surface of the central member (1) is provided with a boss II (5); straight slots A (6) are formed between the two long edges of the protection frame (2) and the two long edges of the central member (1); straight slots B (7) are formed between the two short edges of the protection frame (2) and the two short edges of the central member (1); the straight slots A (6) are communicated with the straight slots B (7); and the connection parts (3) are arranged in any straight slot B (7). The invention has the beneficial effects that small-sized quartz wafers can be produced in batches; parasitic vibration generated on edges is weakened; the energy trapping effect in the center of the quartz wafer can be enhanced; the machining accuracy is increased; and the consistence of a product is improved greatly.

Owner:CHENGDU TIMEMAKER CRYSTAL TECH

Elastic wave device and electronic component

InactiveUS8237329B2Inhibition effectExclude influencePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElastomerTrapping

To provide an elastic wave device that is small sized and in which a frequency fluctuation due to a change with time hardly occurs, and an electronic component using the above elastic wave device. A trapping energy mode portion 2 provided in an elastic wave waveguide 10 made of an elastic body material excites a second elastic wave being an elastic wave in an energy trapping mode by a specific frequency component included in a first elastic wave being an elastic wave in a first or higher-order propagation mode propagated from a first propagation mode portion 4, and a cutoff portion 3 provided in a peripheral region of the trapping energy mode portion 2 has a cutoff frequency being a frequency higher than that of the second elastic wave. A second propagation mode portion mode-converts the second elastic wave leaked through the cutoff portion to a third elastic wave being the elastic wave in the propagation mode to propagate the third elastic wave.

Owner:NIHON DEMPA KOGYO CO LTD

Piezoelectric device

InactiveUS20020125796A1Little high-frequency lossHigh temperature resistanceImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectricityTemperature resistance

A piezoelectric device having an electromechanical coefficient, which can be applied to practical uses, is obtained by an energy-trapping effect using a piezoelectric ceramic having a layered perovskite structure provided with high-temperature resistance and little high-frequency loss. The piezoelectric device has a substrate formed of a piezoelectric ceramic having a layered perovskite structure. The c-axis in the substrate is preferentially oriented in the width direction thereof, and the substrate is polarized in the longitudinal direction. Two electrodes are formed on both main surfaces of the substrate so as to oppose each other in the vicinity of the central part thereof. As a material used for the substrate, a piezoelectric ceramic composition primarily composed of a ceramic composition represented by the general formula CaBi.sub.4Ti.sub.4O.sub.15 is preferably used.

Owner:MURATA MFG CO LTD

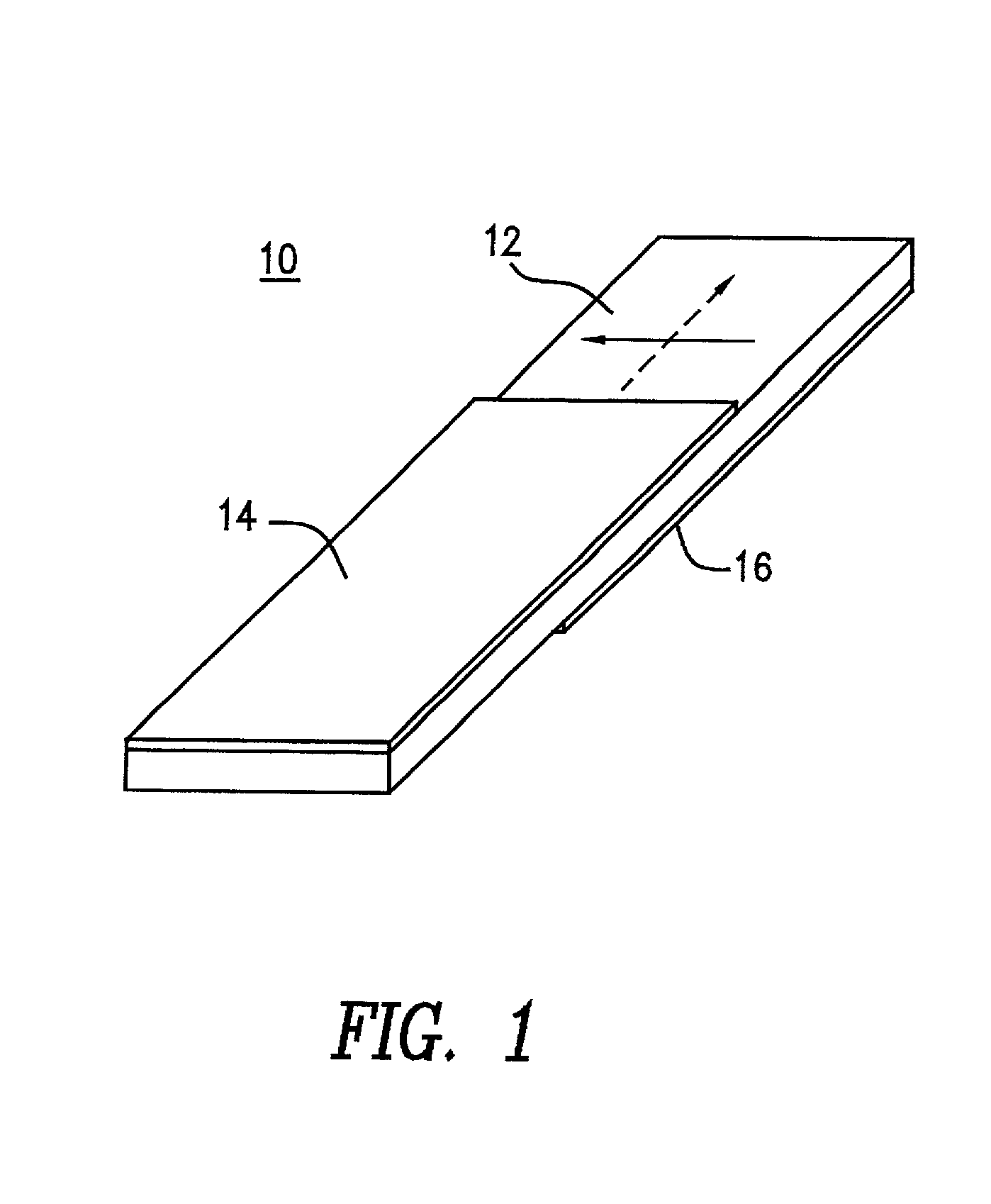

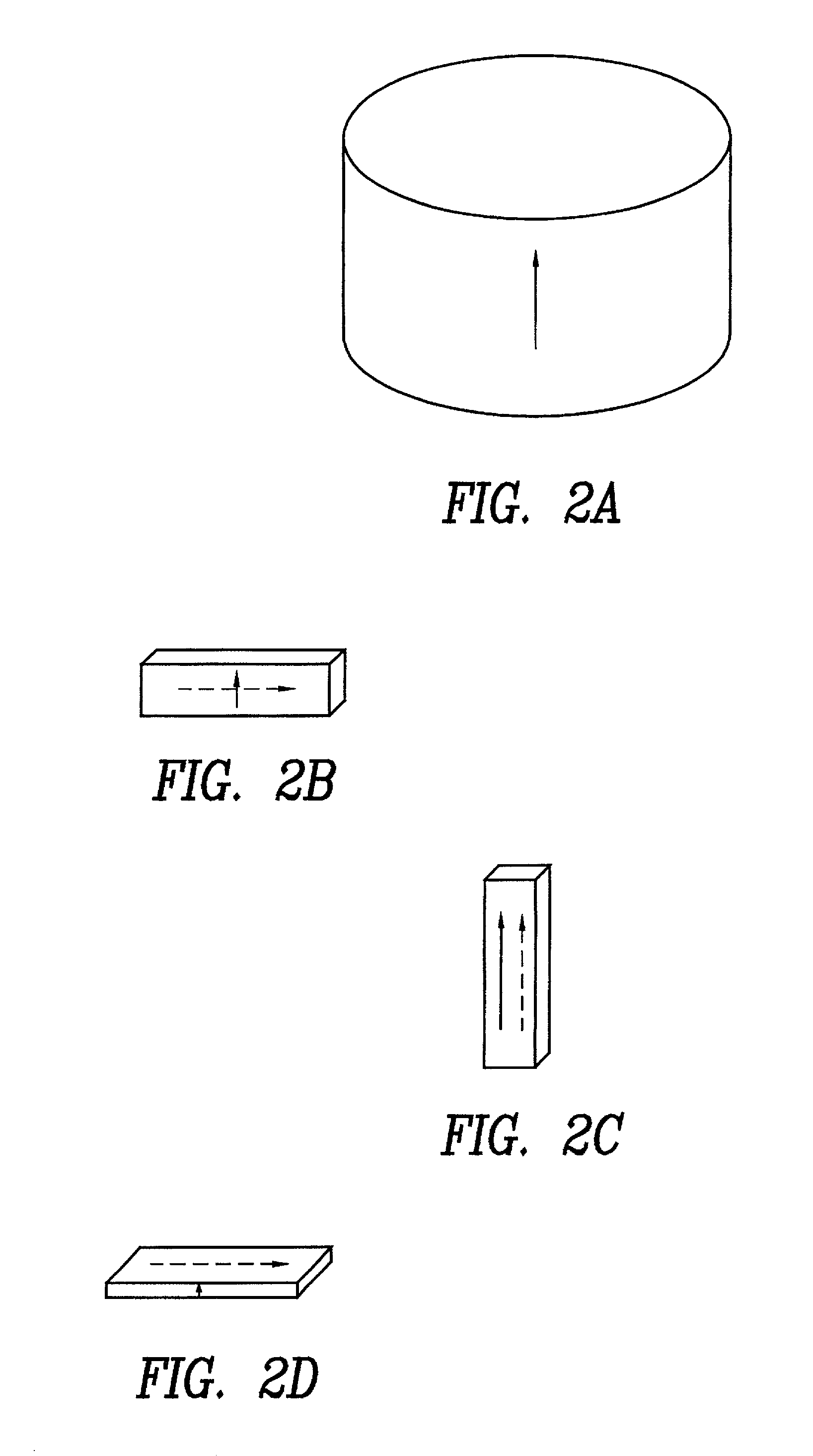

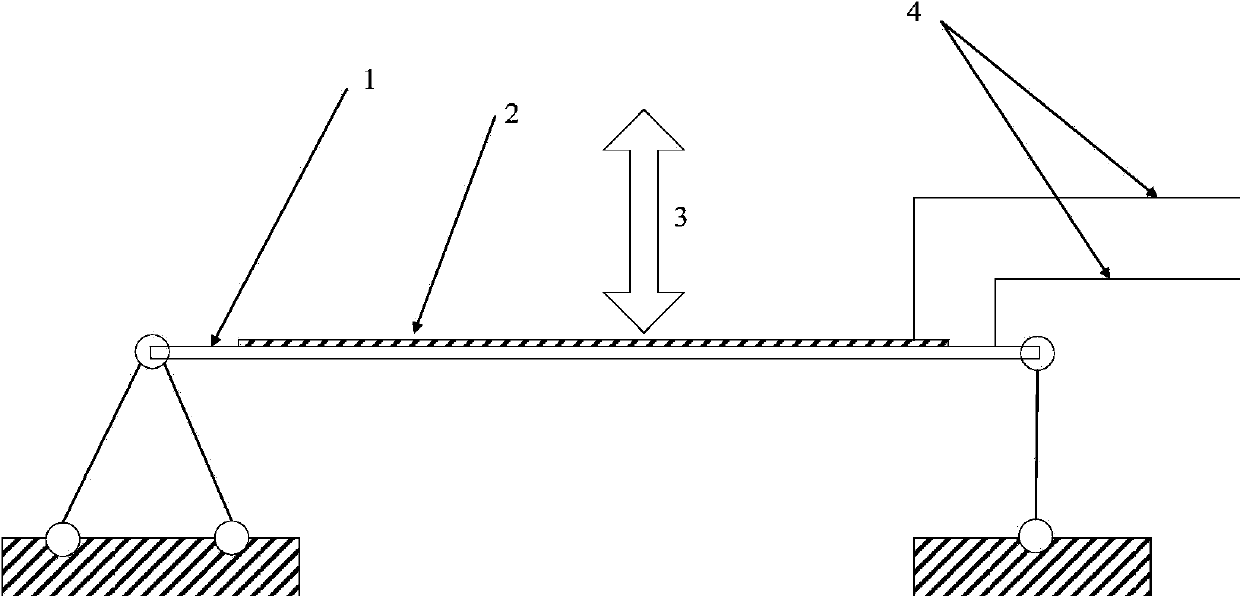

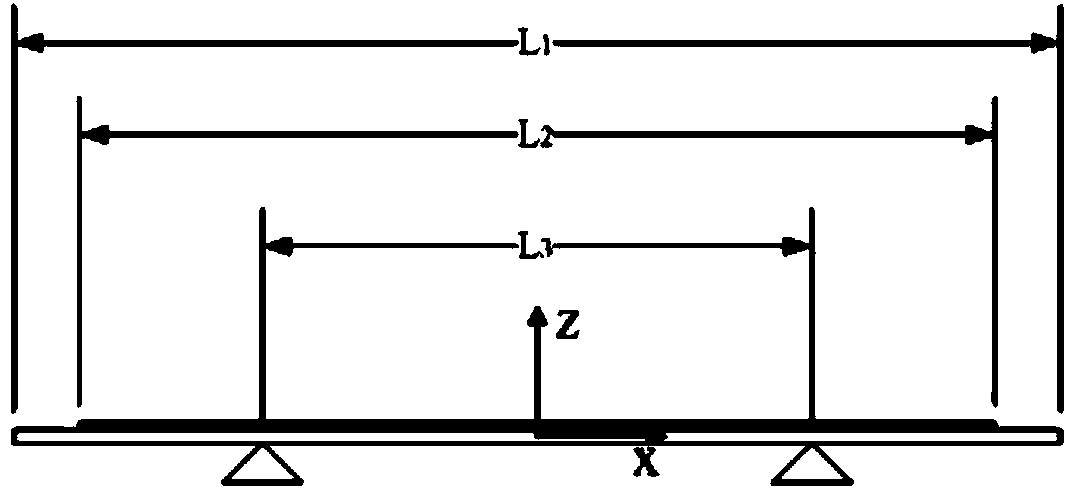

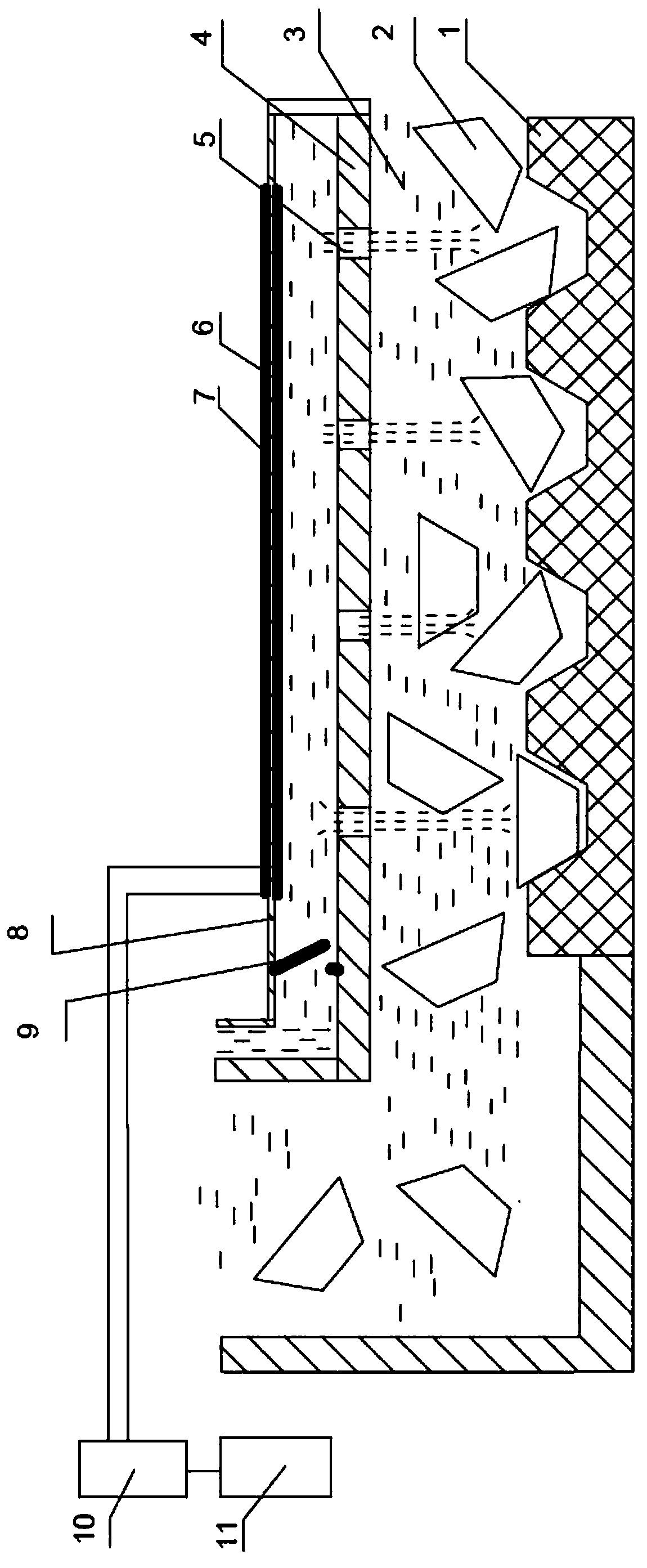

Piezoelectric energy trapping and detecting method based on external forced vibration

ActiveCN104218847AEffective deformationSimple structurePiezoelectric/electrostriction/magnetostriction machinesCurrent/voltage measurementCapacitanceFull bridge

The invention discloses a piezoelectric energy trapping and detecting method based on external forced vibration. According to the method, by means of adoption of a beam and slab structure and a simple support supporting mode, energy trapping for piezoelectrics is achieved by forced vibration. The method includes: firstly, converting forced vibration mechanical energy into alternating-current signals according to a piezoelectric effect; then, utilizing a full-bridge rectification circuit for rectifying the alternating-current signals; finally, utilizing a capacitance filtering circuit for achieving stable direct current output. According to design, a switching circuit with a light-emitting diode and an oscilloscope is provided for achieving qualitative and quantitative detection of an energy trapping process. The piezoelectric energy trapping and detecting method based on external forced vibration has the advantages that detection is simple, convenient and accurate, energy trapping is simple and stable in supporting, dependency on vibration frequencies of external vibration sources is weak, and the method is promising in application prospect on the aspect of self-energy-supply of low-energy-consumption electronic devices.

Owner:HANGZHOU DIANZI UNIV

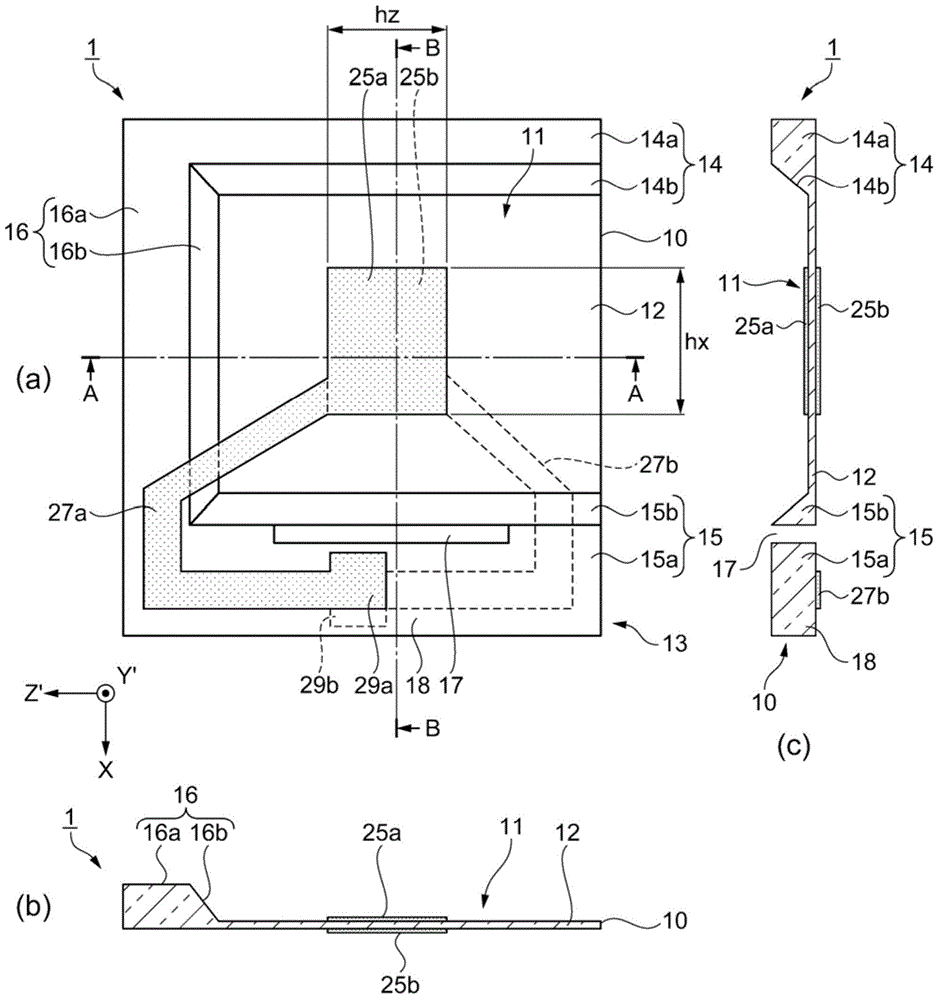

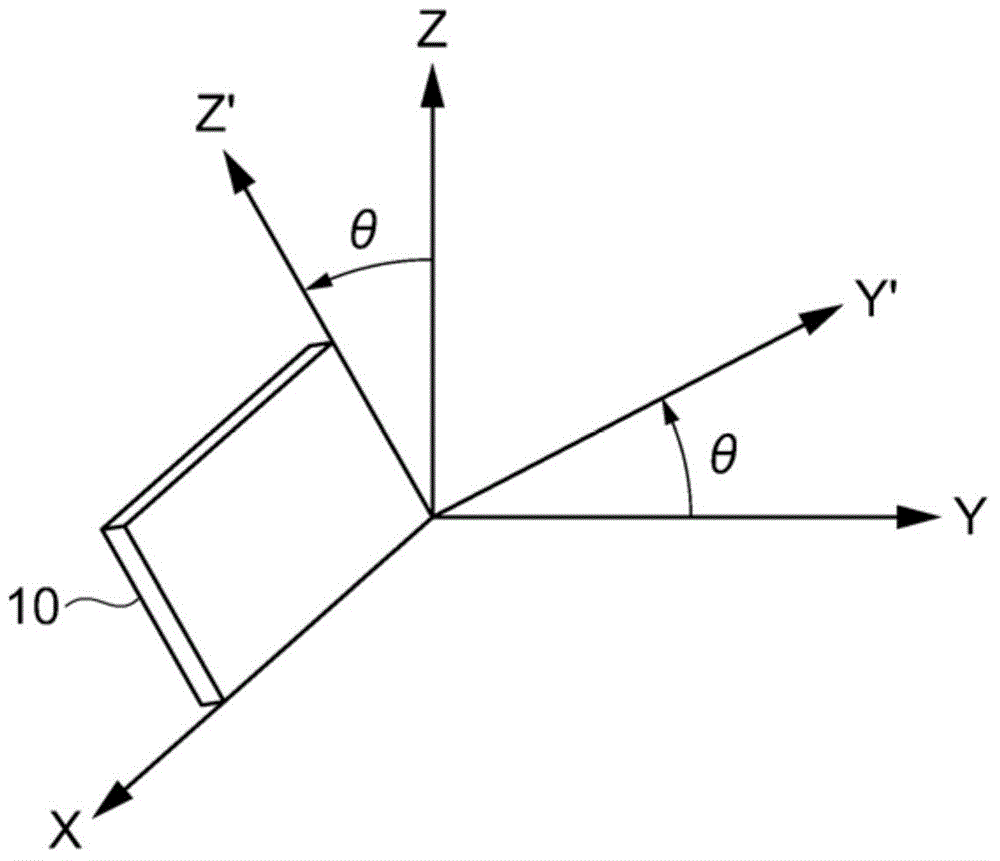

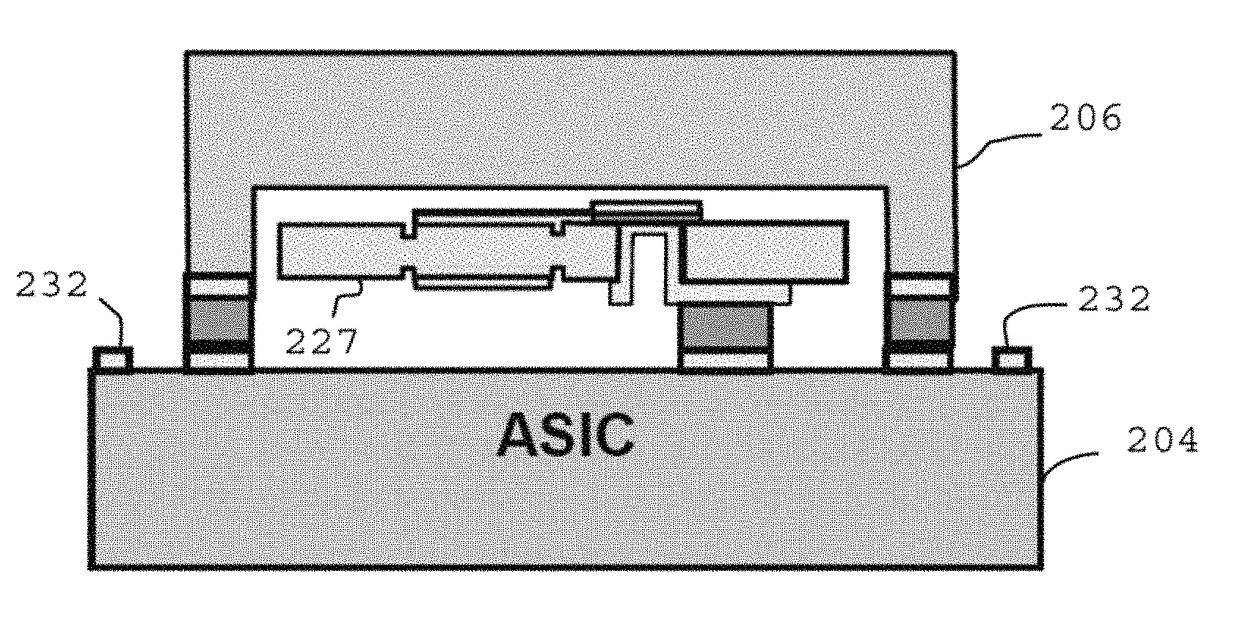

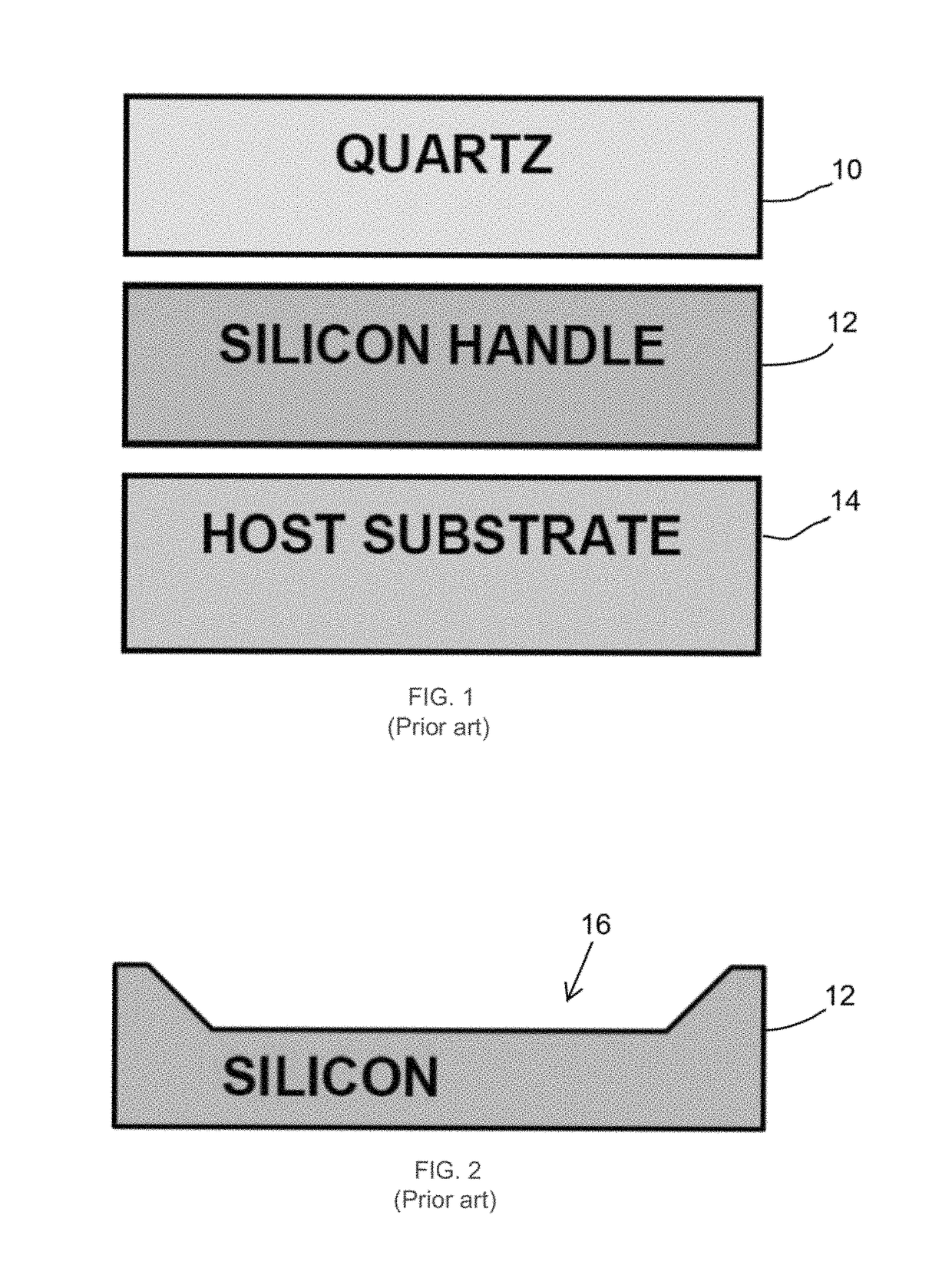

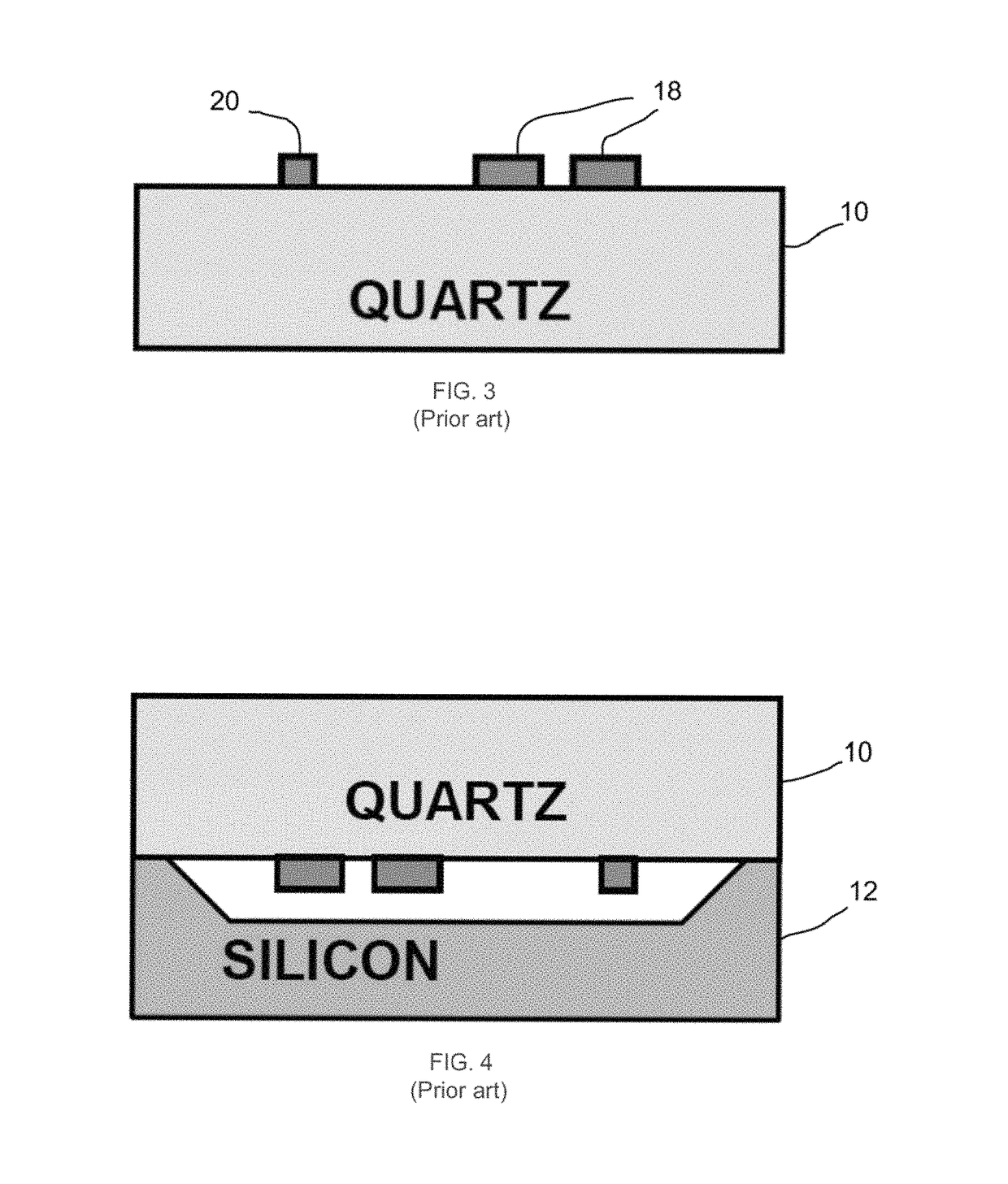

High Q quartz-based MEMS resonators and methods of fabricating same

ActiveUS9985198B1Guaranteed uptimeImprove device yieldPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAdhesiveMicrometer

High-yield fabrication methods are provided for making quartz resonators having thicknesses ranging from one micrometer to several hundred micrometers and thus covering the frequency range from HF to UHF. Plasma dry etching is used to form arbitrary resonator geometries. The quartz resonator structure and the through-quartz vias are formed concurrently. The method includes bonding a quartz device wafer to a quartz handle wafer with a temporary adhesive. Mesa structures formed by plasma dry etching enable the resonators to achieve high-Q operation with energy trapping / mode confinement. A thermo-compression bond integrates the quartz resonators to a host wafer (e.g., an oscillator ASIC) to form oscillators. Silicon cap wafers are bonded over the resonators to the ASIC to provide wafer scale hermetic encapsulation of the quartz oscillators.

Owner:HRL LAB

Processing method for manufacturing crystal base plate of quartz-crystal resonator

ActiveCN105141271AImprove electrical performance parametersReduce spreadImpedence networksQuartz crystal resonatorElectricity

The invention discloses a processing method for manufacturing a crystal base plate of a quartz-crystal resonator. The processing method comprises steps of using chemical solvent to process and erode the crystal base plate according to preset size of erosion area and erosion time, thereby achieving that thickness of a designated area of the crystal base plate is changed according to preset design and form, and achieving the edge chamfering effects of chemical erosion; and then manufacturing the crystal resonator. The chemical solvent is hydrogen fluoride NH4HF2 solution. Segmentation and partition erosion can be used in the method, and the method is characterized by low cost, short time, controllable surface damage and less loss. As a novel quartz-crystal processing technology and method, electrical performance parameters of the resonator can be improved. The processing method is characterized in that performance parameters of materials can be changed; the specific mode of the thickness or rigidity of the designed crystal plate is changed; energy trapping performance of the crystal resonator is achieved; and quite small shearing vibration on the edge of the crystal plate are ensured, thereby reducing diffusion of energy towards outside and achieving the objective to enhance shearing vibration.

Owner:JIANGSU HAIFENG ELECTRONICS

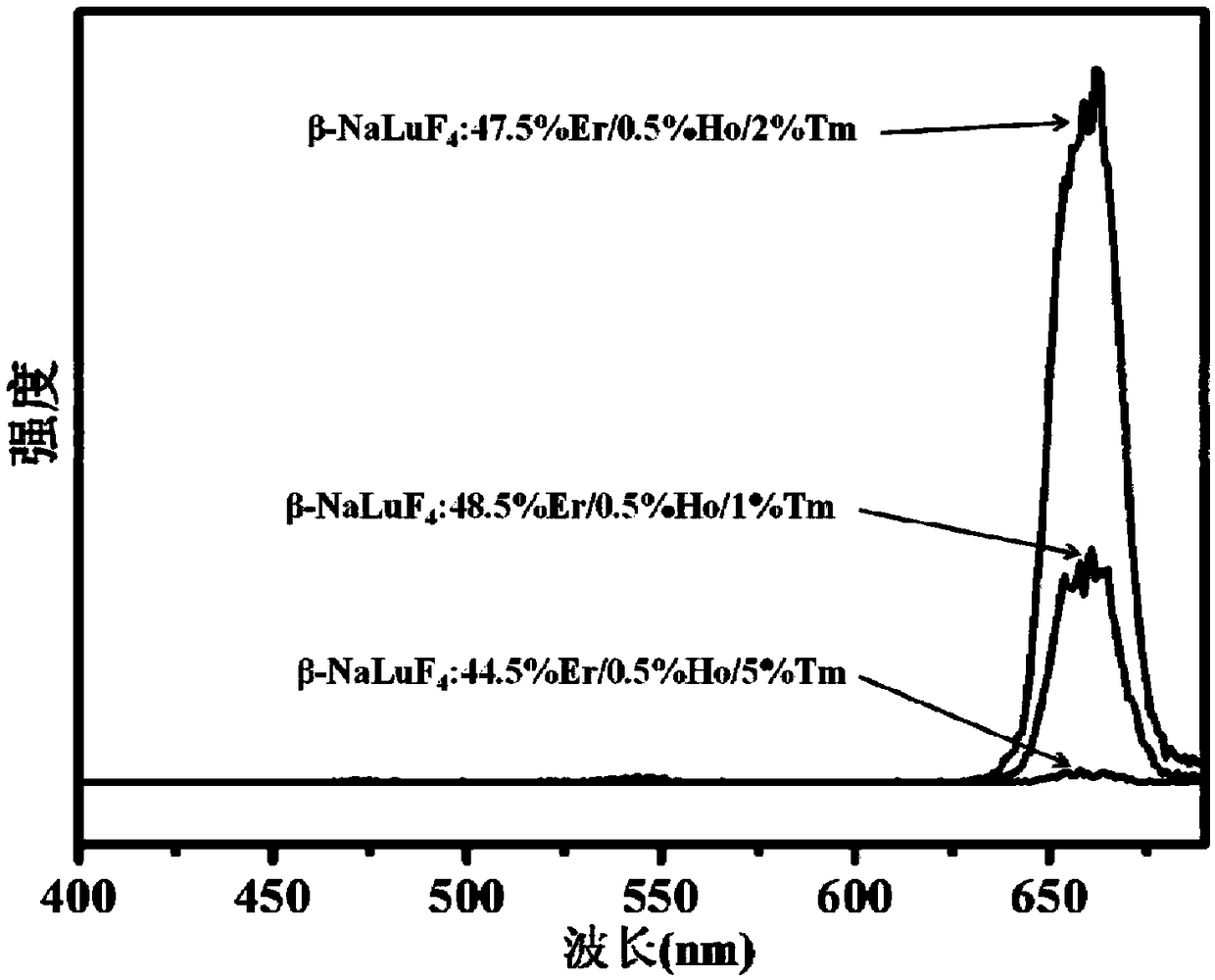

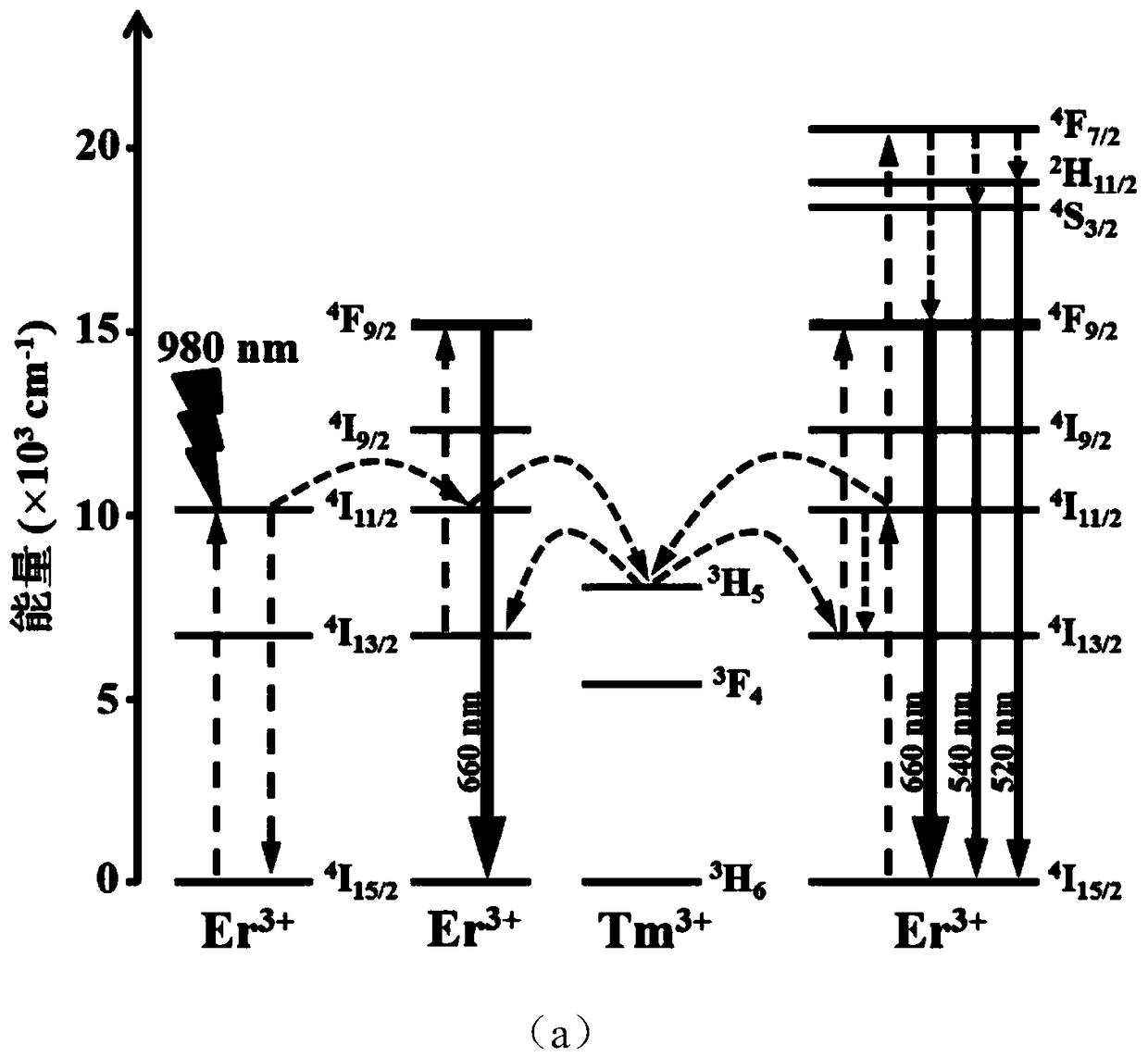

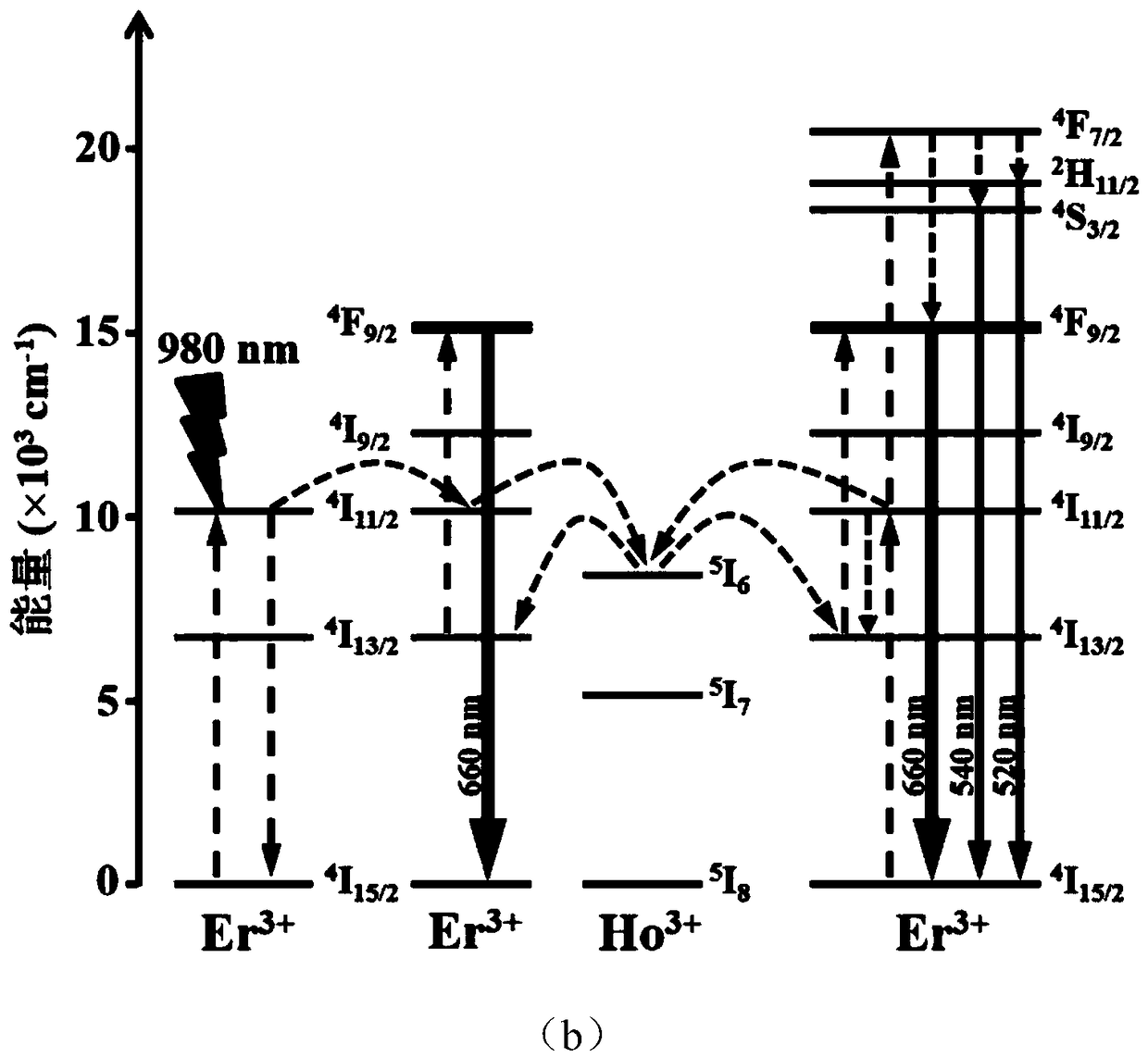

Erbium ion sensitized upconversion phosphor as well as preparation method and application thereof

ActiveCN109337687AHigh strengthHigh purityLuminescent compositionsUpconversion luminescenceHigh intensity

The invention belongs to the technical field of luminescent materials and particularly relates to erbium ion sensitized upconversion phosphor as well as a preparation method and an application thereof. According to the upconversion phosphor, NaLuF4 is taken as a substrate, Tm<3+> and Ho<3+> are taken as energy trapping centers, and Er<3+> is taken as sensitization ions and activation ions. Er<3+>is taken as the sensitization ions and the activation ions simultaneously in a high Er<3+> doping manner, and red upconversion luminescence with high impurity can be obtained. Doping concentration ofEr<3+> can be reduced by adopting Tm<3+> and Ho<3+> as the energy trapping centers simultaneously, so that the probability of concentration quenching is reduced effectively, and red upconversion luminescence with high purity, high intensity and high red-green ratio is realized more easily. The preparation process of the upconversion phosphor is simple, short in period, easy to operate, pollution-free and suitable for large-scale production, and equipment cost is low. The obtained upconversion phosphor has broad application prospect in the fields of bioimaging, solar cells, solid lasers, devicedisplay and the like.

Owner:GUANGZHOU UNIVERSITY

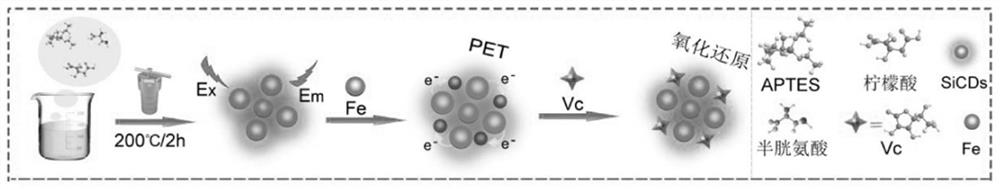

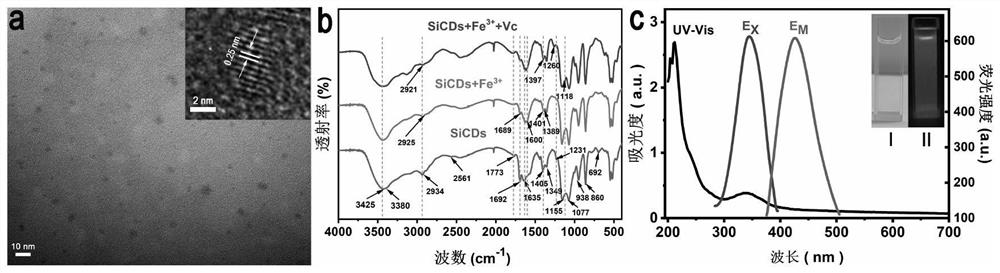

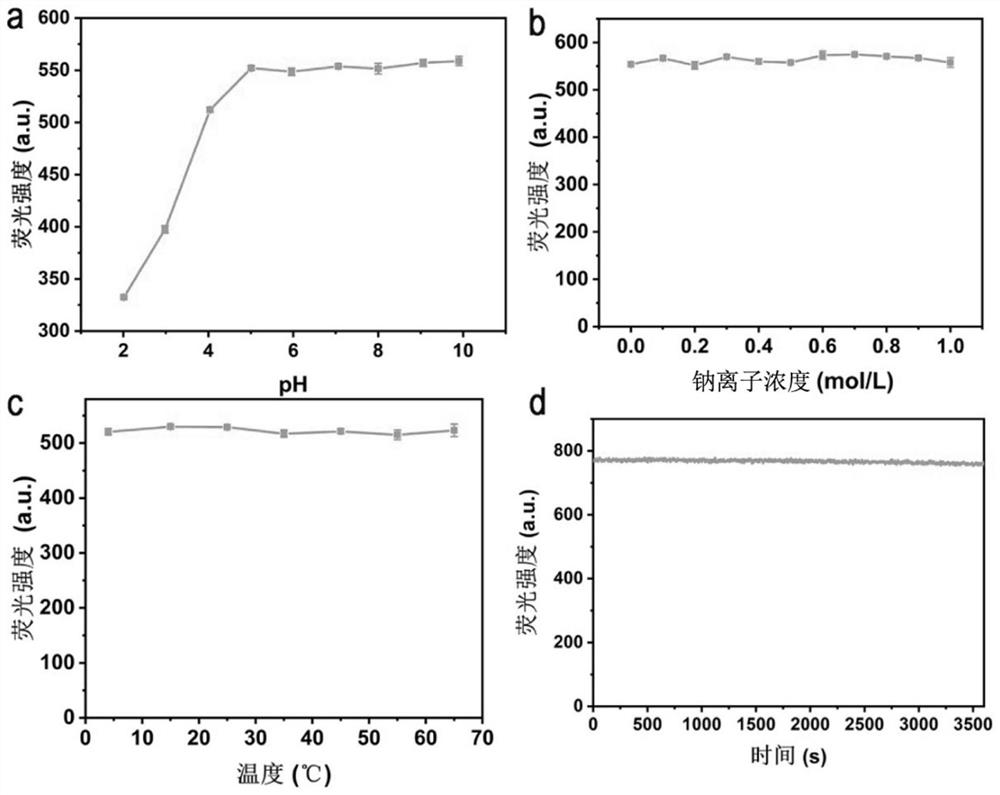

Preparation method and application of silicon-carbon quantum dots

ActiveCN114032095AStrong blue fluorescenceImprove thermal stabilityMaterial nanotechnologyNanoopticsNitrogen gasEnergy trapping

The invention provides a preparation method and application of silicon-carbon quantum dots. The preparation method of the silicon carbon quantum dots (SiCDs) comprises the following steps: firstly, dissolving citric acid and cysteine in deionized water, carrying out ultrasonic dissolution, and carrying out nitrogen bubbling; injecting 3-aminopropyltriethoxysilane into the nitrogen-saturated precursor solution, transferring the obtained solution into a stainless steel autoclave with a polytetrafluoroethylene lining, and conducting incubation for 2 h at the temperature of 200 DEG C; and after cooling to room temperature, purifying the obtained mixture through a dialysis bag to obtain a SiCDs solution. According to the invention, an off-on fluorescence sensor is ingeniously designed by applying the SiCDs to detect the Vc, the fluorescence of the SiCDs can be quenched by Fe<3+> through IFE and PET, the Vc can recover an energy trap caused by a redox reaction and -NH2 / -OH exposure, and the new strategy based on the off-on of the effective fluorescence can be used for detecting the Vc.

Owner:HEBEI UNIVERSITY

Thickness extensional piezoelectric resonator

ActiveUS7446454B2Change frequencyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceAcoustics

Owner:MURATA MFG CO LTD

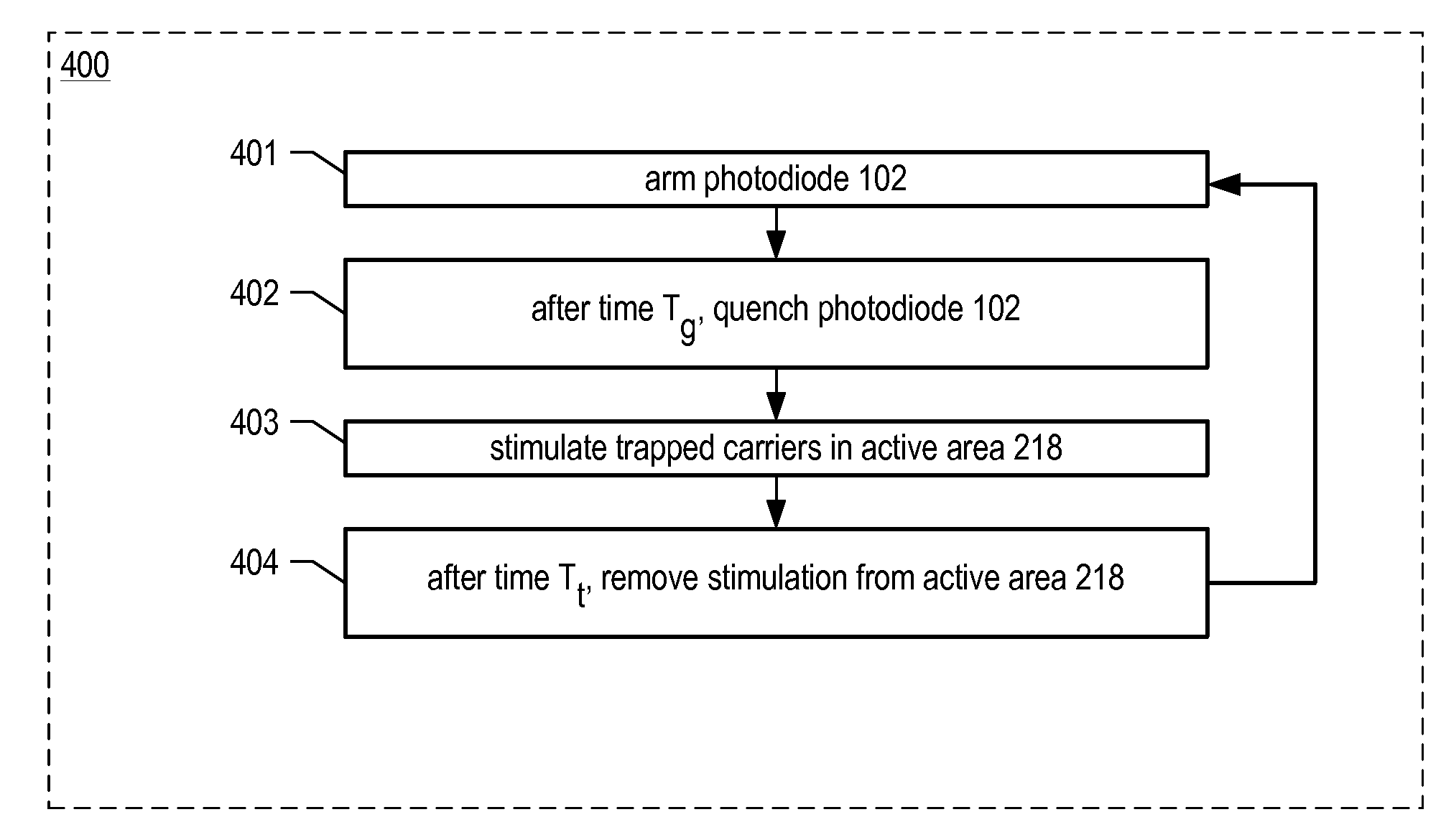

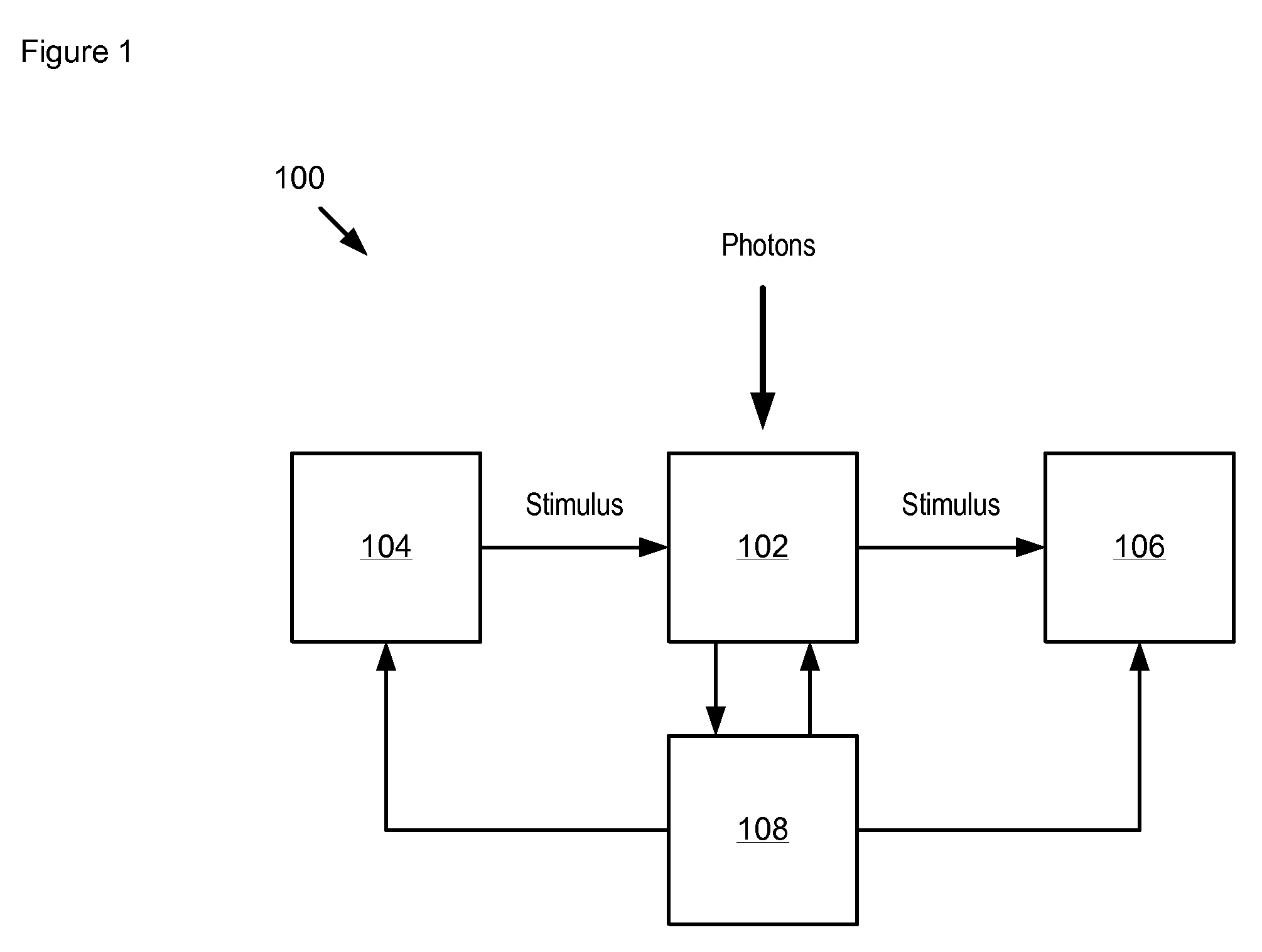

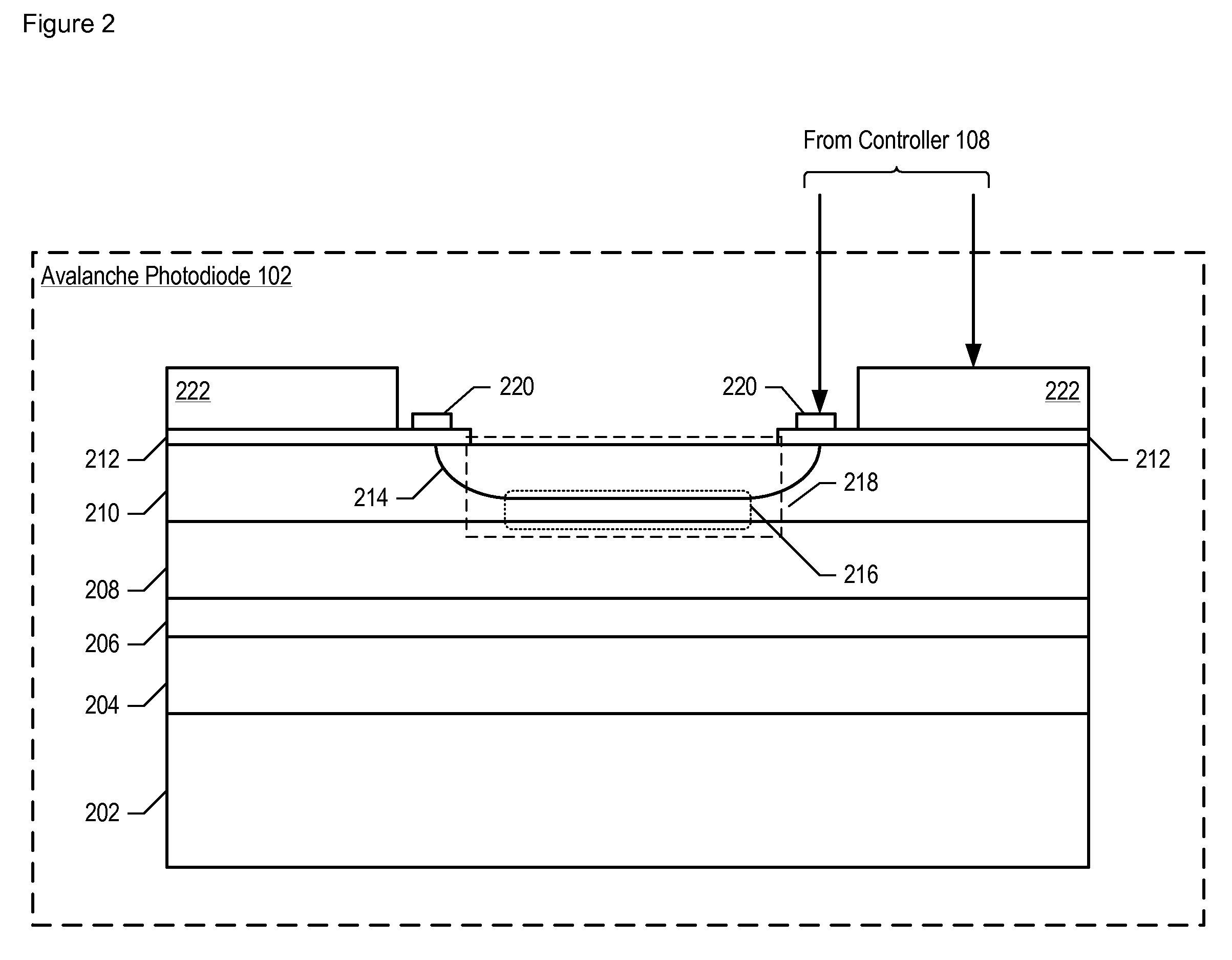

Apparatus comprising a single photon photodetector having reduced afterpulsing and method therefor

ActiveUS7626193B2Shorten the counting processReduce probabilityTransistorPhotometryPhotovoltaic detectorsPhotodetector

Owner:LG INNOTEK CO LTD

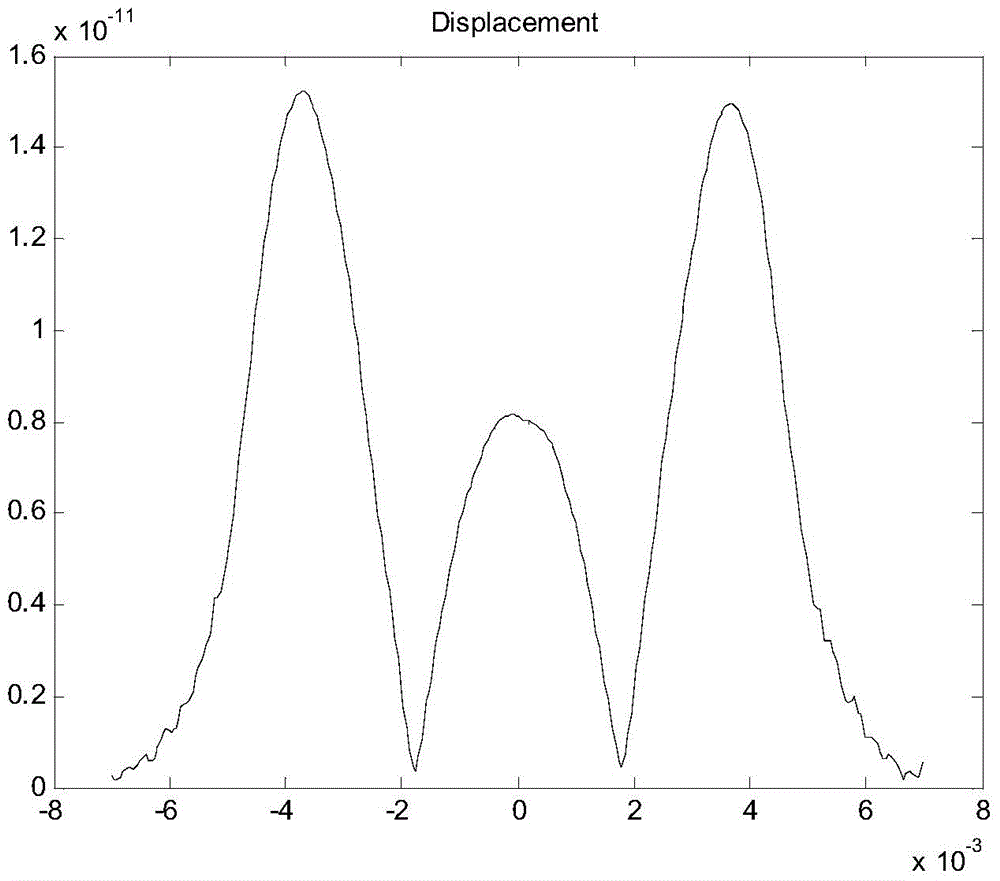

QCM (quartz crystal microbalance) sensor with high-quality factor and high-quality sensitivity

InactiveCN104807717AHigh quality factorHigh Quality Factor High Mass SensitivityWeighing by absorbing componentElectrical conductorQuartz crystal microbalance

The invention discloses a QCM (quartz crystal microbalance) sensor with high-quality factor and high-quality sensitivity. A resonant bottom plate with an inverted desk type circular groove in a single surface is adopted, the quality of the peripheral region (a circular ring-shaped platform) of the circular groove of the resonant bottom plate is improved, the layout of an upper metal electrode comprising a circular ring-shaped electrode covering the surface of the circular ring-shaped platform and a circular electrode covering the surface of the circular groove is adopted, and the circular ring-shaped electrode is communicated with the circular electrode through metal conductors, so that an energy trapping effect and an energy concentration effect are improved and the quality factor of the QCM sensor is improved. Meanwhile, the purpose of improving the quality sensitivity of the QCM sensor is achieved by reducing the thickness of partial effective resonant region.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

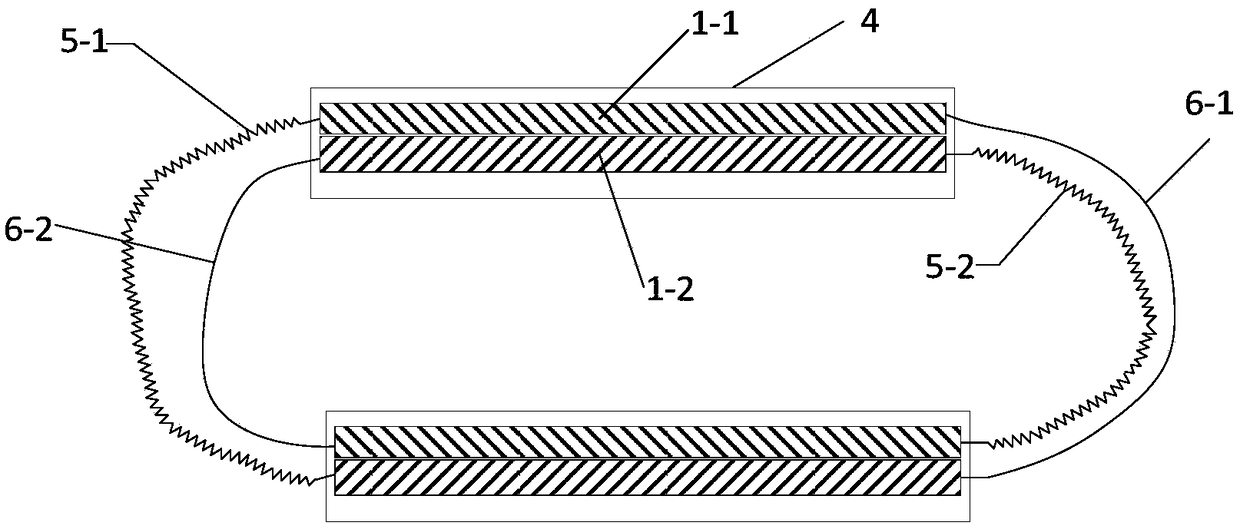

Sliding electrostatic energy trapping device for human heart beating

ActiveCN108880318AExtended service lifeHigh energy conversion rateFriction generatorsHigh energyEngineering

The invention provides a sliding electrostatic energy trapping device for human heart beating. The energy trapping device is applied to the collecting of the energy of human heart beating. The energytrapping device comprises two energy trapping parts and an attachment part. The energy trapping part comprises an inner substrate, an outer substrate and a dielectric material layer arranged on the surface of the substrate. The dielectric material layers on the inner and outer substrate surfaces are in contact with each other and have opposite polarities. The dynamic signals of heart beating are transmitted to the energy trapping units through the attachment unit, so that friction occurs between the dielectric material layers on the surface of the inner and outer substrates, positive and negative charges are generated respectively, and potential energy is formed and input to the implantable electronic equipment. The invention has the advantages of long service life, easy integration with other processing processes and high energy conversion rate.

Owner:ZHEJIANG UNIV

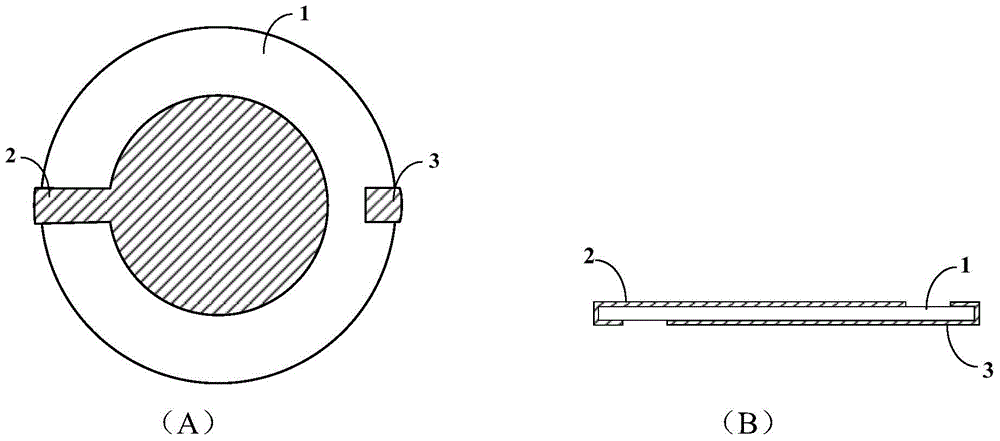

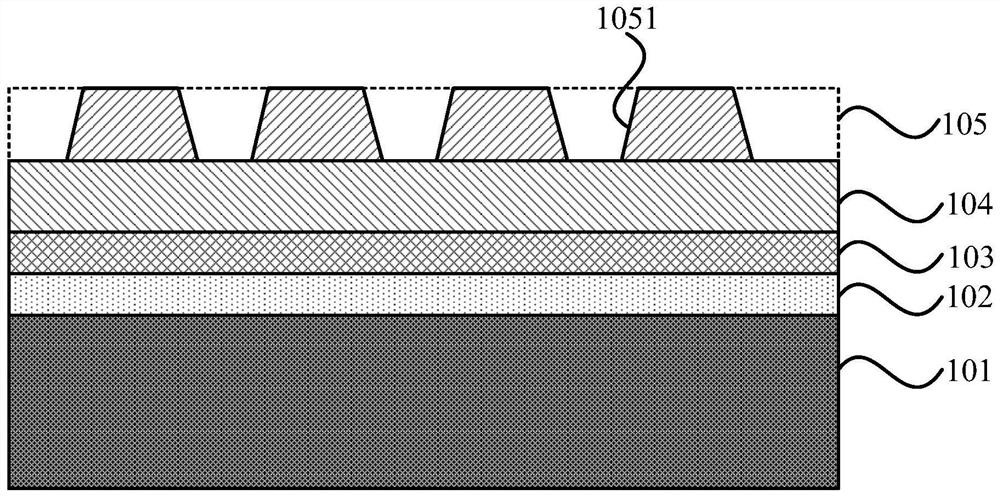

Piezoelectric quartz crystal wafer with single convex structure

InactiveCN105007056AImprove protectionEnhanced trapping effectImpedence networksConvex structureWafering

The invention discloses a piezoelectric quartz crystal wafer with a single convex structure. The piezoelectric quartz crystal wafer comprises a central component (1), a protecting frame (2) and a connecting part (3). A cavity is arranged in the protecting frame (2); the central component (1) is arranged in the cavity; a boss (4) is arranged at the top surface of the central component (1); through grooves A (5) are formed among the two long sides of the protecting frame (2) and the two long sides of the central component (1); through grooves B (6) are formed among the two short sides of the protecting frame (2) and the two short sides of the central component (1); the through grooves A (5) are communicated with the through grooves B (6). The connecting part (3) is arranged at any one of the through groove B (6). The piezoelectric quartz crystal wafer of the invention has the following benefits: the piezoelectric quartz crystal wafer of the invention could be used for performing batch production to the small quartz crystal wafer, weakening parasitic vibration generated by the edge, and strengthening energy trapping effect of the centre of the quartz crystal wafer, thereby improving working accuracy and greatly improving consistency of the product.

Owner:CHENGDU TIMEMAKER CRYSTAL TECH

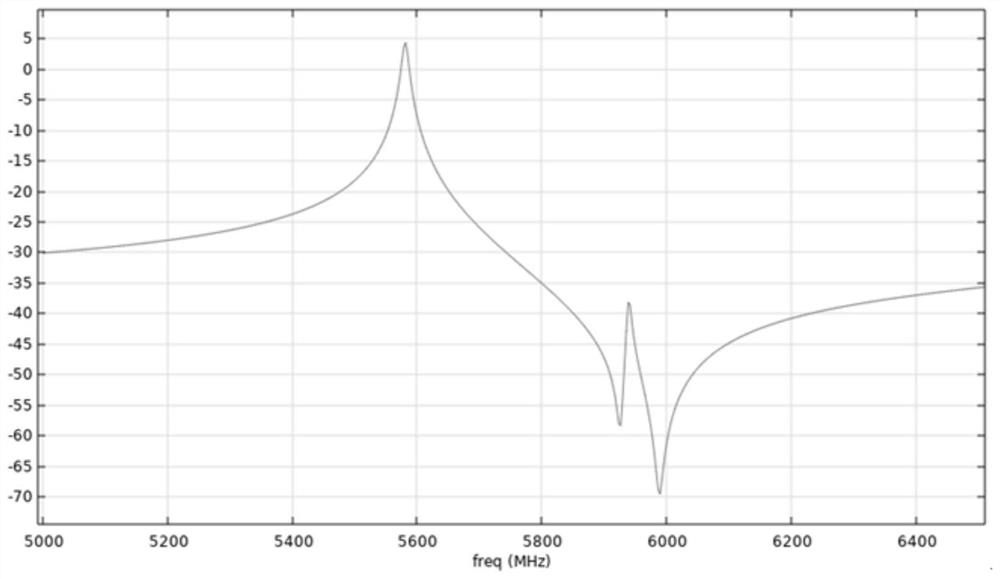

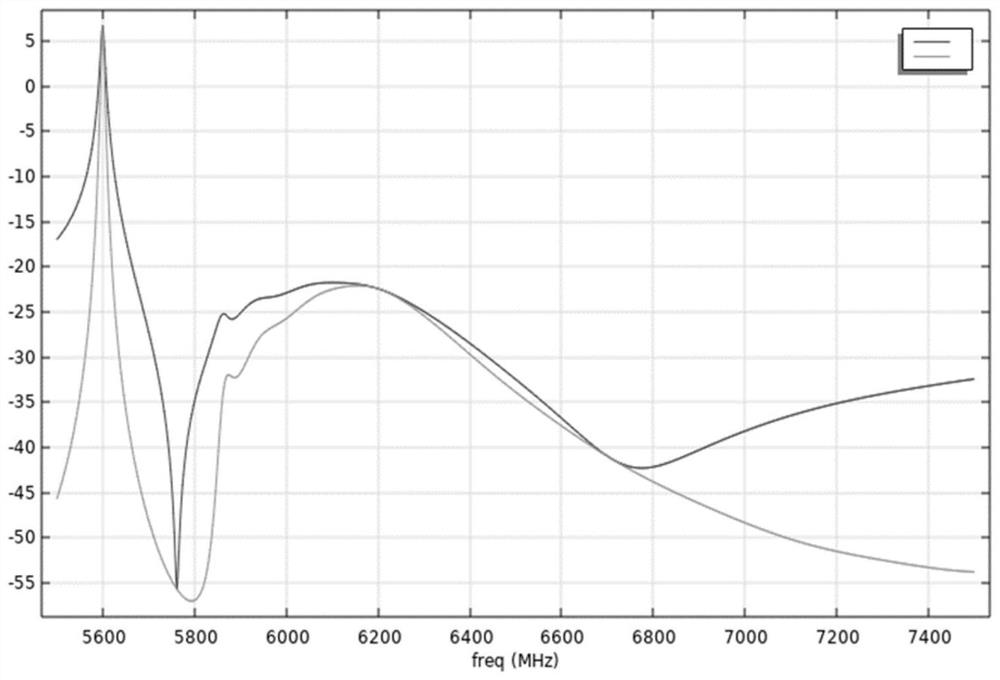

Surface acoustic wave resonator and filter

PendingCN114244311AImprove stabilityIncrease working frequencyImpedence networksEngineeringSurface acoustic wave resonators

The embodiment of the invention discloses a surface acoustic wave resonator and a filter. The resonator comprises a supporting layer, an energy trap layer, a temperature compensation layer, a piezoelectric layer and an interdigital transducer layer which are sequentially stacked, the interdigital transducer layer comprises a plurality of interdigital transducers, the material of the piezoelectric layer comprises X-40Y lithium niobate, the acoustic bulk wave propagation velocity of the support layer is greater than the acoustic surface wave propagation velocity of the piezoelectric layer, and the energy trap layer is used for capturing parasitic charges on the surface of the support layer to improve the Q value of the acoustic surface wave resonator. According to the embodiment of the invention, the piezoelectric layer and the supporting layer of the resonator are improved, and the speed of transmitting sound waves by X-40Y lithium niobate is relatively high, so that the working frequency of the resonator is greatly improved and reaches 5G and more than 5G; the acoustic bulk wave propagation speed of the supporting layer is greater than that of the surface acoustic wave propagation speed of the piezoelectric layer, energy is limited on the surface, and bulk wave leakage is avoided, so that the device loss is reduced; the energy trap layer can improve the Q value to enhance the stability of the surface acoustic wave resonator.

Owner:MAXSCEND MICROELECTRONICS CO LTD

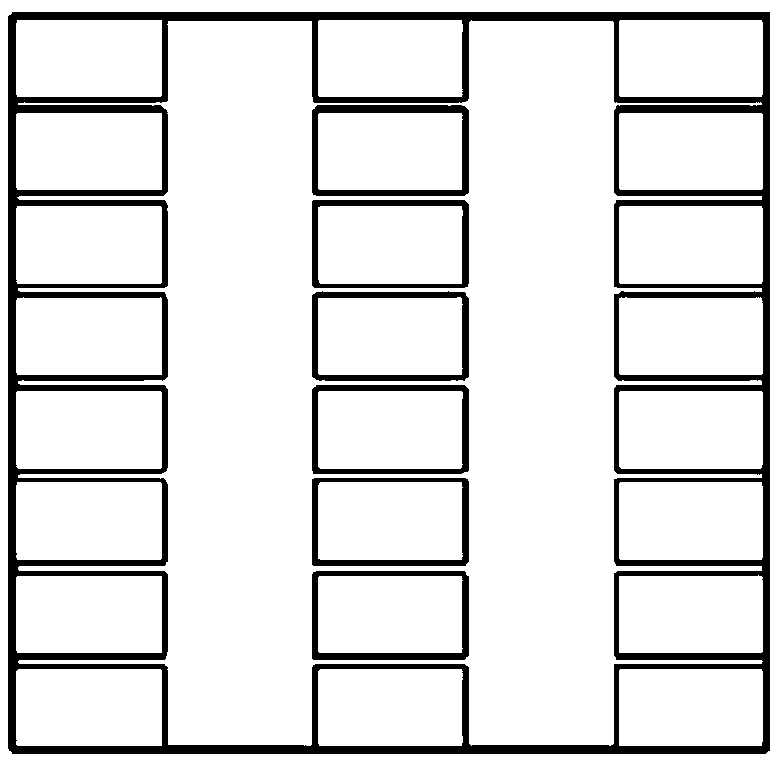

A device and method for self-assembly of micro-fluid stimulated micro-device

ActiveCN107644827BFully embedded implementationImprove assembly success rateSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

The invention discloses a self-assembling device and method for micro-fluid excitation micro-components. The device includes a substrate and a spacer. The substrate has an array of etched pits. Each pit matches the shape of a micro-element. The micro-element is carried by a carrier solution. The spacer and the substrate form an assembly cavity. There are micro-jet arrays corresponding to the pits on the substrate, and two curved piezoelectric vibrators are attached to the elastic film respectively. The one-way valve, the partition and the elastic film form a closed cavity, and the solution flows in from the one-way valve and flows out from the one-way valve. The micro-jet array is ejected, and the two curved piezoelectric vibrators are controlled by the driving power supply and the computer. The present invention utilizes piezoelectric vibration to fluidly excite the micro-components on the substrate that are not fully fitted with the substrate, so that the energy obtained exceeds the energy trap formed when some micro-components cannot be fully fitted with the substrate, and the micro-components and the substrate are fully integrated. Fitting; fluid excitation adopts piezoelectric drive, which can be digitally adjusted in frequency and excitation intensity to improve the success rate of assembly.

Owner:美泰(常州)控制系统有限公司

Piezoelectric vibrator

InactiveUS7583007B2Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksPiezoelectric actuatorsThird harmonic

An energy-trapping strip piezoelectric vibrator utilizing a third harmonic overtone of a thickness shear mode is provided. A piezoelectric vibrator 1 has a strip piezoelectric ceramic substrate 2 polarized in a longitudinal direction, and first and second excitation electrodes 3 and 4 provided on first and second principal surfaces 2a and 2b of the piezoelectric ceramic substrate 2. An excitation region 5 including a piezoelectric vibration portion that includes a portion where the first and second excitation electrodes 3 and 4 overlap and that utilizes harmonics of the thickness shear mode is formed. A region around the piezoelectric vibration portion is set as a non-excitation region. At least a region of the non-excitation region neighboring the piezoelectric vibration portion is a region having the same polarization axis direction as the excitation region 5 and a relatively small polarization degree or is an unpolarized region.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com