Novel piezoelectric quartz wafer with dual-convex structure and machining process thereof

A technology of piezoelectric quartz and wafers, applied in the manufacture/assembly of piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive devices, etc., can solve the cost Problems such as high level, low repeatability, and poor stability of the rolling process can achieve the effect of enhancing energy trapping effect, improving consistency, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

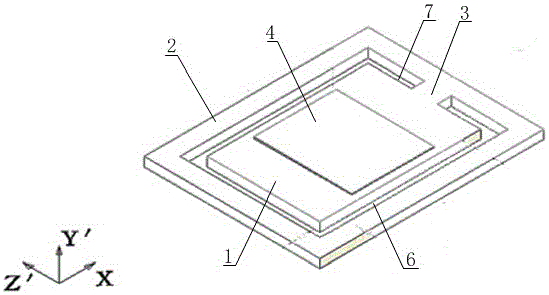

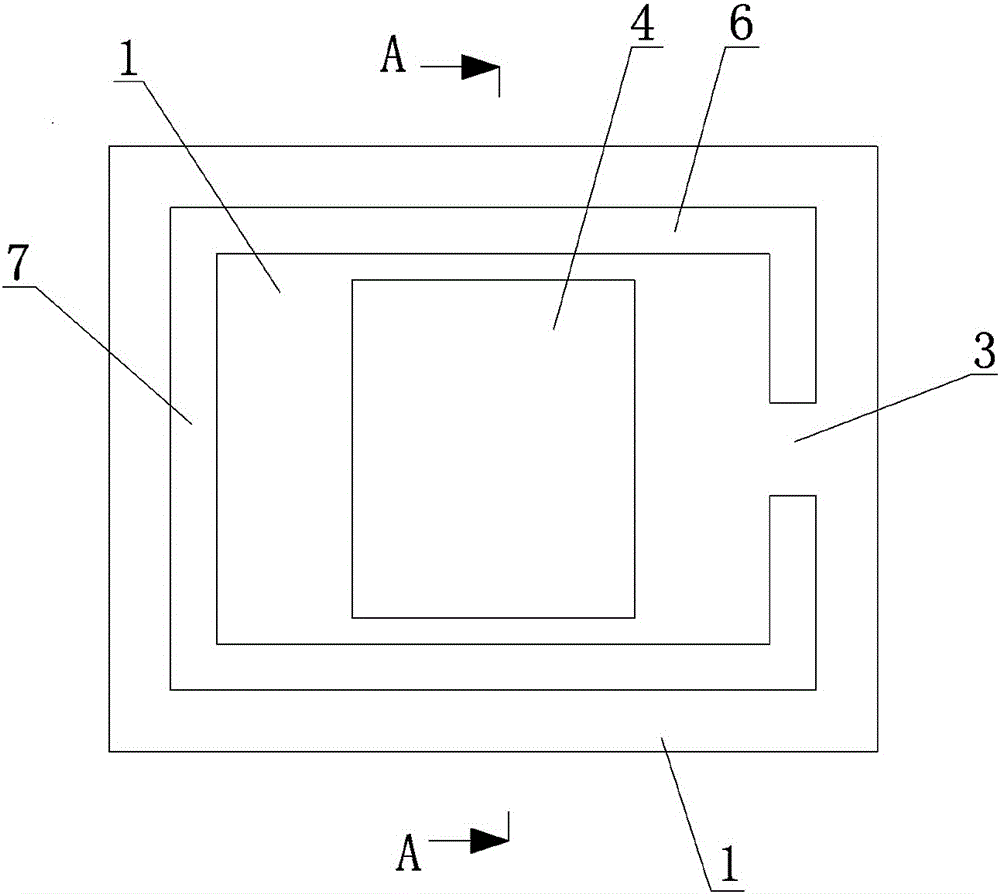

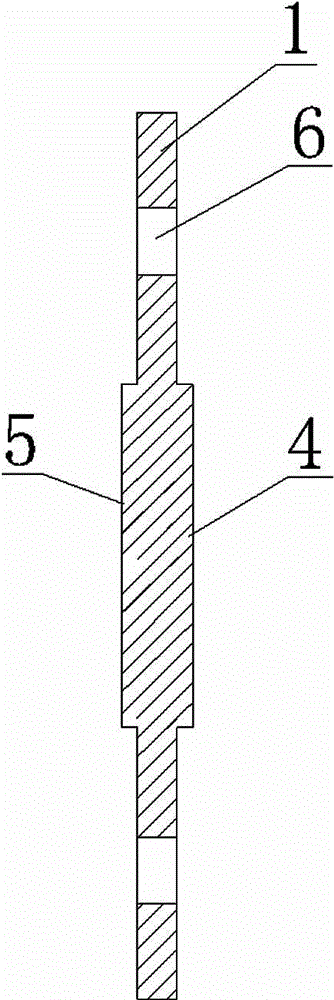

[0037] Such as Figure 1~4 As shown, a new type of piezoelectric quartz wafer with biconvex structure, the quartz wafer adopts AT cut type, this cut type is commonly used in quartz crystal resonators, in which the long side of the wafer is parallel to the X axis, and the X axis is the quartz The electrical axis of the crystal, the short side is parallel to the Z' axis, and the thickness direction is parallel to the Y' axis. It is not excluded that the long side of the quartz wafer is parallel to the Z' axis, the width is parallel to the X axis, and the thickness direction is parallel to the Y' axis. The piezoelectric quartz wafer includes a central member 1, a protective frame 2 and a connecting part 3. The central member 1, The materials of the protective frame 2 and the connecting part 3 are both quartz, and the central member 1 and the protective frame 2 are both in a rectangular shape, and a cavity is arranged in the protective frame 2, and the central component 1 is arran...

Embodiment 2

[0051] Such as Figure 7~9 As shown, the difference between the second embodiment and the first embodiment is that there are two connecting parts 3 connected between any short side of the protective frame 2 and the central member 1, and the central member 1 is added to the two connecting parts 3 And the mechanical strength between the protective frame 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com