Quartz crystal resonator with circular wafer structure and manufacture method thereof

A quartz crystal and resonator technology, applied in electrical components, impedance networks, etc., can solve the problems of difficult packaging, difficult to achieve, and high cost, and achieve the effects of simple packaging, simple process, and overall performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

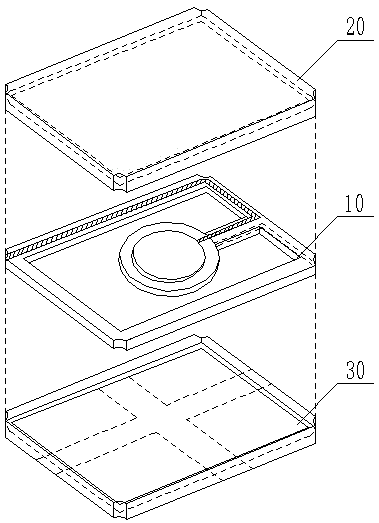

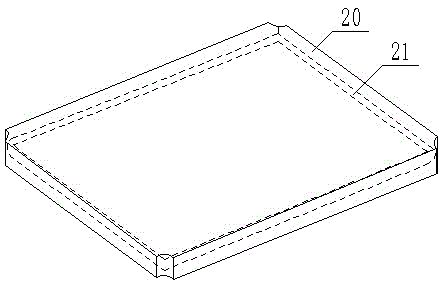

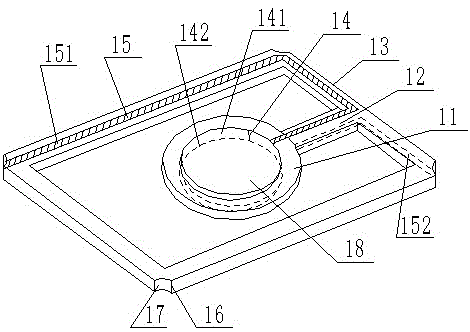

[0035] Such as Figure 1~Figure 7 As shown, a quartz crystal resonator with a circular wafer structure includes a quartz wafer 10 , a package cover 20 and a package base 30 . The quartz wafer 10 includes a circular member 11 , a connecting portion 12 and a protective frame 13 , the protective frame 13 is in the shape of a rectangle, and plays the role of support, packaging and connection. The circular member 11 is arranged at the center of the protective frame 13 and can vibrate freely. The circular member 11 is connected with a short frame of the protective frame 13 through the connecting portion 12. When the protective frame 13 is subjected to an external force, the force will not Transfer to the circular member 11, thereby protecting the circular member 11 well.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com