Processing method for manufacturing crystal base plate of quartz-crystal resonator

A quartz crystal and processing method technology, applied in the direction of electrical components, impedance networks, etc., to achieve the effect of reducing edge thickness, reducing diffusion, and strengthening shear vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

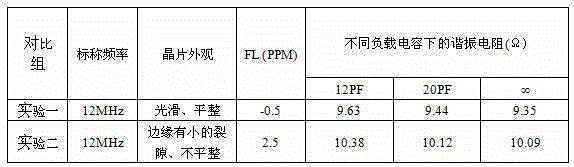

Examples

Embodiment 1

[0031] Embodiment 1, a method for processing a crystal substrate for manufacturing a quartz crystal resonator: the method utilizes a chemical solvent, and processes and erodes the crystal substrate according to a predetermined erosion area size and erosion time, so as to realize the thickness of the specified area of the crystal substrate according to The predetermined design form is changed to achieve the chamfering effect of chemical corrosion, and then made into a crystal resonator; the chemical solvent ammonia hydrogen fluoride NH 4 HF 2 aqueous solution.

Embodiment 2

[0032] Embodiment 2, in the processing method for the crystal substrate of the quartz crystal resonator described in the embodiment 1: the crystal substrate is a quartz crystal substrate or other crystal material substrates.

Embodiment 3

[0033] Embodiment 3, in a processing method for manufacturing a crystal substrate of a quartz crystal resonator described in Embodiment 1 or 2: the ammonia hydrogen fluoride NH 4 HF 2 The aqueous solution is ammonia hydrogen fluoride NH with a mass concentration of 45% dissolved at 40°C 4 HF 2 aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com