P-type polysilicon double-sided solar cell making method

A technology of solar cells and manufacturing methods, which is applied in the directions of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low utilization rate of the back surface and low conversion efficiency, and achieve the effect of improving structure and performance, and improving electrical performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

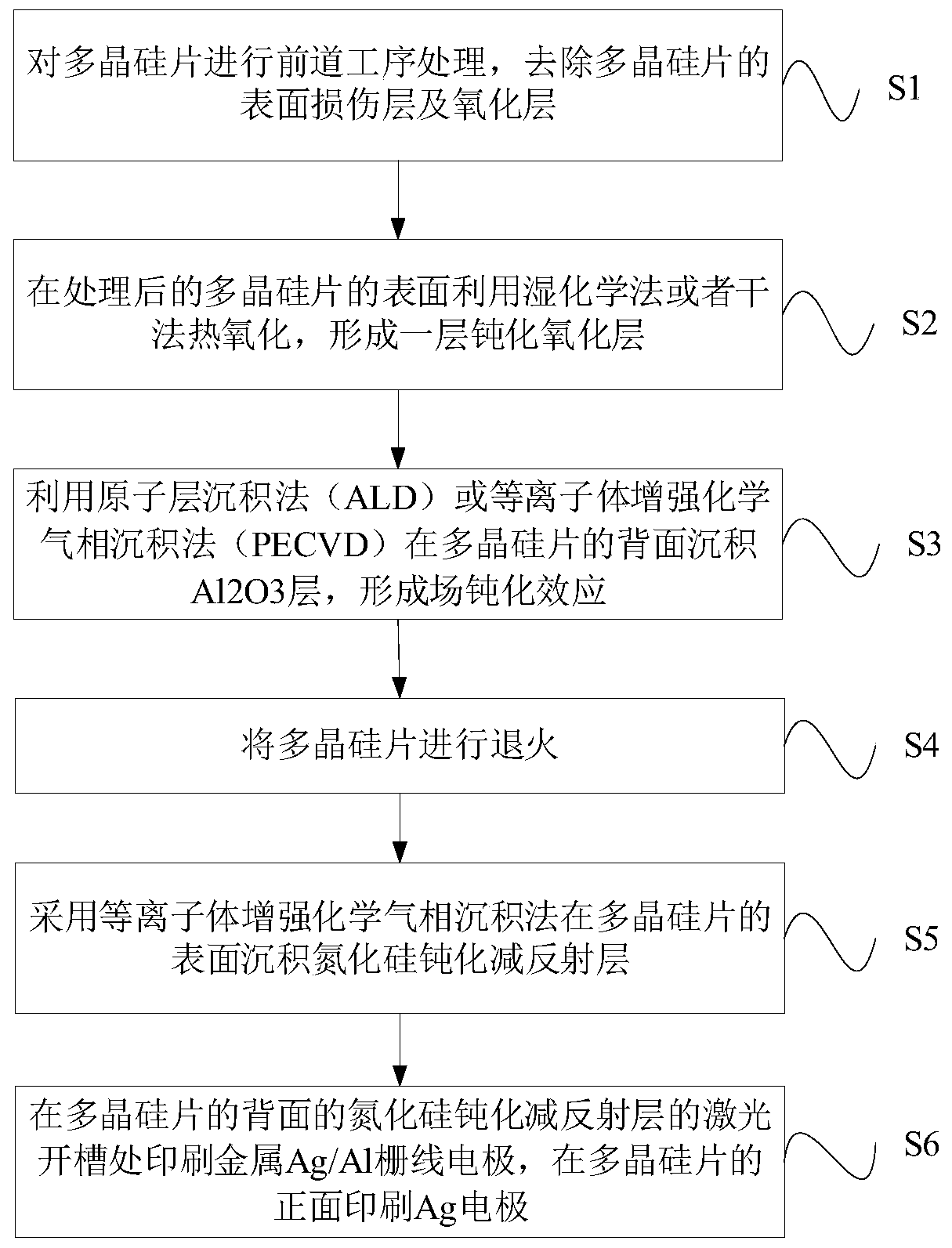

[0032] like figure 1 As shown, the present invention provides a kind of manufacturing method of P-type polysilicon double-sided solar cell, comprising:

[0033] Step S1, performing a pre-processing process on the polysilicon wafer to remove the surface damage layer and oxide layer of the polysilicon wafer;

[0034] Step S2, forming a passivation oxide layer on the surface of the treated polysilicon wafer by wet chemical method or dry thermal oxidation;

[0035] Step S3, using atomic layer deposition (ALD) or plasma enhanced chemical vapor deposition (PECVD) to deposit an Al2O3 layer on the back of the polysilicon wafer to form a field passivation effect;

[0036] Step S4, annealing the polysilicon wafer to further improve the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com