QCM (quartz crystal microbalance) sensor with high-quality factor and high-quality sensitivity

A high-quality, high-quality technology, applied in the fields of biology, physics, chemistry, materials, and piezoelectric sensors, it can solve the problems of harmfulness to the human body, expensive test samples, and uneven distribution of QCM sensor mass sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

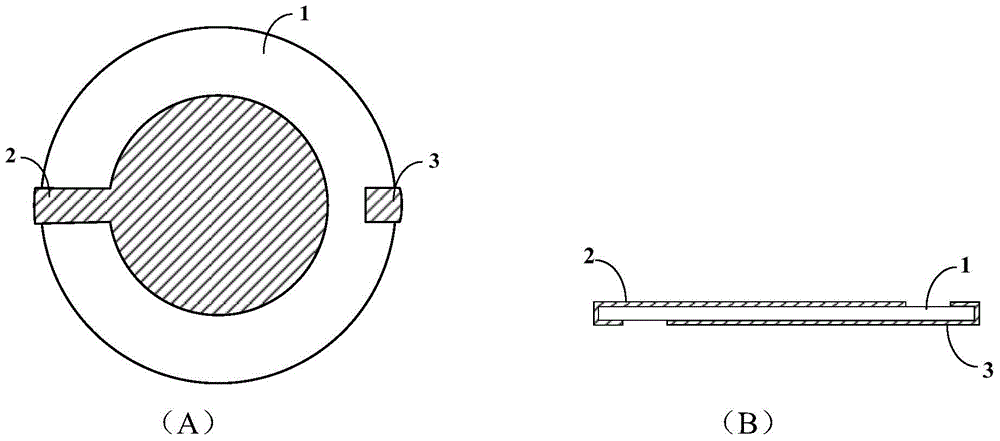

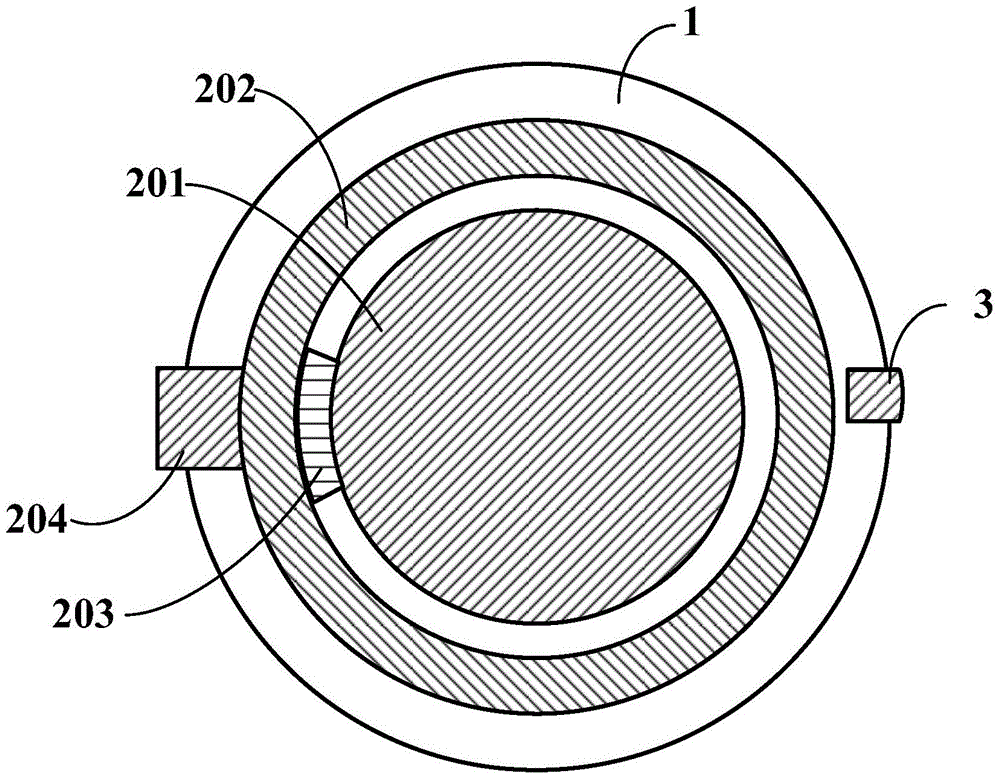

[0020] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

[0021] QCM sensors are very sensitive to mass, and are mostly used in the detection of micro traces and biochemical fields. In 1959, Saurebrey found that the frequency change of the QCM sensor was linearly related to the small mass change on its surface and gave an explicit expression, which was named Saurebrey equation.

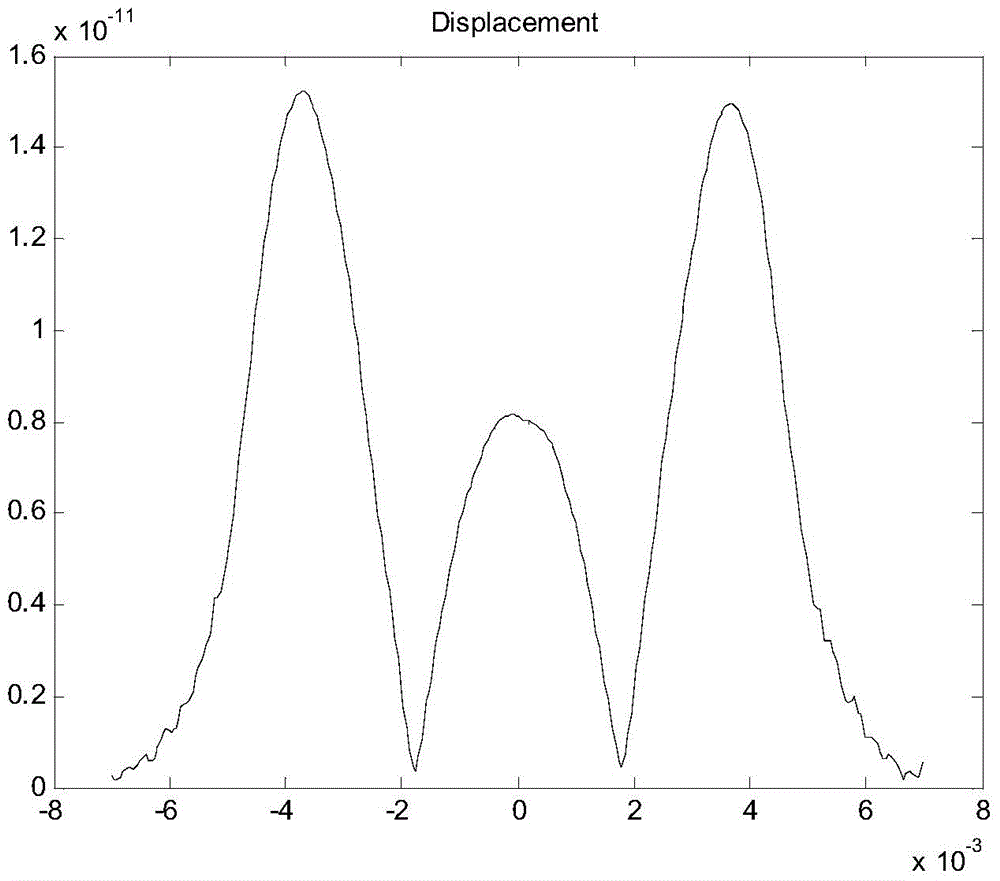

[0022] According to the Saurebrey equation, the mass sensitivity of the QCM sensor can be expressed by formulas (1) and (2):

[0023] C QCM = 2 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com