A device and method for self-assembly of micro-fluid stimulated micro-device

A self-assembly and micro-device technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low assembly efficiency, weakening the capillary force and surface tension of micro-components' self-gravity liquid bonding materials, and improving The success rate of assembly and the effect of solving the low efficiency of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

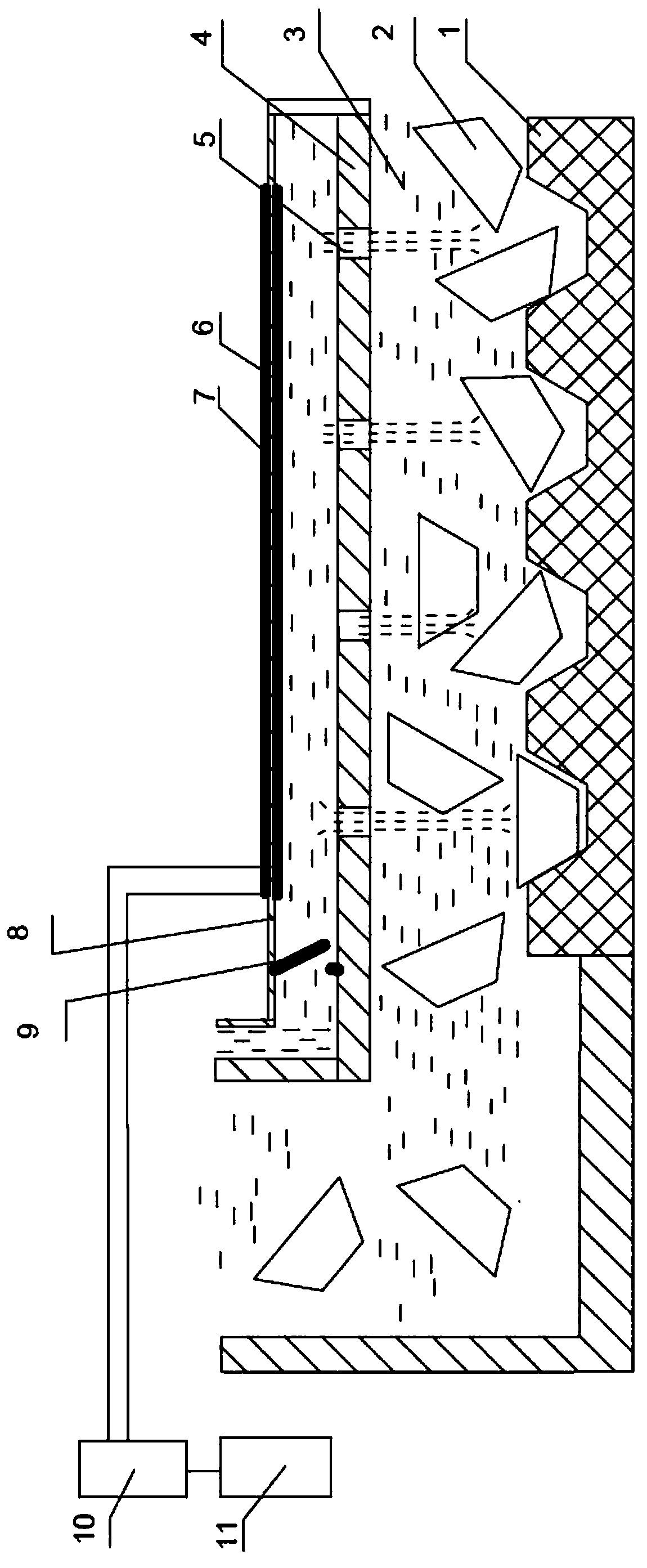

[0015] This embodiment provides a self-assembly device for micro-fluids to stimulate micro-devices, the structure of which is as follows: figure 1 Shown:

[0016] A substrate 1 such as silicon or glass has an array of pits of corresponding shapes etched out, and each pit is matched with a micro-element 2 of a specific shape manufactured from a silicon wafer. The micro-element 2 is carried by a carrier solution 3 and spaced The plate 4 is provided with a micro-spray array 5 corresponding to the pit on the substrate 1, and two curved piezoelectric vibrators (including the lower piezoelectric vibrator 6 and the upper piezoelectric vibrator 7) are attached to the metal elastic film 8 respectively, and the single The directional valve 9 , the partition 4 and the elastic film 8 form a closed cavity, and the fluid 3 can flow in from the one-way valve 9 and be ejected from the micro-spray array 5 . The two bending piezoelectric vibrators are controlled by a driving power source 10 an...

Embodiment 2

[0019] This embodiment provides a self-assembly method based on the self-assembly device described in Embodiment 1.

[0020] The excess microelements 2 are dispersed and suspended in the selected carrier solution 3, and can flow through the substrate 1 and the separator 4 under pressure, and the carrier solution in the separator 4 and the metal elastic film 8 does not contain the microelements 2, The computer 11 is programmed to control the vibration of the bending piezoelectric vibrator through the driving power supply 10. Due to the alternating bending vibration of the bending piezoelectric vibrator, the metal elastic film 8 is bent back and forth. When the metal elastic film 8 bends up and down, due to the one-way valve 9 and micro The role of the spray array 5, the fluid without the micro-element 2 can alternately flow in from the one-way valve 9 and spray out from the micro-spray array 5. After the computer 11 is programmed, the amplitude and frequency of the two bending p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com