Arm body assembling machine of hydraulic buffer hinge

A technology of hydraulic buffering and assembling machine, applied in assembling machines, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing work efficiency, inability to make wide openings, increasing the failure rate of products, etc., to improve the success rate, reduce Effects of manual assembly and pin insertion operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "inner", "middle", "left", "right" and "one" quoted in this specification are only for the convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

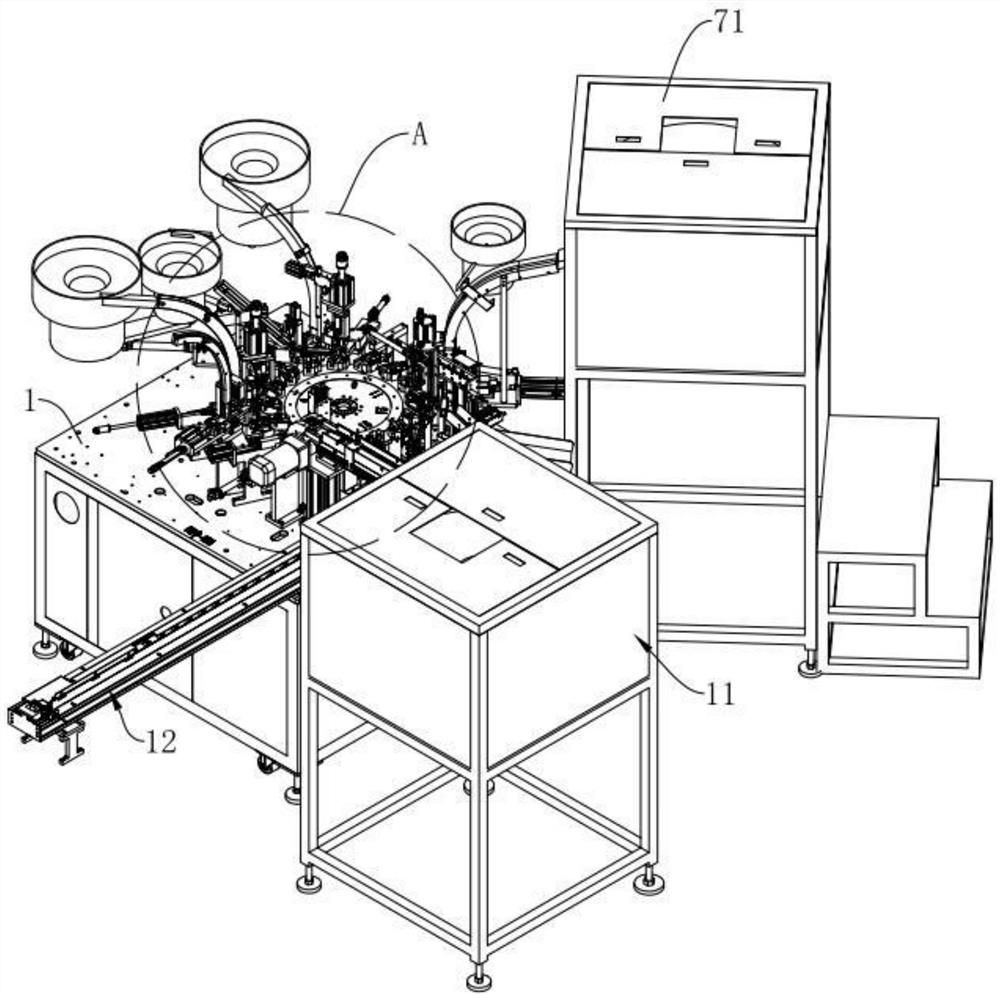

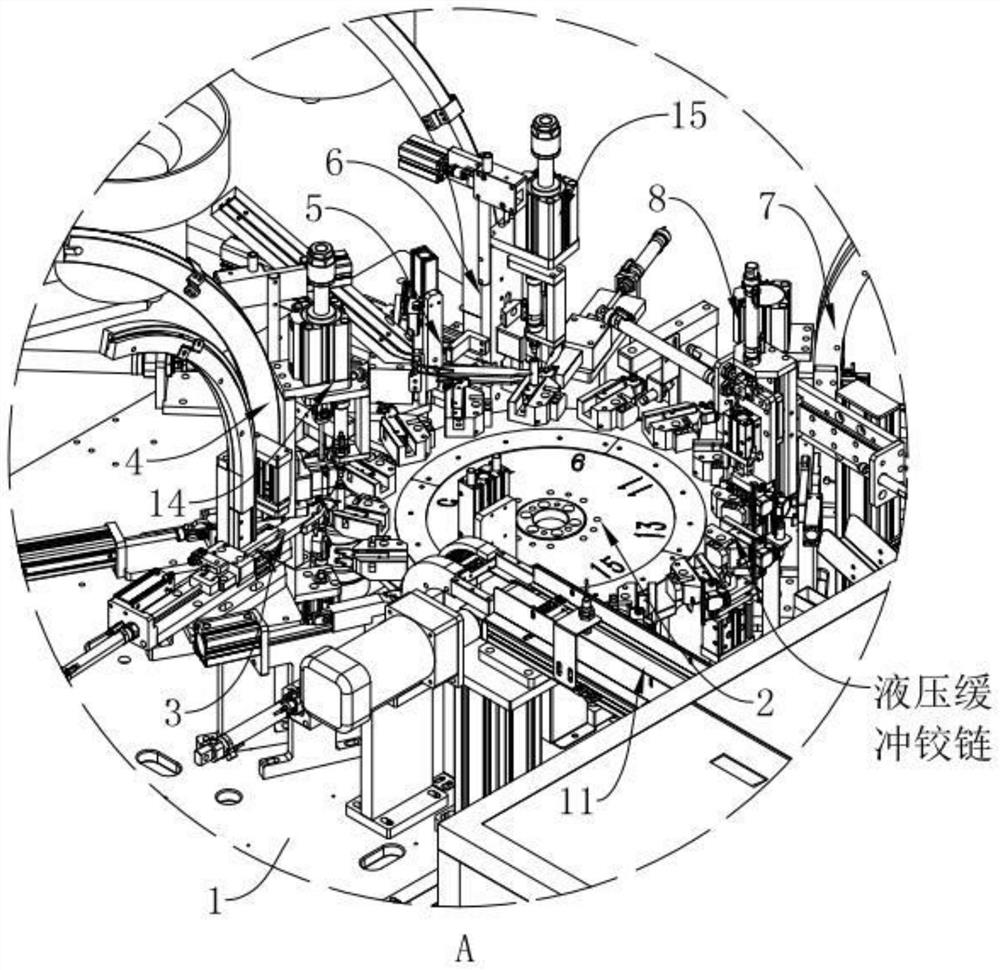

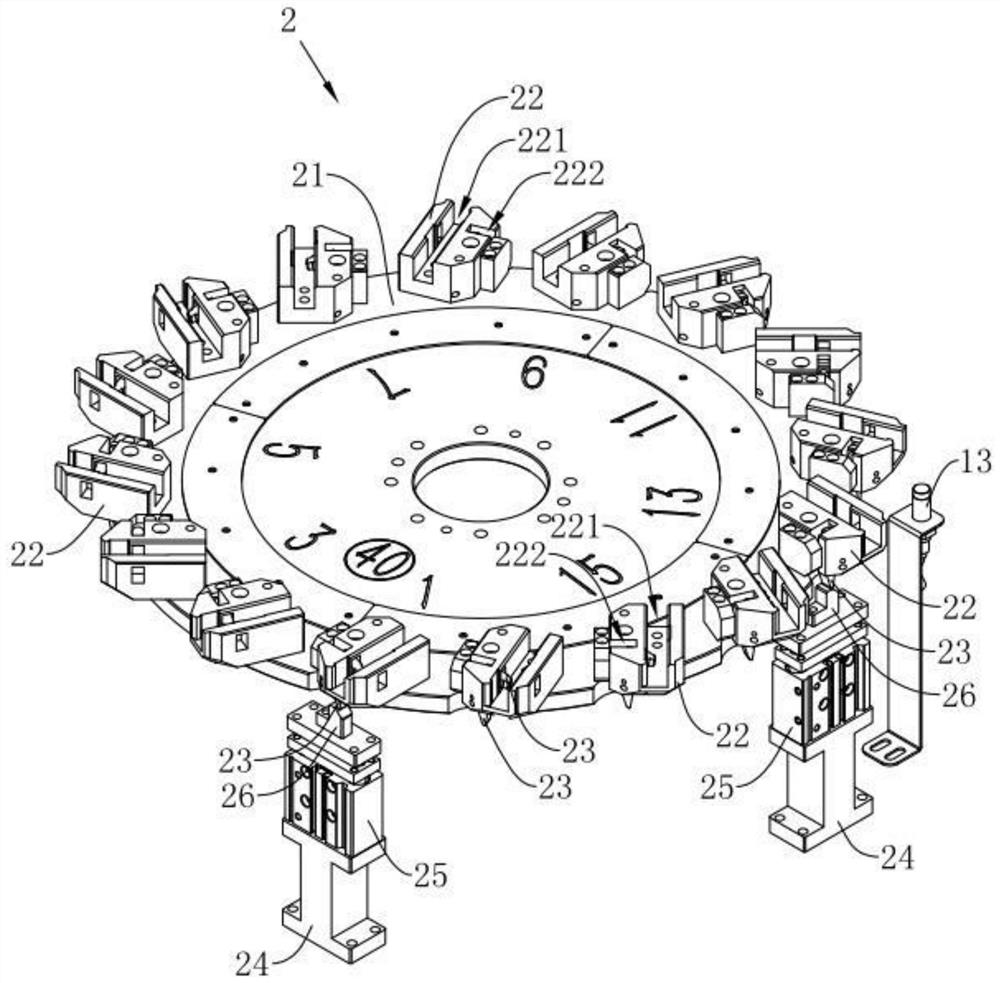

[0041] refer to figure 1 and figure 2 The shown arm body assembly machine of a hydraulic buffer hinge includes a frame 1 supported on the ground by rollers, the frame 1 is arranged in a cube, and the top surface of the frame 1 is connected with a motor through a screw lock (not shown in the figure). shown), the motor (not shown in the figure) is a deceleration servo motor, which can rotate intermittently according to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com