Numerical control pipe fitting assembly machine

A technology for assembly machines and pipe fittings, which is applied in the direction of assembly machines, positioning devices, metal processing machinery parts, etc., can solve the problems of increased installation workload, more materials consumed, and low first-time success rate, etc., and achieve saving The effect of reducing manpower and influencing factors and improving the success rate of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

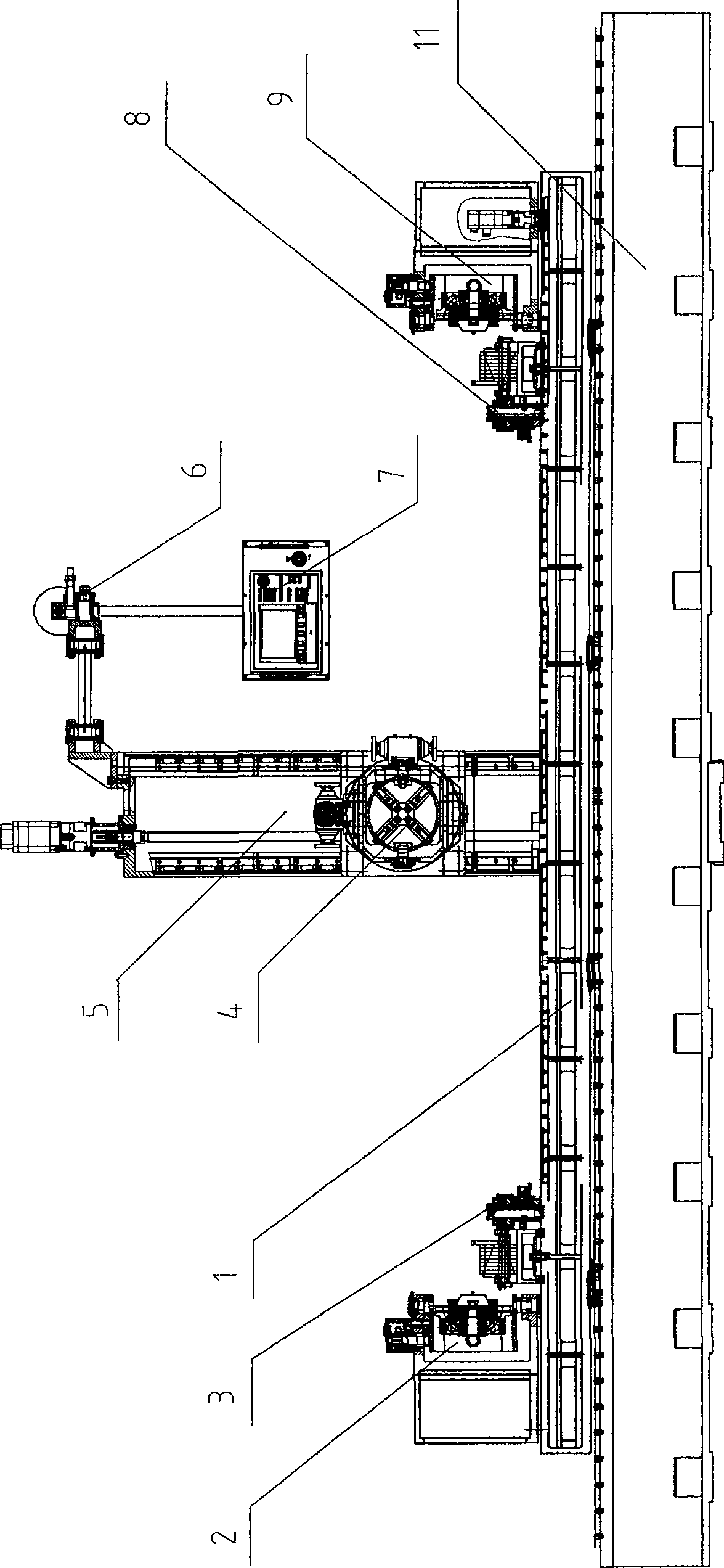

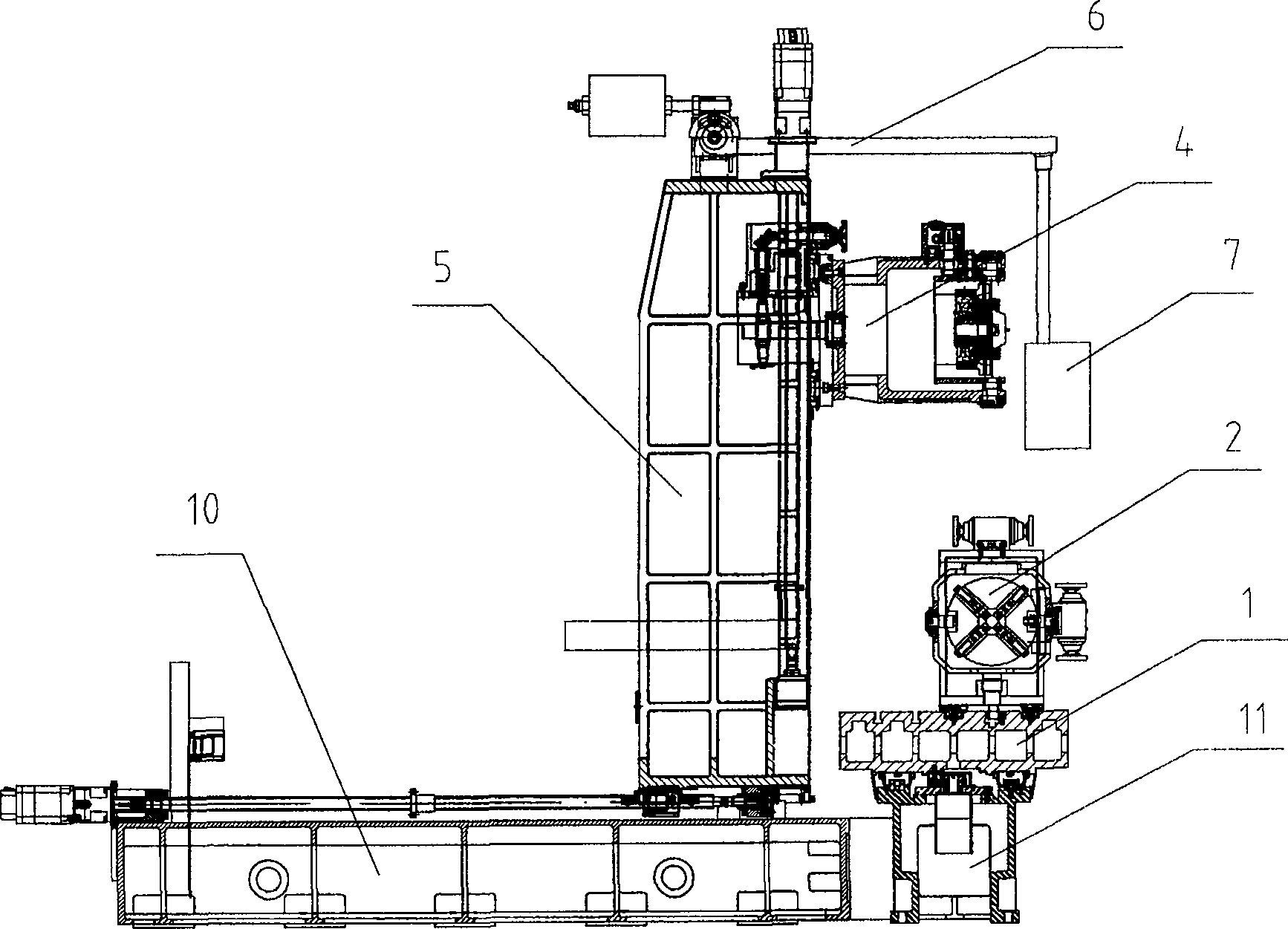

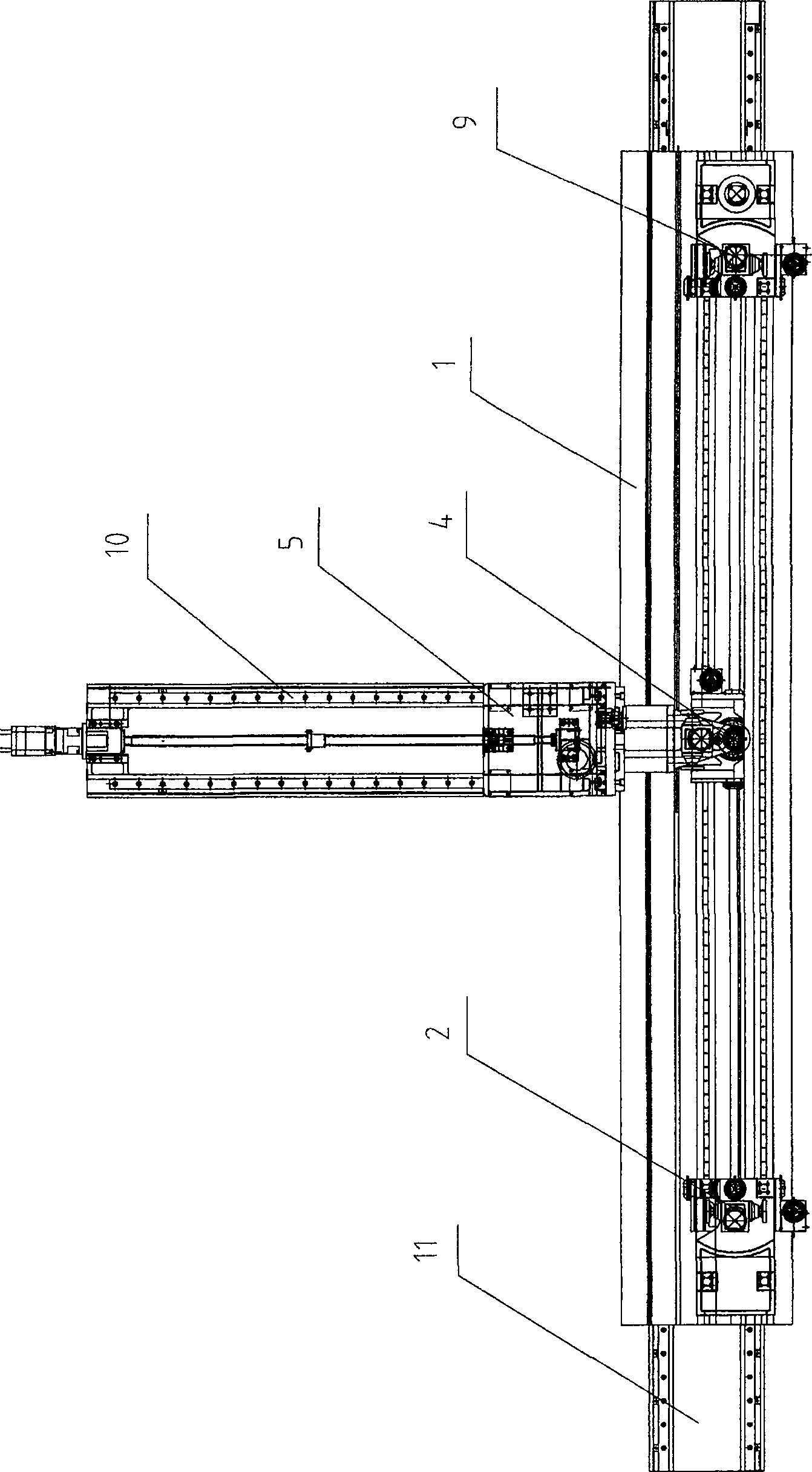

[0030] combined with figure 1 , attached figure 2 And attached image 3 As shown, the numerically controlled pipe fitting assembly machine of this embodiment includes a transverse body 10, a column 5, a vertical clamping device 4, a longitudinal body 11, a mobile workbench 1, a first horizontal clamping device 2, a second horizontal Clamping device 9, first workpiece supporting fixture 3, second workpiece supporting fixture 8, and electrical control system. The CNC pipe fitting assembly machine is a precision measuring machine tool. Its electrical control system includes an electrical control cabinet, a suspension control box 7, and electrical devices on the fuselage. The electrical control cabinet provides power control, and its input voltage is AC380V (3-ph±10%) , frequency 50Hz±1% (continuous) / 50Hz±2% (temporary); working environment conditions are: ambient temperature -5°C-40°C, temperature change rate 11°C / Min, relative humidity ≤85%, instantaneous The maximum relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com