A fiber optic connector

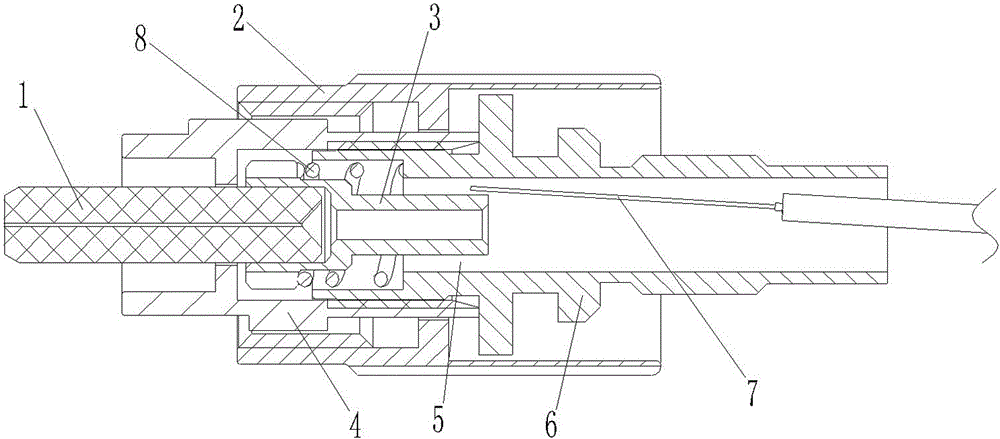

An optical fiber connector and back cover technology, which is applied in the field of optical fiber connectors, can solve the problems of low assembly efficiency, broken wire cores, and the fiber core is inserted into the rear end surface of the flange, so as to achieve the effect of improving the success rate of assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

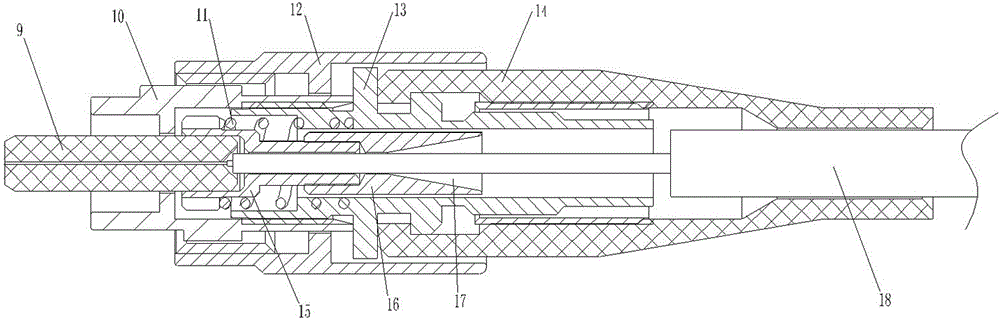

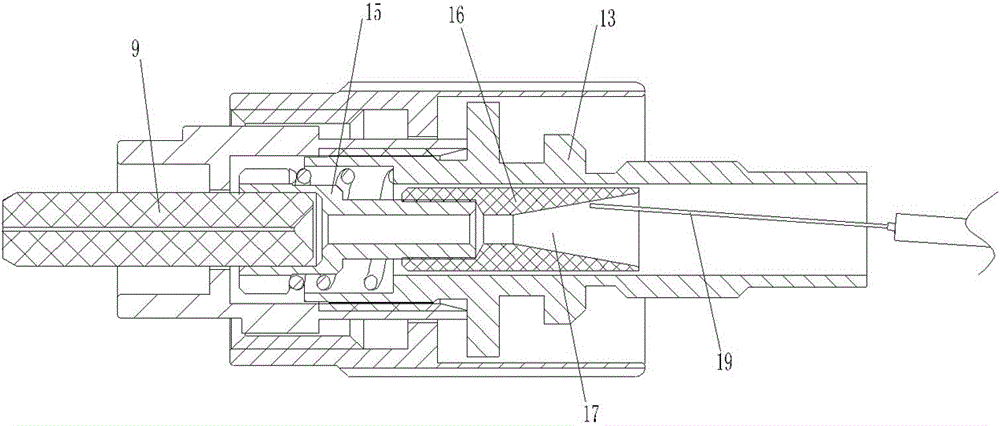

[0016] Examples of fiber optic connectors are Figure 2~3 Shown: including the front cover 10, the rear cover 13 and the flange 15 with the ferrule 9 at the front end, the front cover is screwed with the connecting nut 12, and the rear end of the flange extends into the inner hole of the rear cover. There is a radial gap between the rear end of the flange and the wall of the inner hole of the rear sleeve. The rear end of the flange is screwed with a guide structure 16. The outer end of the guide structure is located in the radial gap, and the guide structure extends into the In the inner hole of the rear sleeve, the guide structure is matched with the inner hole wall of the rear sleeve at the same time, so that the guide structure can move back and forth in the inner hole of the rear sleeve without affecting the axial movement of the flange when the connector is docked. The guide structure is provided with a guide hole 17 in which the front end communicates with the inner hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com