Method and system for cooperatively treating organic waste salt and high-salt organic wastewater by cement kiln

A technology of organic wastewater and co-processing, applied in the field of waste treatment, can solve problems such as the inability to completely eliminate the impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

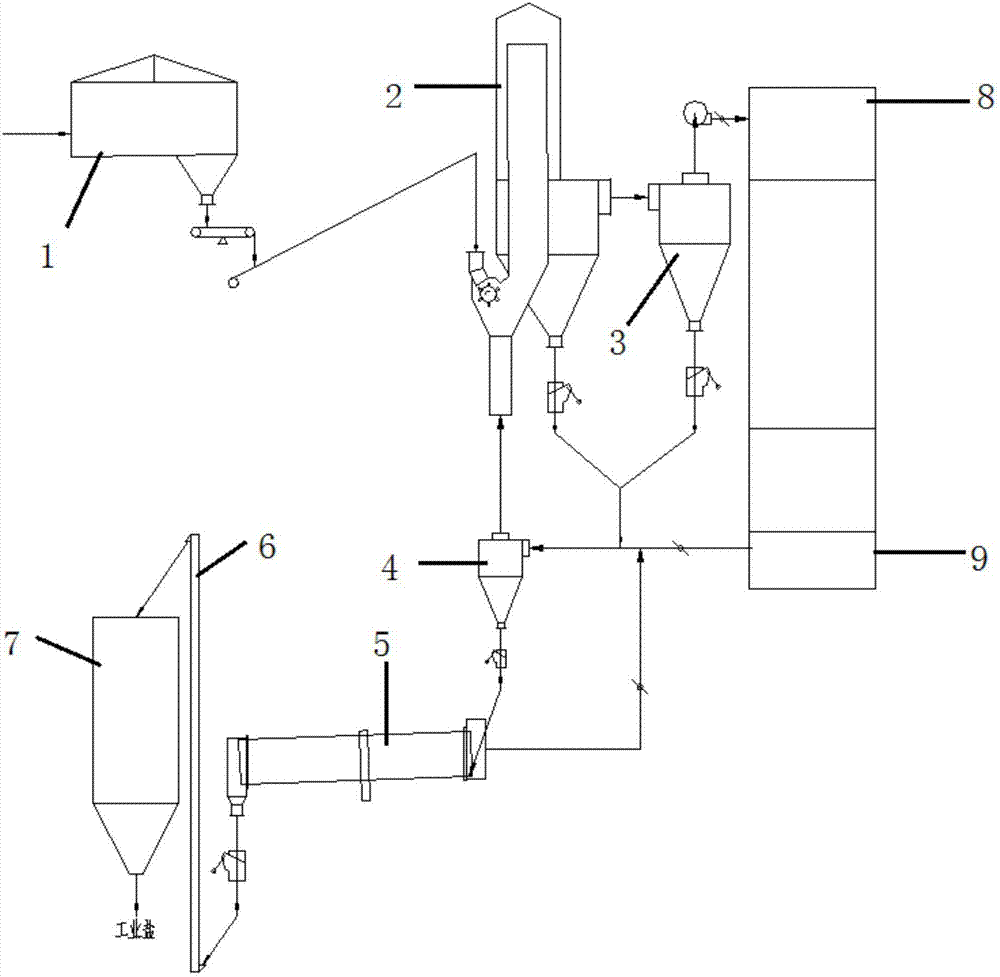

[0088] like Figure 1~3 As shown, the present invention provides a system for co-processing organic waste salt in a cement kiln, including: a cement kiln system, a first incineration device, a second incineration device 4 and a cooling recovery device;

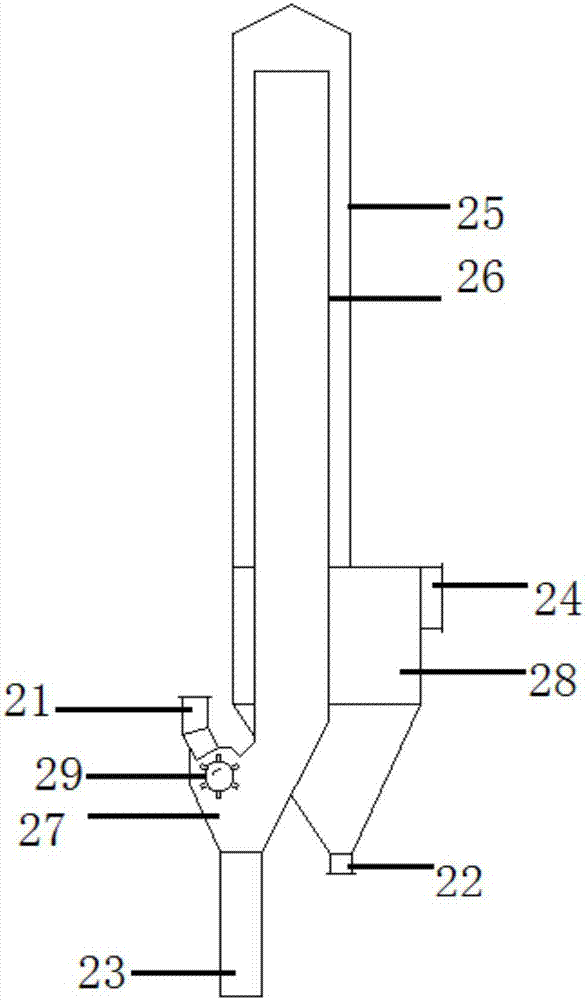

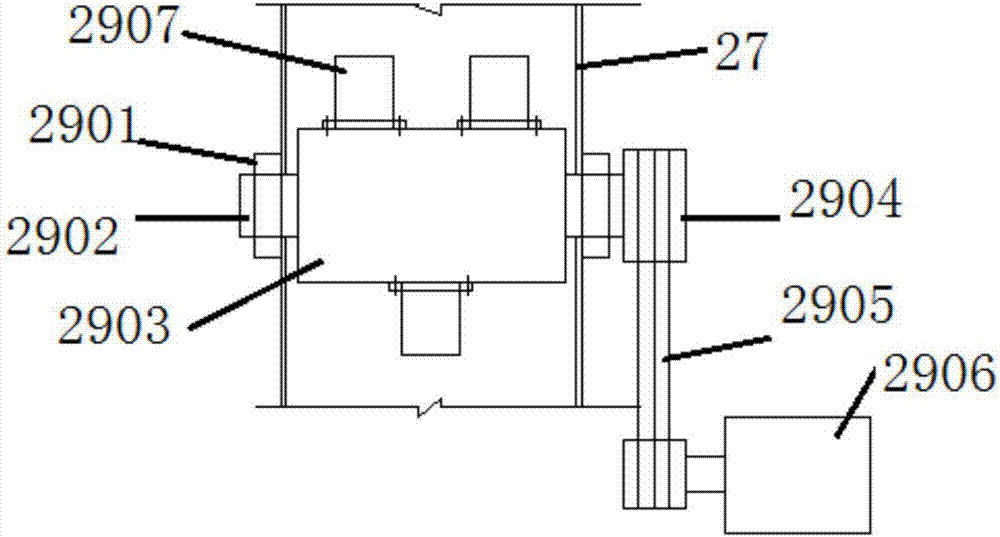

[0089] The first incineration device includes a vertical sleeve dispersing and grading drying furnace 2 and a cyclone separator 3;

[0090] The feed port of the vertical sleeve dispersing and grading drying furnace 2 is connected to the discharge port of the waste salt storage 1; the air outlet of the vertical casing dispersing and grading drying furnace 2 is connected to the cyclone separator 3 connected to the entrance;

[0091] The material outlet of the cyclone separator 3 and the discharge port of the vertical casing to disperse and classify the drying furnace 2 are connected to the inlet of the second incinerator 4;

[0092]The material outlet of the second incineration device 4 is connected with the inlet of the cooli...

Embodiment 2

[0109] Such as Figure 2-5 As shown, a cement kiln co-processing system for high-salt organic wastewater includes: a pretreatment device, a cement kiln system, a first incineration device, a second incineration device 4 and a cooling recovery device;

[0110] The pretreatment device includes a waste liquid pool 16, a deployment station 15, a sedimentation concentration pool 14, a warehouse evaporator 11 and a concentrated liquid pool 13 connected in sequence;

[0111] The first incineration device includes a vertical sleeve dispersing and grading drying furnace 2 and a cyclone separator 3;

[0112] The outlet of the concentrated solution pool 13 is connected to the feed port of the vertical casing dispersing and grading drying furnace 2; the air outlet of the vertical casing dispersing and grading drying furnace 2 is connected to the inlet of the cyclone separator 3 ;

[0113] The material outlet of the cyclone separator 3 and the discharge port of the vertical casing to dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com