A method for harmless co-processing of heavy metal sludge and organic silicon waste

A heavy metal sludge and co-processing technology, which is applied in sludge treatment, chemical instruments and methods, fixed/solidified sludge treatment, etc., can solve the problems of difficulty in recycling organic silicon waste and high cost of high-temperature solidification of heavy metal sludge. To achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

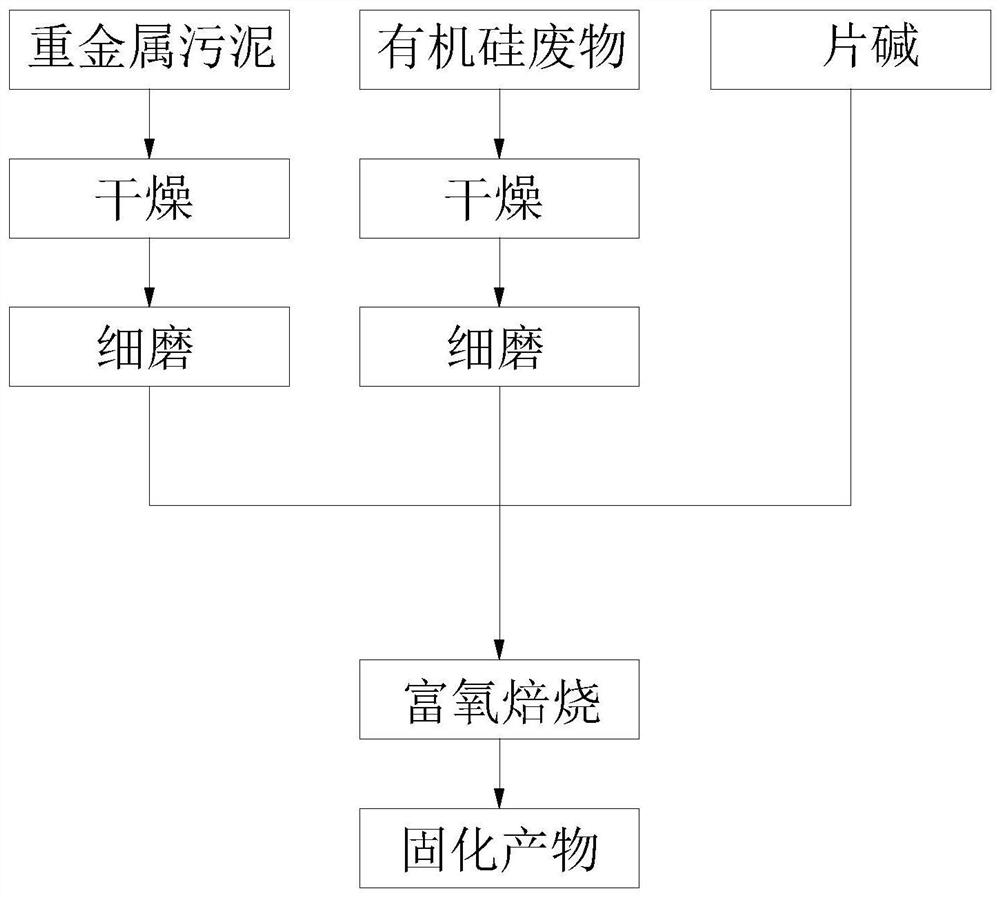

[0027] In this embodiment, zinc-containing sludge is treated as the treatment object, and waste disposal is performed by high-temperature solidification with organic silicon waste. like figure 1 As shown, the specific method is as follows:

[0028] Select zinc-containing sludge and pyrolysis residue for drying, so that the moisture content of zinc-containing sludge and pyrolysis residue is reduced from 70% and 50% to below 10% respectively; caustic soda does not need to be dried because its moisture content is lower than 5%. The zinc-containing sludge with a particle size of less than 0.55mm after grinding, the pyrolysis residue and caustic soda are uniformly mixed at a dry basis mass percentage of 45:40:15 to obtain a mixture.

[0029] One part of the mixed material is cured at a temperature of 1350° C., the curing time is 3.5 hours respectively, and the high temperature curing atmosphere is oxygen-enriched, and the oxygen concentration is 25%. After high temperature solidi...

Embodiment 2

[0035] In this example, copper-containing sludge is used as the treatment object, and waste disposal is carried out by solidifying with organic silicon waste at high temperature. The specific method is as follows:

[0036] Select copper-containing sludge and pyrolysis residue for drying, so that the moisture content of copper-containing sludge and pyrolysis residue is reduced from 75% and 50% to below 10% respectively; caustic soda does not need to be dried because its moisture content is lower than 5%. The copper-containing sludge with a particle size of less than 0.55 mm after grinding, the cracking residue and caustic soda are mixed uniformly at a dry basis mass percentage of 50:40:10. The mixed materials were respectively melted at a temperature of 1400° C., the melting time was 3 hours, and the oxygen concentration was 25%. After high-temperature solidification, it is rapidly cooled by water quenching to form silicon-based glass material B.

[0037] The vitreous body con...

Embodiment 3

[0039] In this example, nickel-containing sludge is used as the treatment object, and waste disposal is carried out by solidifying with organic silicon waste at high temperature. The specific method is as follows:

[0040] Select nickel-containing sludge and pyrolysis residue for drying, so that the moisture content of copper-containing sludge and pyrolysis residue is reduced from 76% and 50% to below 10% respectively; caustic soda does not need to be dried because its moisture content is lower than 5%. The copper-containing sludge with a particle size of less than 0.55mm after grinding, the pyrolysis residue and caustic soda are mixed uniformly at a mass percentage of 52:40:8 on a dry basis. The mixed materials were respectively melted at a temperature of 1450° C., the melting time was 3 hours, and the oxygen concentration was 25%. After high-temperature solidification, water quenching and rapid cooling form silicon-based glass material C.

[0041] The vitreous body content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com