System for treating sludge by two-phase anaerobic digestion and method

A technology of anaerobic digestion and treatment method, applied in chemical instruments and methods, special treatment targets, biological sludge treatment, etc. The effect of methane conversion and improving biogas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

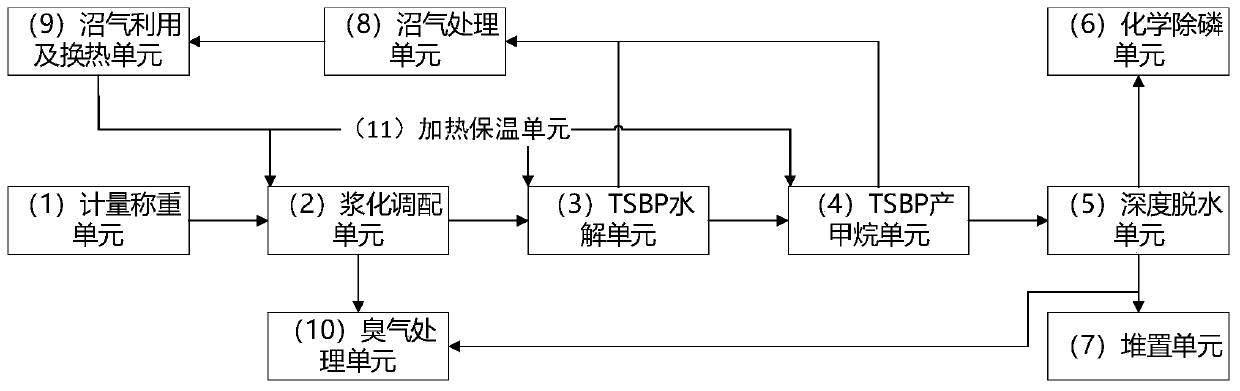

[0036] The invention discloses a system for two-phase anaerobic digestion and treatment of sludge, which is suitable for municipal sludge treatment, can effectively realize sludge production capacity, and simultaneously treats digested sludge and biogas slurry to prevent the environment from being affected. refer to figure 1 , which mainly includes:

[0037] Measuring weighing unit 1, measuring and weighing the amount of dewatered sludge and non-dewatered sludge shipped from the sewage treatment plant;

[0038] Slurry preparation unit 2 is connected to the weighing unit 1 for weighing the sludge, and mixes the dewatered sludge, non-dehydrated sludge and feces to adjust the moisture content of the sludge;

[0039] The two-phase fermentation system, that is, the sludge anaerobic fermentation reactor, is the core of the system of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com