System and method suitable for sludge coupling fire coal burning disposal

A sludge and coal-burning technology, applied in combustion methods, sludge treatment, biological sludge treatment, etc., can solve the problems of low calorific value of wet sludge and high treatment cost of self-built incineration system, achieve low moisture content, reduce The effect of improving steam consumption and dehydration performance in power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

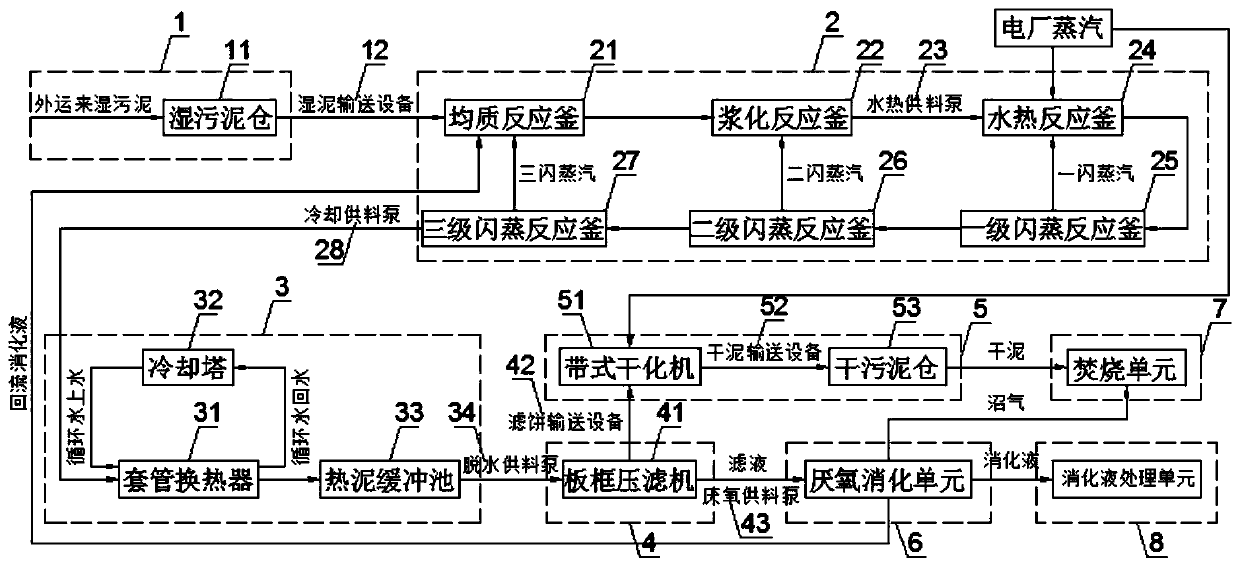

[0036] The embodiment discloses a system (hereinafter referred to as the system) suitable for sludge coupled with coal-fired incineration, which is used for hydrothermal treatment of sludge, such as figure 1 As shown, the system mainly includes a receiving and storage unit 1 , a hydrothermal unit 2 , a circulating cooling unit 3 , a dehydration unit 4 , a drying unit 5 , an anaerobic digestion unit 6 , an incineration unit 7 , and a digestive liquid treatment unit 8 .

[0037] The receiving and storage unit 1 mainly includes a wet sludge bin 11 and a wet sludge conveying device 12 . The exported wet sludge is stored in the wet sludge bin 11. The wet sludge is transported to the hydrothermal unit 2 through the wet sludge conveying equipment 12 arranged at the bottom of the wet sludge silo 11 .

[0038] The hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com