Integrated power self-supply system employing combined heat and power for centralized heating boiler house

A technology for cogeneration and central heating, which is applied in hot water central heating systems, heating systems, household heating, etc., can solve problems such as affecting the economic benefits of enterprises and restricting the development of enterprises, so as to improve the economic benefits of enterprises and society. Benefit, save money, reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

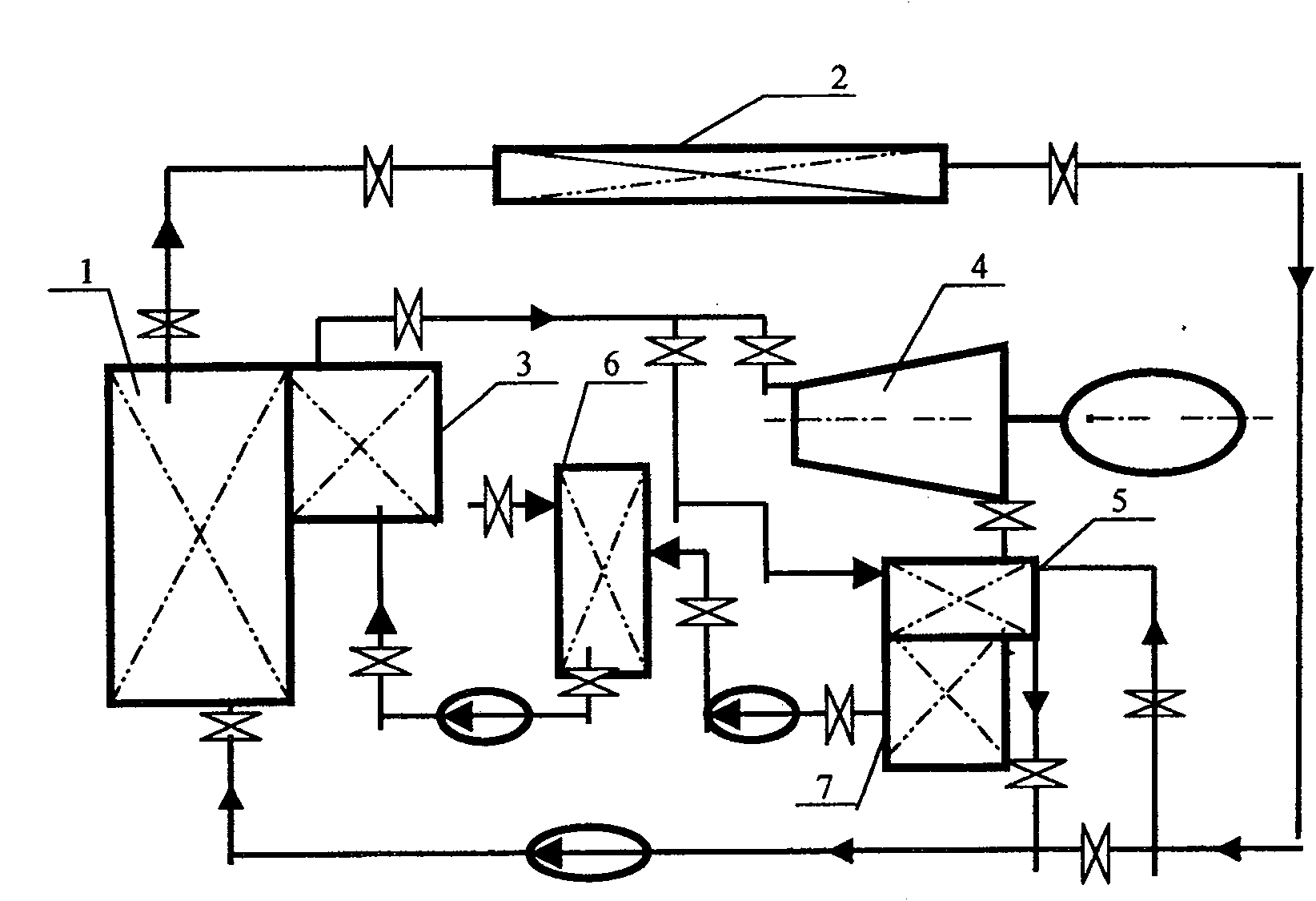

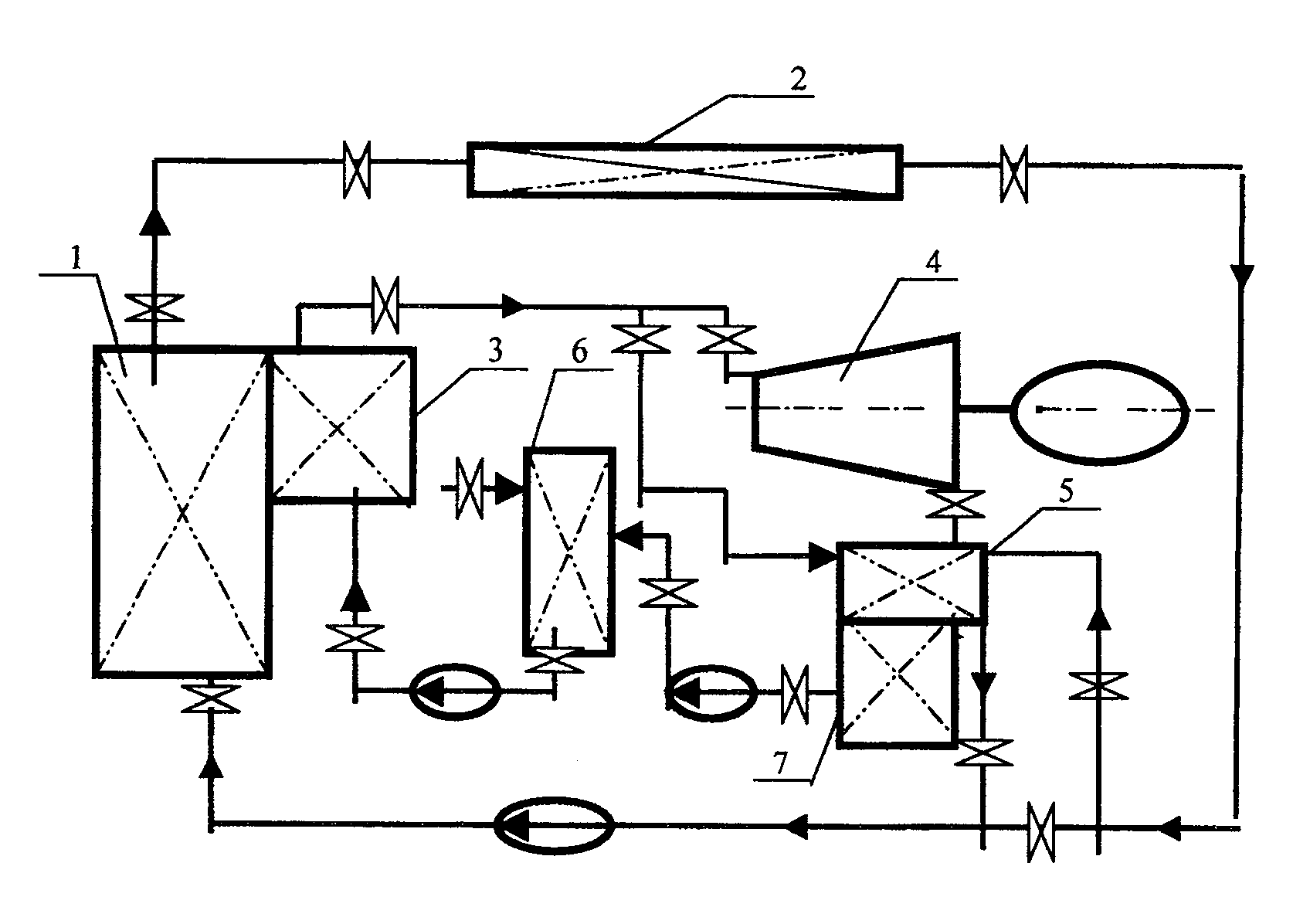

[0014] As shown in the attached figure: an intensive heat and power cogeneration power self-sufficiency system for a central heating boiler room, which is equipped with a circulating heating system composed of a hot water boiler 1, a heating user 2 and a water pump, which is the same as the prior art, here Not to repeat, the present invention is also provided with a power output system composed of steam boiler 3, steam turbine 4, heat exchanger 5, and deaerator 6. In the power output system, hot water boiler 1 is connected with steam boiler 3 through pipelines. Simple, smaller in size and less investment, the hot water boiler 1 and the steam boiler 3 in the present invention also adopt the hot water-steam cogeneration boiler, the steam boiler 3 is connected with the inlet pipe of the steam turbine through the pipeline, and the outlet pipe of the steam turbine 4 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com