Purification method of semi-finished ferrite product containing chromium and nickel

A purification method and ferrite technology are applied in the field of recycling and utilization of heavy metal ions, which can solve problems such as pollution, and achieve the effects of realizing economic value, eliminating pollution and reducing energy consumption in production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

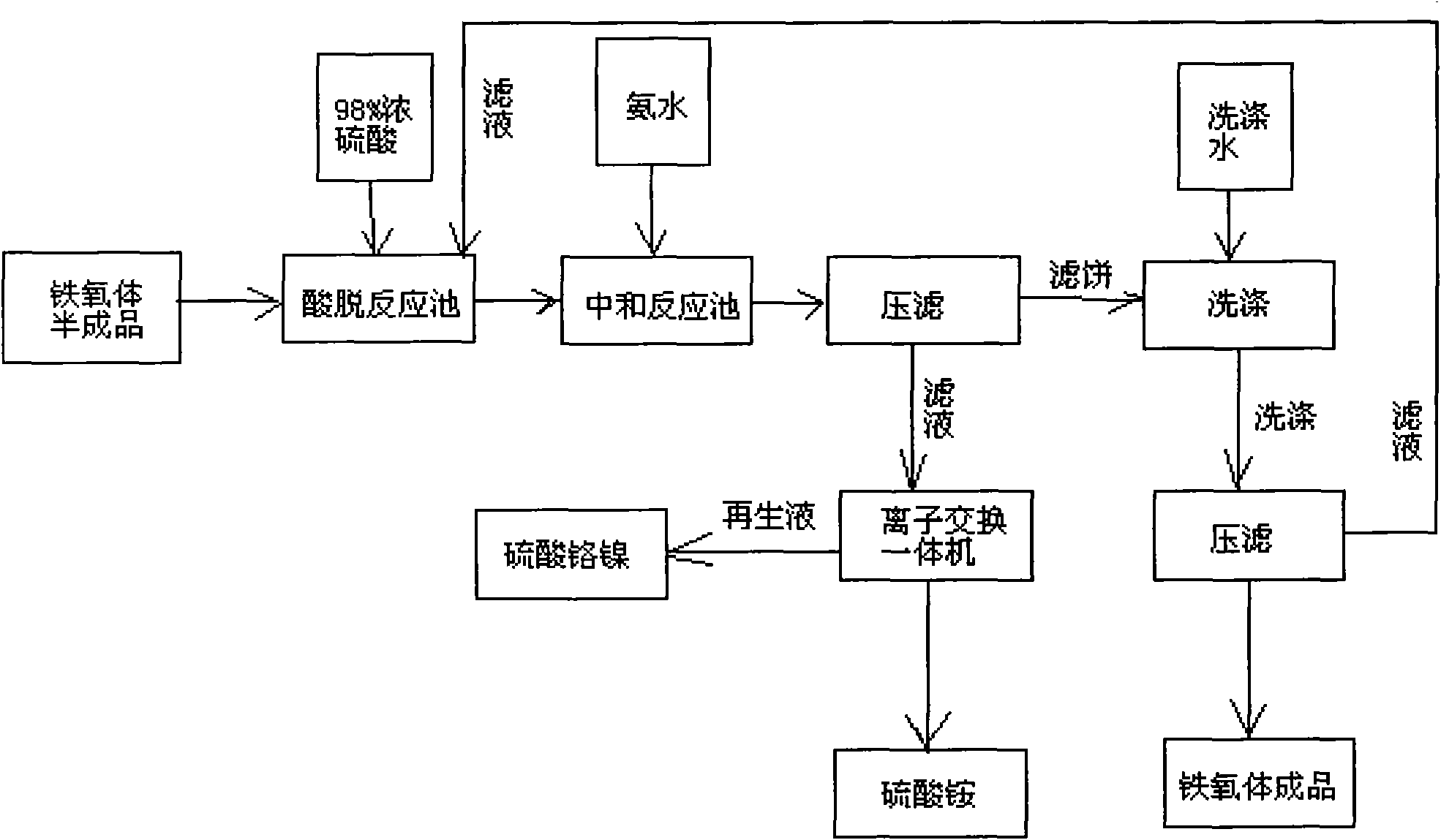

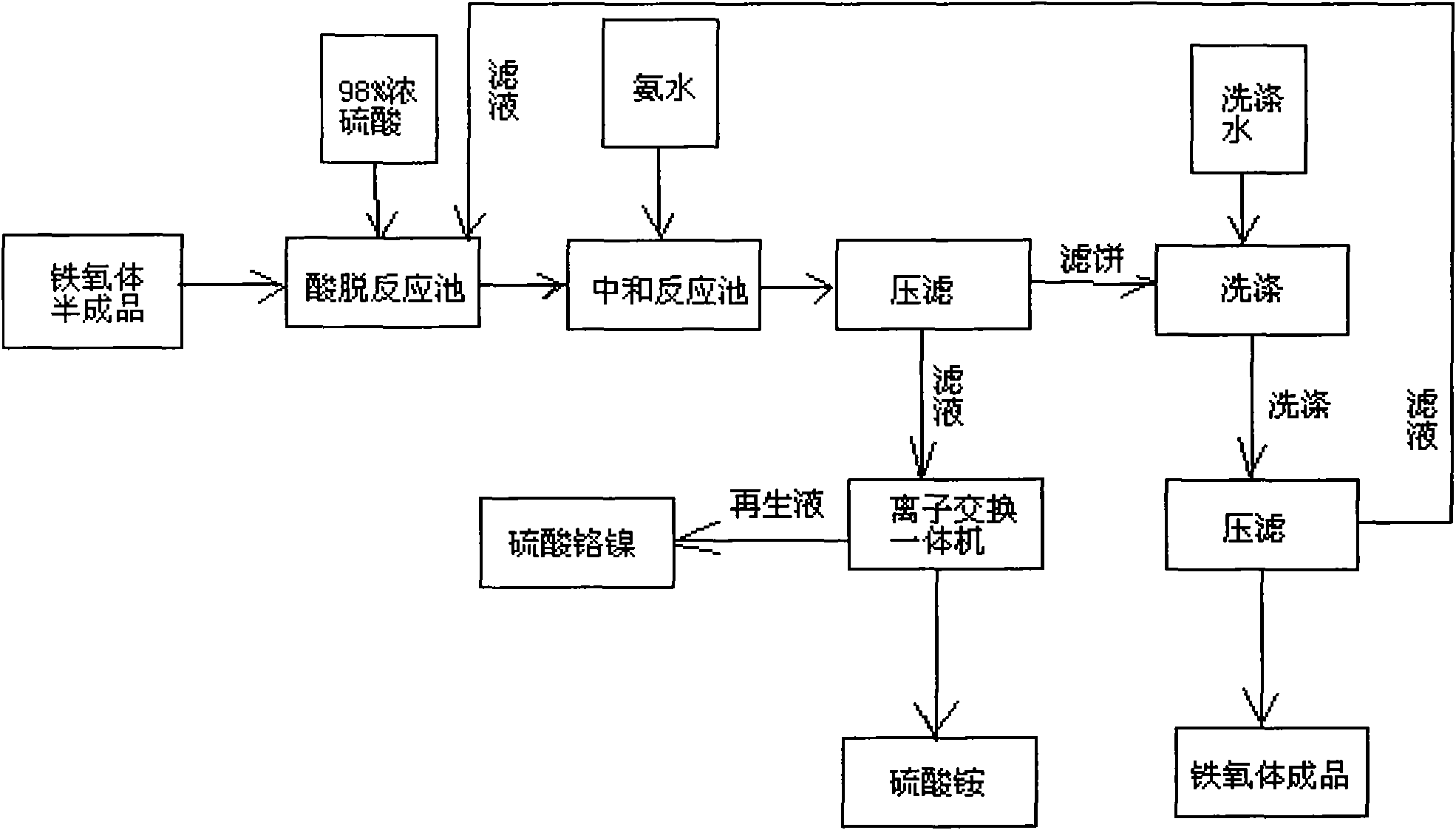

[0037] Stainless steel pickling waste water sludge, through preliminary treatment, obtains ferrite semi-finished product containing chromium and nickel, wherein content (mass content) is roughly as follows: Fe 2 o 3 80-85%, Cr 2 o 3 10-15%, NiO 1-4%.

[0038] (1) Acid leaching process: Put 3 tons of ferrite semi-finished products containing chromium and nickel (solid content is about 30%) into the acid leaching reaction tank every day, then add 98% concentrated sulfuric acid, about 1.8 tons per day, until the acid leaching In the reaction tank, adjust the PH value to 2.8 and let it stand still; soak it fully so that Fe, Cr, and Ni metals all exist in the acid solution in an ion state;

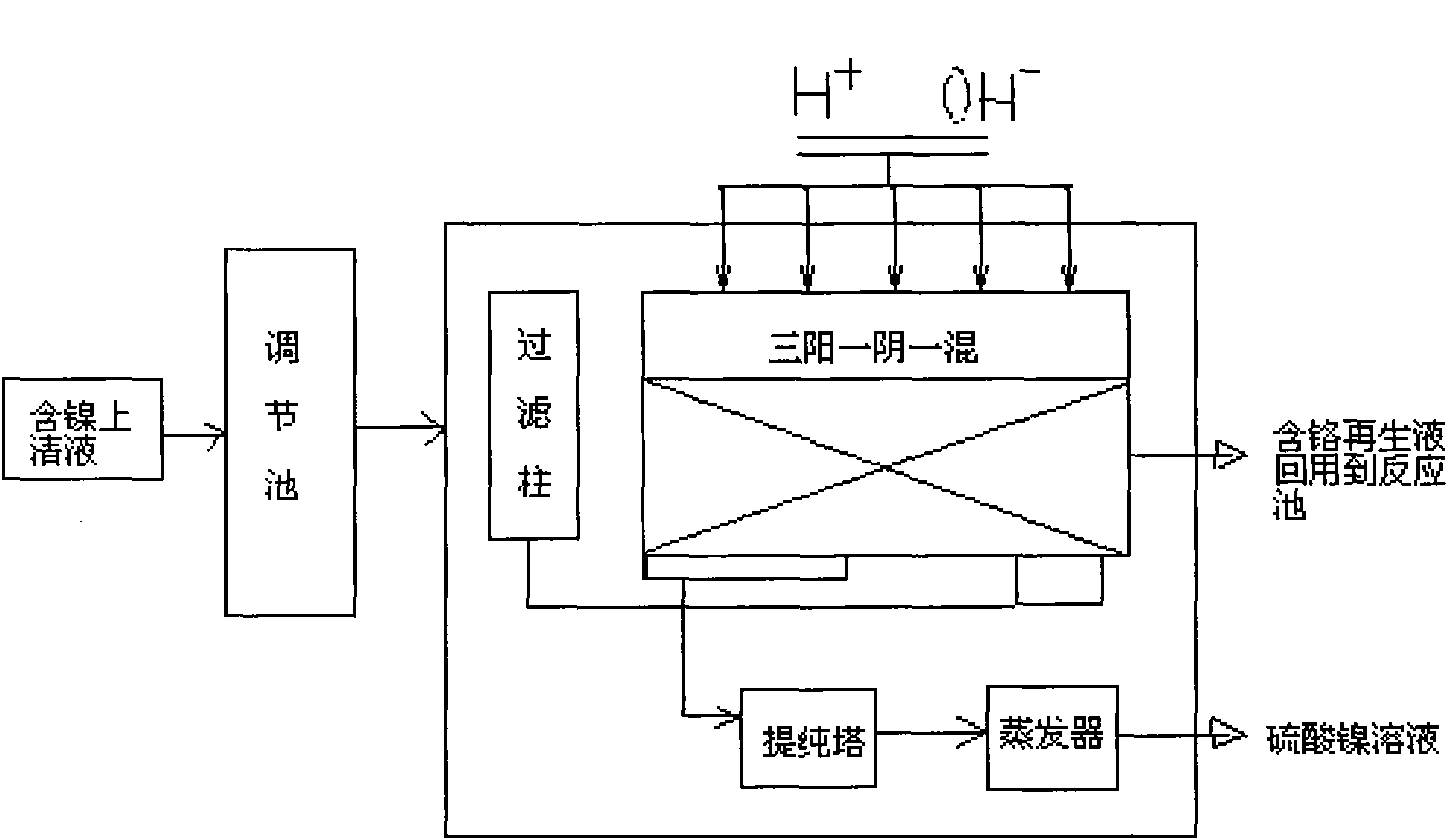

[0039] (2) Precipitation process: the solution through the acid leaching process is sent to the neutralization reaction tank, and adding mass concentration in the neutralization reaction tank is 28% ammoniacal liquor, 5 tons per day, to adjust the pH value of the solution in the neutraliza...

Embodiment 2

[0045] Test according to the process carried out in embodiment 1,

[0046] In engineering test one, the acid leaching reaction pool was adjusted to 2.5 in pH value,

[0047] In engineering test one, the acid leaching reaction pool was adjusted to 2.6 in pH value,

[0048] In engineering test one, the acid leaching reaction pool was adjusted to 2.7 pH value,

[0049] Finally, multi-component ferrite can be obtained, and the components are as follows:

[0050]

[0051] The quality of the ferrite prepared in the present invention meets the national industrial level requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com