Method for extracting chromated nickel from low-grade stainless steel sludge by using stainless steel acid-washing waste mother liquor

A stainless steel, low-grade technology, applied in the field of chemical treatment, can solve the problems of low utilization rate of equipment, high energy consumption, poor economic benefits, etc., to achieve significant economic effects, reduce environmental pollution, and realize the effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

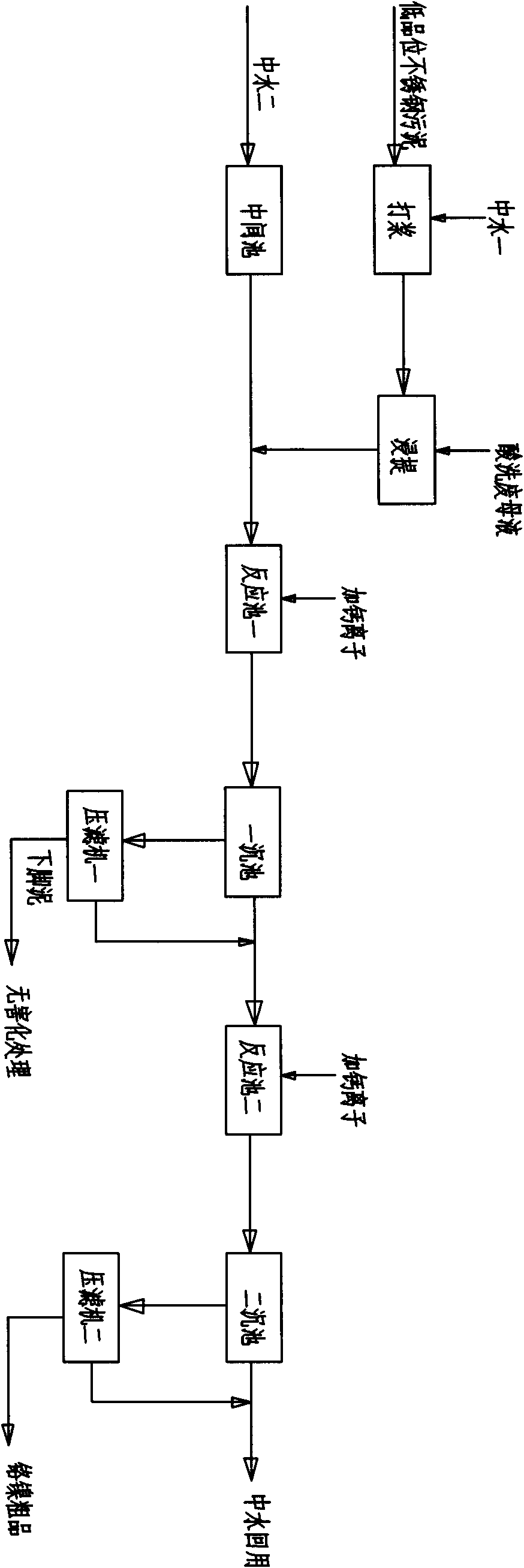

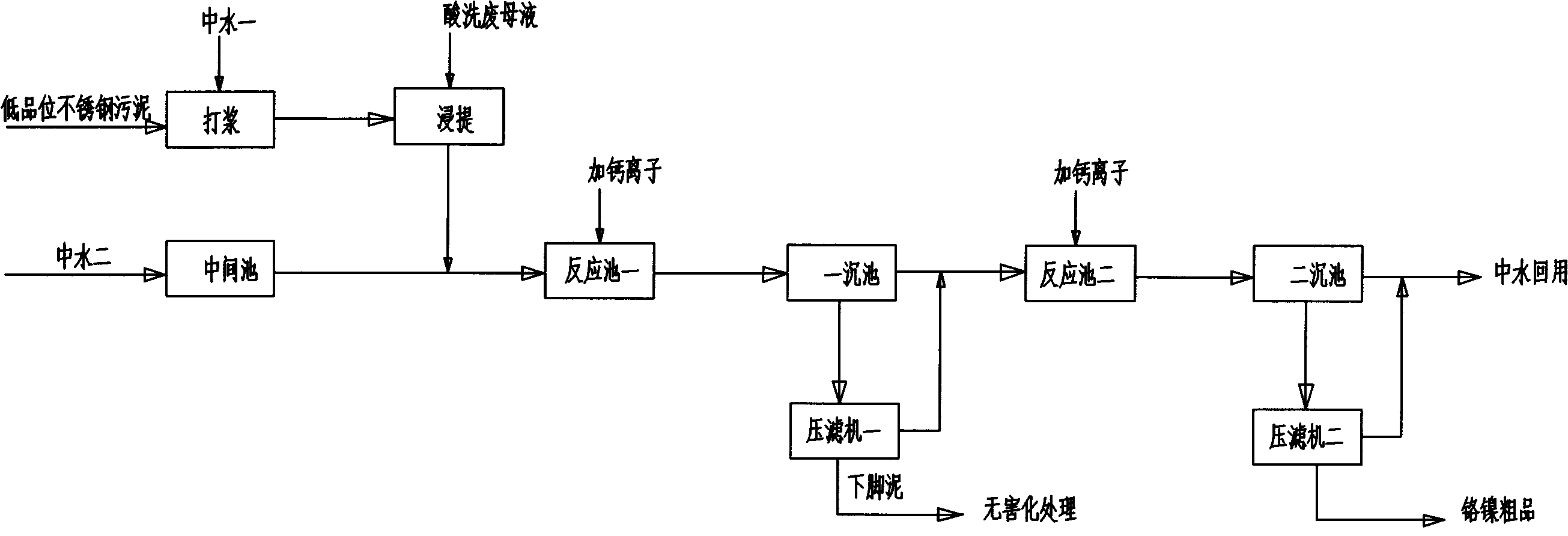

[0020] Get low-grade stainless steel sludge 1000kg, Ni1.4% wherein, Cr 2%, according to figure 1 The process step is to use reclaimed water first for beating treatment, and the low-grade stainless steel sludge and reclaimed water are completely mixed evenly, wherein the mixing mass ratio of reclaimed water and low-grade stainless steel sludge is 4:1, and then go to beating treatment Add pickling waste mother liquor to the finished slurry for extraction treatment, and consume 660kg of scrap mother liquor through this process until the pH in the slurry is 2.0; then add reclaimed water to the intermediate pool for standby, and then put the waste in the intermediate pool Reclaimed water 2 is mixed with the slurry after leaching treatment, reacts in reaction tank 1, and adds calcium hydroxide in reaction tank 1 until the pH in reaction tank 1 is 3.5, then stops adding calcium hydroxide; The amount of reclaimed water 2 is ten times that of reclaimed water 1, about 44 tons; after the...

Embodiment 2

[0022] By the same method of embodiment 1, the calcium hydroxide wherein is replaced with calcium oxide, the low-grade stainless steel sludge 1000kg that is used, Ni 2.1% wherein, Cr 2.2%, consume scrap mother liquor 660kg through this process treatment, the amount of reclaimed water 44 tons, produced 766kg of waste sludge, of which Ni 0.45%, Cr 0.90%, and produced 234kg of chrome-nickel crude product, of which Ni 7.5%, Cr 6.46%.

[0023] Because the price of ore slime or stainless steel sludge with different nickel content is quite different when they are reused for the second time, so by the treatment process of the present invention, the problem of no use value or high cost of the general nickel treatment process can be solved. Effectively realize the double benefits of economy and environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com