Baking-free brick and method for utilizing silicon sludge formed in polycrystalline silicon production to manufacture baking-free brick

A non-burning brick and polysilicon technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of high cost of silicon mud treatment, and achieve the effects of simple production, reduced pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

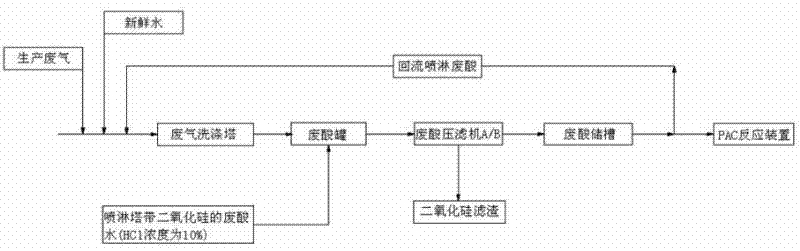

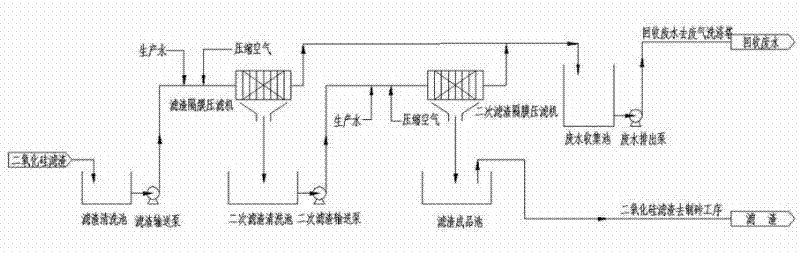

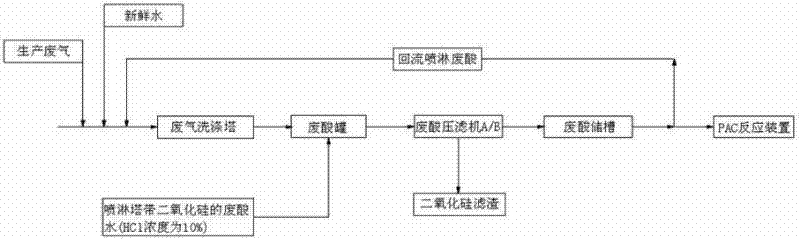

[0030] Such as figure 1 and figure 2 As shown, this embodiment is realized through the following steps:

[0031] A. In the polysilicon production process, the silicon mud formed by waste gas and waste liquid treatment is dechlorinated, so that the chlorine content in the silicon mud is less than 0.5%, and it is 0.45%, and then filtered to make the water content 10%; polysilicon production process Among them, the method of waste gas and waste liquid treatment for the formed silica mud is: (1) send the waste gas and waste liquid into the waste gas scrubber, and after being washed by the spray liquid at the top of the scrubber, the formed low-concentration hydrochloric acid and bismuth Silicon oxide is sent into the leaching tank, in which hydrogen, nitrogen, a very small amount of hydrogen chloride gas and chlorosilane gas are emptied after subsequent treatment; (2) The low-concentration hydrochloric acid in the rinsing tank is sent to the filter press, and the hydrochloric a...

Embodiment 2

[0036] Such as figure 1 and figure 2 As shown, this embodiment is realized through the following steps:

[0037] 1. Remove chlorine from silicon mud formed by waste gas and waste liquid treatment in the polysilicon production process, so that the chlorine content in the silicon mud is less than 0.5%, which is 0.48%, and then filter to make the water content 20%; polysilicon During the production process, the method of waste gas and waste liquid treatment for the formed silica mud is: (1) send the waste gas and waste liquid into the waste gas scrubber, and after being washed by the spray liquid at the top of the scrubber, the low-concentration hydrochloric acid formed and silicon dioxide are sent into the leaching tank, in which hydrogen, nitrogen, a very small amount of hydrogen chloride gas and chlorosilane gas are emptied after subsequent treatment; (2) the low-concentration hydrochloric acid in the rinsing tank is sent to the filter press, Separation and filtration of hy...

Embodiment 3

[0042] Such as figure 1 and figure 2 As shown, this embodiment is realized through the following steps:

[0043] 1. Remove chlorine from silicon mud formed by waste gas and waste liquid treatment in the polysilicon production process, so that the chlorine content in the silicon mud is less than 0.5%, which is 0.46%, and then filter to make the water content 35%; polysilicon During the production process, the method of waste gas and waste liquid treatment for the formed silica mud is: (1) send the waste gas and waste liquid into the waste gas scrubber, and after being washed by the spray liquid at the top of the scrubber, the low-concentration hydrochloric acid formed and silicon dioxide are sent into the leaching tank, in which hydrogen, nitrogen, a very small amount of hydrogen chloride gas and chlorosilane gas are evacuated after subsequent treatment; (2) the low-concentration hydrochloric acid in the rinsing tank is sent to the filter press, Separation and filtration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com