Method for comprehensively utilizing residual tailings after extracting precious metals from acid pickling sludge

A technology for pickling sludge and precious metals, applied in the directions of non-metallic elements, chemical instruments and methods, sulfur compounds, etc., can solve the problems of living environment hazards, dangerous solid waste of tailings, cure the symptoms but not the root cause, and achieve environmental protection, reduce The effect of tailings discharge and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

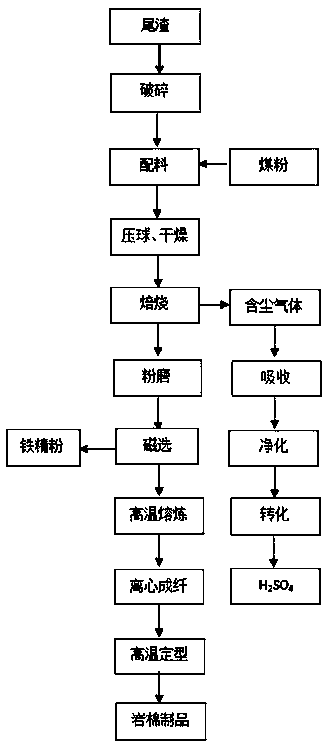

Image

Examples

Embodiment 1

[0028] The present invention comprehensively utilizes the method for remaining tailings after pickling sludge is extracted precious metal, and its steps are:

[0029] (1) Crushing: Pour the tailings into the crusher for crushing to 8 meshes; the tailings components are: Si 16.3%, Fe 15.1%, Ca 3.0%, Al 4.7%, Mg 4.8%, S 5.8%, Ni 0.72%, H 2 O 2.3%;

[0030] (2) Batching, briquetting and drying: Batch the crushed tailings and carbon powder, and mix them evenly in a large mixer, then briquette them with a briquetting machine, and then put them into a dryer at a temperature of 150°C Under drying, tailings pellets are obtained, the size of the pellets is ?20-30mm; the mass ratio of tailings and carbon powder ingredients is 4:1;

[0031] (3) Roasting: put the tailings pellets into the rotary kiln for roasting, and obtain SO after roasting 2 Smoke gas and slag; the roasting temperature is 800°C, and the roasting time is 60 minutes; after the roasting is completed, without opening th...

Embodiment 2

[0039] The present invention comprehensively utilizes the method for remaining tailings after pickling sludge is extracted precious metal, and its steps are:

[0040] (1) Crushing: Pour the tailings into the crusher for crushing to 9 meshes; the tailings components are: Si 14.3%, Fe 8.7%, Ca4.7%, Al 5.6%, Mg 7.1%, S 4.7%, Ni 0.64%, H 2 O 2.7%;

[0041] (2) Batching, briquetting and drying: Batch the crushed tailings and carbon powder, and mix them evenly in a large mixer, then briquette them with a briquetting machine, and then put them into a dryer at a temperature of 150°C Under drying, tailings pellets are obtained, the size of the pellets is ?20-30mm; the mass ratio of tailings and carbon powder ingredients is 4.5:1;

[0042] (3) Roasting: put the tailings pellets into the rotary kiln for roasting, and obtain SO after roasting 2 Smoke gas and slag; the roasting temperature is 850°C and the roasting time is 75min. After the roasting is completed, without opening the doo...

Embodiment 3

[0050] The present invention comprehensively utilizes the method for remaining tailings after pickling sludge is extracted precious metal, and its steps are:

[0051] (1) Crushing: Pour the tailings into the jaw crusher for crushing to 10 meshes; the composition of the tailings is: Si 15.6%, Fe 8.3%, Ca5.2%, Al 6.1%, Mg 4.3%, S 4.2 %, Ni 0.74%, H 2 O 2.0%;

[0052] (2) Batching, briquetting and drying: Batch the crushed tailings and carbon powder, and mix them evenly in a large mixer, then briquette them with a briquetting machine, and then put them into a dryer at a temperature of 150°C Under drying, tailings pellets are obtained, the size of the pellets is ?20-30mm; the mass ratio of tailings and carbon powder ingredients is 5:1;

[0053] (3) Roasting: put the tailings pellets into the rotary kiln for roasting, and obtain SO after roasting 2 Smoke gas and slag; the roasting temperature is 900°C, and the roasting time is 90 minutes; after the roasting is completed, without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com