Solid-liquid separation process for drilled pile waste mud

A waste mud, solid-liquid separation technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of not reducing the total amount of mud discharge, pollution sites and pollution range, etc., to achieve good flocculation effect and low cost , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

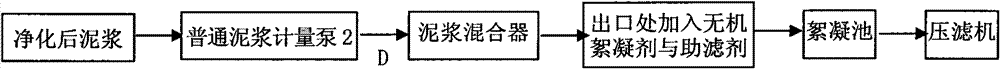

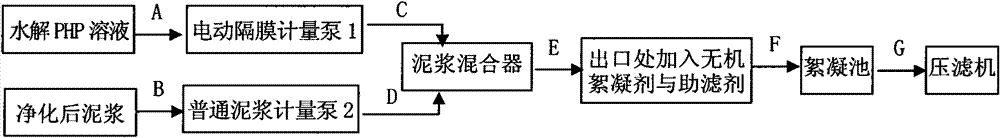

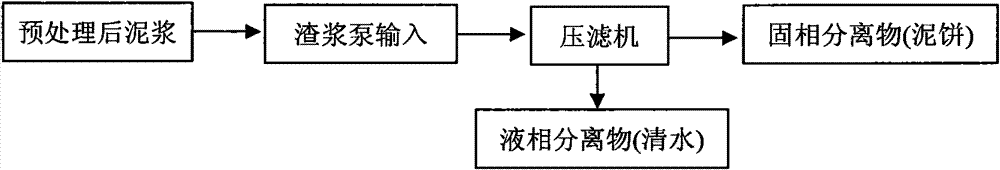

[0013] Such as figure 1 , figure 2 As shown, the first embodiment of the solid-liquid separation process for bored pile waste mud provided by the present invention includes A, collecting bored pile waste mud and purifying treatment; B, carrying out inorganic flocculation treatment to the purified mud; After flocculation, the mud uses quicklime powder as a filter aid for filter aid treatment; D. Solid-liquid separation is performed on the mud after filter aid treatment. The concrete implementation of above-mentioned steps can adopt following mode:

[0014] Step A, mud purification

[0015] The effect of mud purification can be achieved by any one of the three methods of natural sedimentation of mud, installation of steel mesh at the inlet of the mud pump, and sand removal by a desander, or all combinations of the three methods. The purpose: to adjust mud performance indicators through mud purification, The mud that meets the requirements of hole formation is recycled to red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com