Method for treating high-concentration sewage generated in waste oil regeneration process

A technology for the regeneration and treatment of waste oil, which is used in water/sewage treatment, heating water/sewage treatment, degassed water/sewage treatment, etc. It can solve the problems of increasing the amount of sewage in the park and the difficulty of treatment, and the inability to effectively treat sewage. , to reduce the CoD value and increase the Bod5/Cod effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

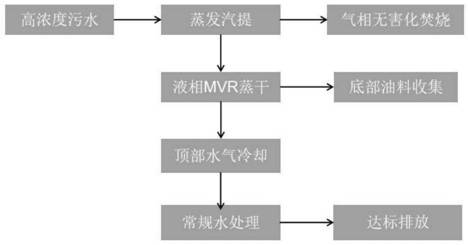

[0015] The present invention proposes a new high-concentration sewage treatment method, first introducing a COD above 200,000, BOD5 / COD <0.3. High concentration sewage is introduced into the evaporated vapor casing, and the steam flow rate is increased by heating, such as nitrogen, and cools the return flow rate. After sufficient stripping IH, aqueous phase was pumped into the bottom of the MVR evaporator, water was evaporated to dryness after oil collected, concentrated sewage collection tank to a low concentration vapor After cooling, the detection CoD less than 10000, B / C is greater than 0.6, the aqueous phase Low concentration sewage cans are pumped to the factory supporting conventional sewage treatment plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com