A method for controlling the crystallization phase of molten titanium slag

A titanium slag and melting technology, which is applied in the fields of metallurgical technology and mineral resource processing, can solve the problems of unfavorable crystallization phase for titanium upgrading, low monomer dissociation degree, and difficult removal, etc., to achieve large grain size, titanium slag The effect of quality improvement and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) According to the mass percentage, the composition of the titanium slag is adjusted to be TiO 2 52%, MgO 7%, Al 2 o 3 8%, graphite 5.2%; the titanium slag also contains FeO x 4%, SiO 2 15.9%, CaO 7.9%;

[0055] (2) Use the titanium slag regulated in step (1) as raw material, heat it to 1600°C for high temperature melting, keep it warm for 1.8h, then cool it down to 1400°C at a rate of 10°C / min, water cooling and quenching to obtain crystallization and melting titanium slag .

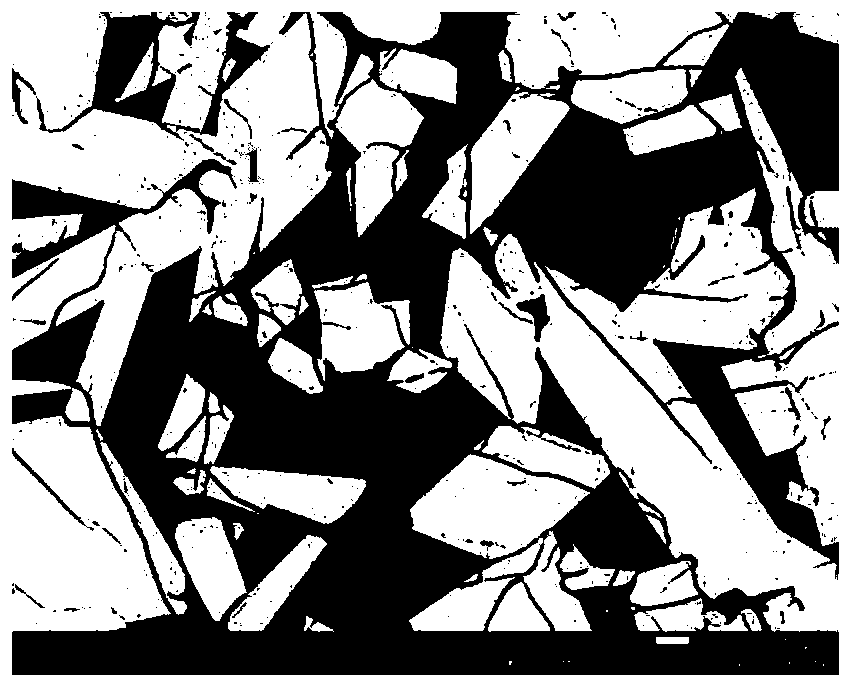

[0056] The morphology of the molten titanium slag was observed under a scanning electron microscope, such as figure 1 As shown, the slag only contains two phases of glass phase and black titanite, black titanite is the only titanium-rich phase, the structure is compact, and the interface with the glass phase is regular and round, and the weighted average particle size of black titanite is 57 μm. Using EDS to test the chemical composition of the titanium-rich phase of the molten titaniu...

Embodiment 2

[0059] (1) According to the mass percentage, the composition of the titanium slag is adjusted to be TiO 2 52%, MgO 14%, Al 2 o 3 12%, graphite 4.2%; the titanium slag also contains FeO x 5%, SiO 2 8.5%, CaO 4.3%;

[0060] (2) Using the titanium slag regulated in step (1) as raw material, heat it to 1600°C for high temperature melting, keep it warm for 0.5h, then cool it down to 1400°C at a rate of 15°C / min, water cooling and quenching to obtain crystallization and melting titanium slag .

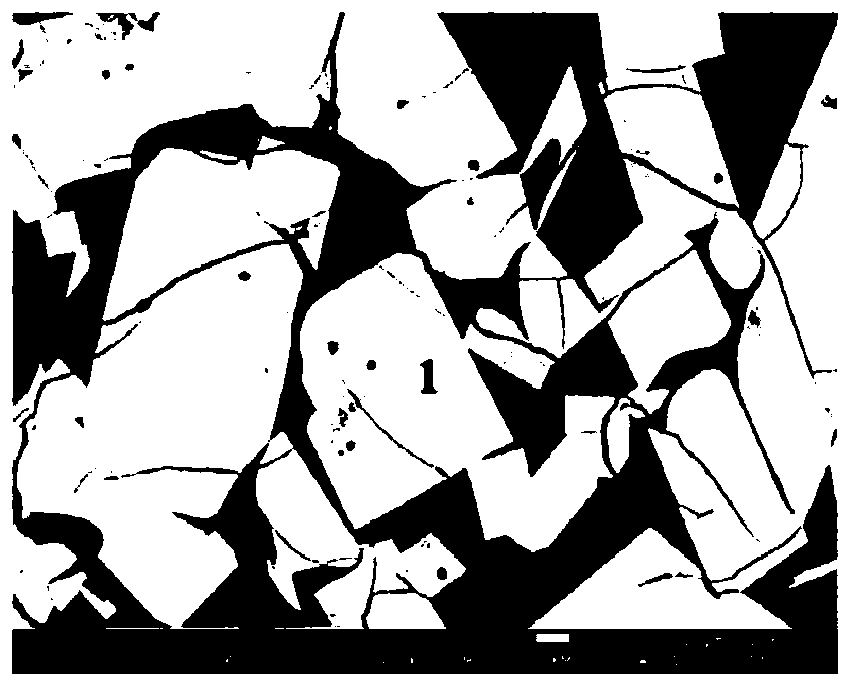

[0061] The morphology of the molten titanium slag was observed under a scanning electron microscope, such as figure 2 As shown, the slag only contains two phases of glass phase and black titanite, and black titanite is the only titanium-rich phase with a compact structure, and the interface with the glass phase is regular and round. The weighted average particle size of black titanite is 76 μm. Using EDS to test the chemical composition of the titanium-rich phase of the molten tita...

Embodiment 3

[0064] (1) According to the mass percentage, the composition of the titanium slag is adjusted to be TiO 2 60%, MgO 6%, Al 2 o 3 5%, graphite 4%; the titanium slag also contains FeO x 8%, SiO 2 11.3%, CaO 5.7%;

[0065] (2) Use the titanium slag regulated in step (1) as raw material, heat it to 1650°C for high temperature melting, keep it warm for 1.0h, then cool it down to 1450°C at a rate of 10°C / min, and air-cool and quench to obtain crystallization and melting titanium slag .

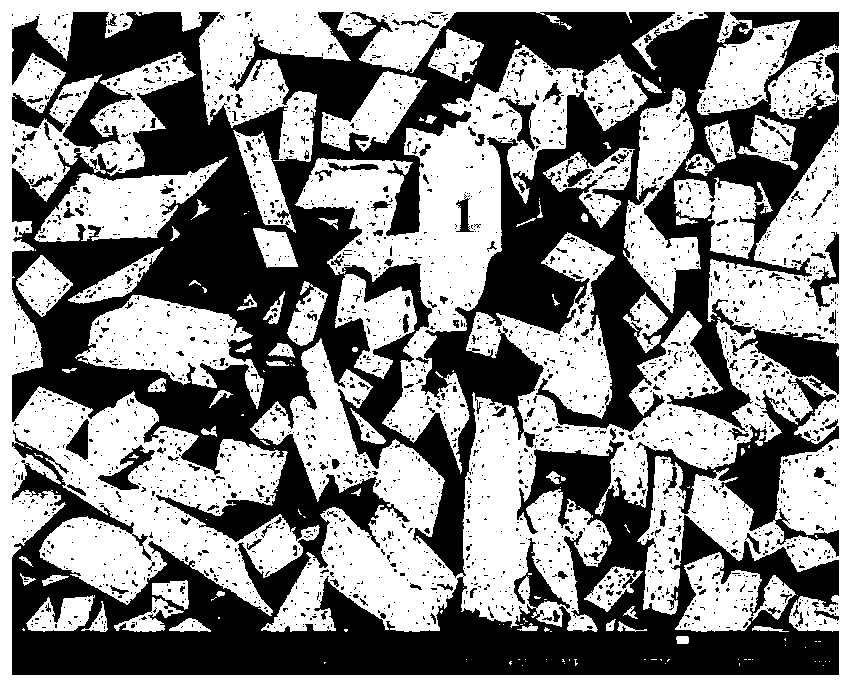

[0066] The morphology of the molten titanium slag was observed under a scanning electron microscope, such as image 3As shown, the slag only contains two phases of glass phase and black titanite, black titanite is the only titanium-rich phase, the structure is compact, and the interface with the glass phase is regular and round, and the weighted average particle size of black titanite is 61 μm. Using EDS to test the chemical composition of the titanium-rich phase of the molten titanium slag,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com