Energy-saving two-section type thermal treatment furnace for organic chemical industrial effluent

An organic chemical and heat treatment furnace technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of high cost, heat and energy loss, long time consumption, etc., and achieve a simple structure, easy operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

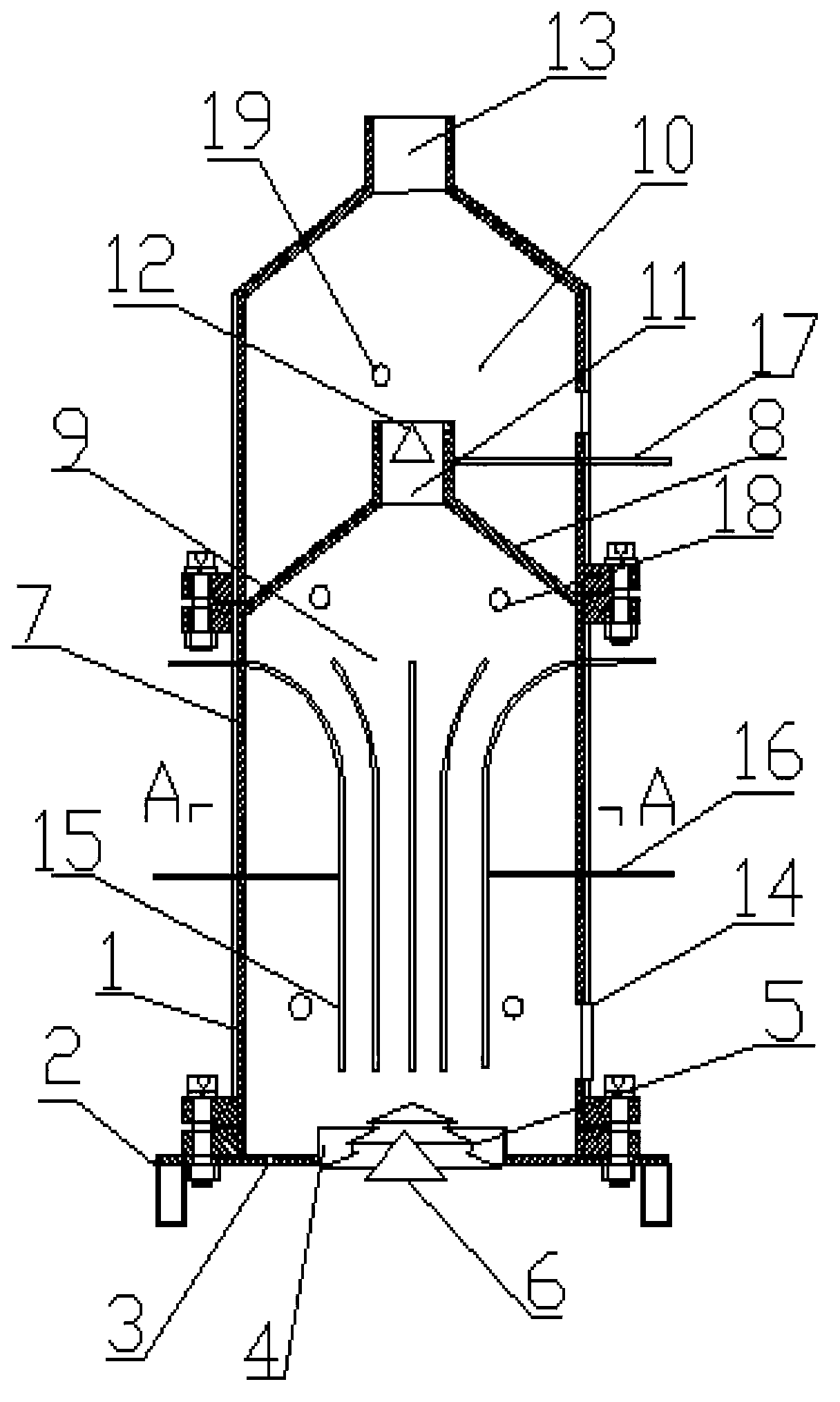

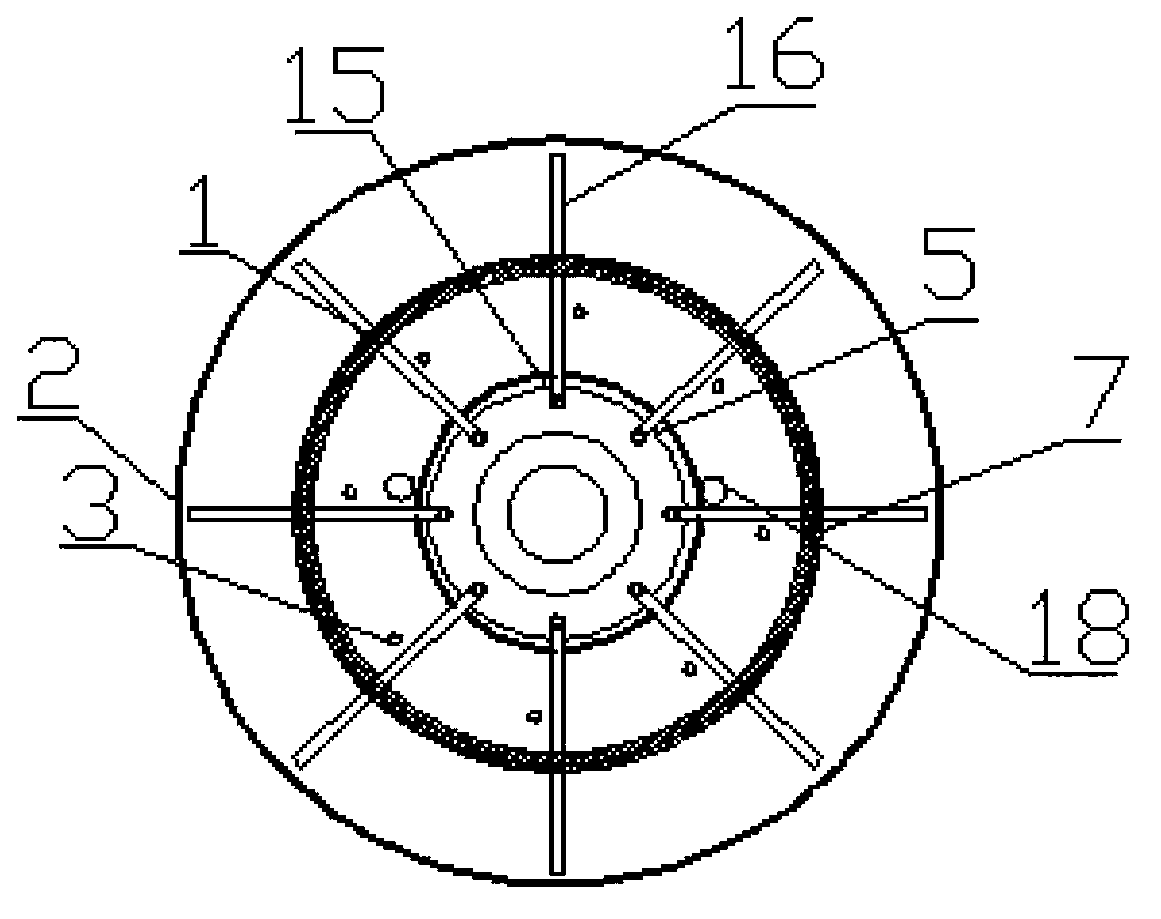

[0013] A two-stage organic chemical waste liquid heat treatment furnace, including a furnace body 1 and a furnace body support 2, the furnace body 1 is a vertical cylindrical structure, the ratio of the diameter to the height of the furnace body 1 is 1:5, and the furnace body support The top of 2 is a disc-shaped steel plate. Eight drainage holes 3 are uniformly distributed along the circumference of the steel plate. The center of the steel plate is provided with an ignition hole 4 and a ventilated umbrella-shaped protective cover 5 is fixed. A heating and ignition device is provided under the protective cover 5. 6. The furnace body 1 and the furnace body support 2 are connected by flanges, and an insulation layer 7 is provided outside the furnace body 1; the furnace body is composed of upper and lower sections and connected by flanges, and a cone A partition plate 8 divides the body of furnace 1 into a first combustion chamber 9 and a second combustion chamber 10. The height r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com