Vertical roller mill with material prepressing and positioned blanking and vertical roller milling method

A vertical roller mill and material technology, applied in grain processing and other directions, can solve problems such as affecting the chemical properties of materials and affecting the quality of cement, and achieve the effects of improving grinding efficiency, reducing mill vibration and shortening distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

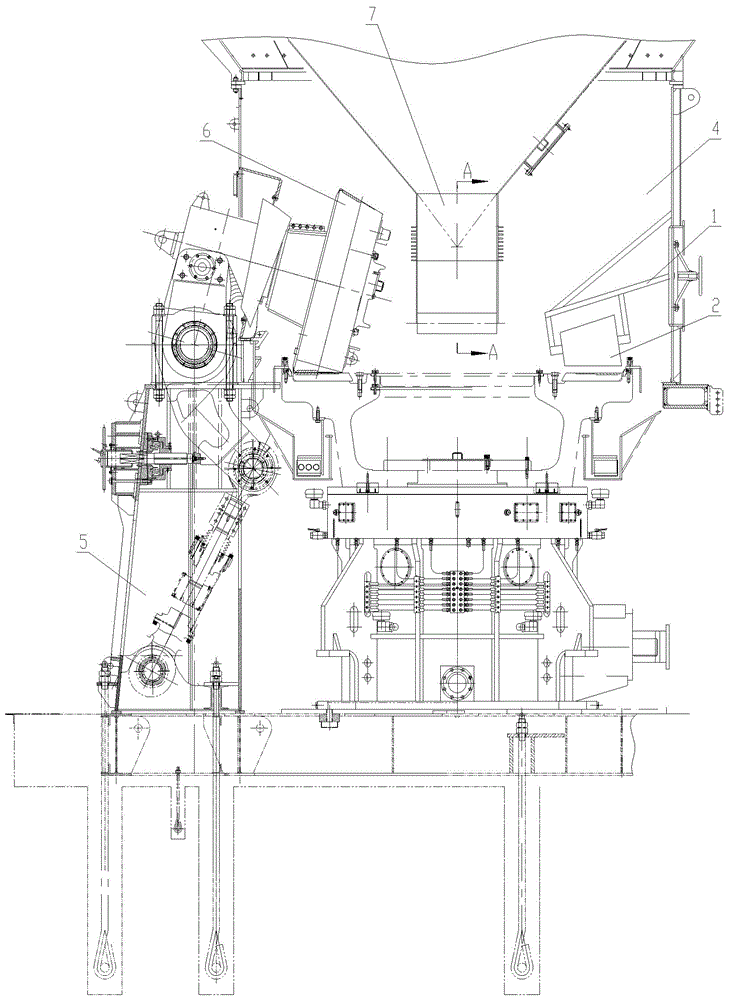

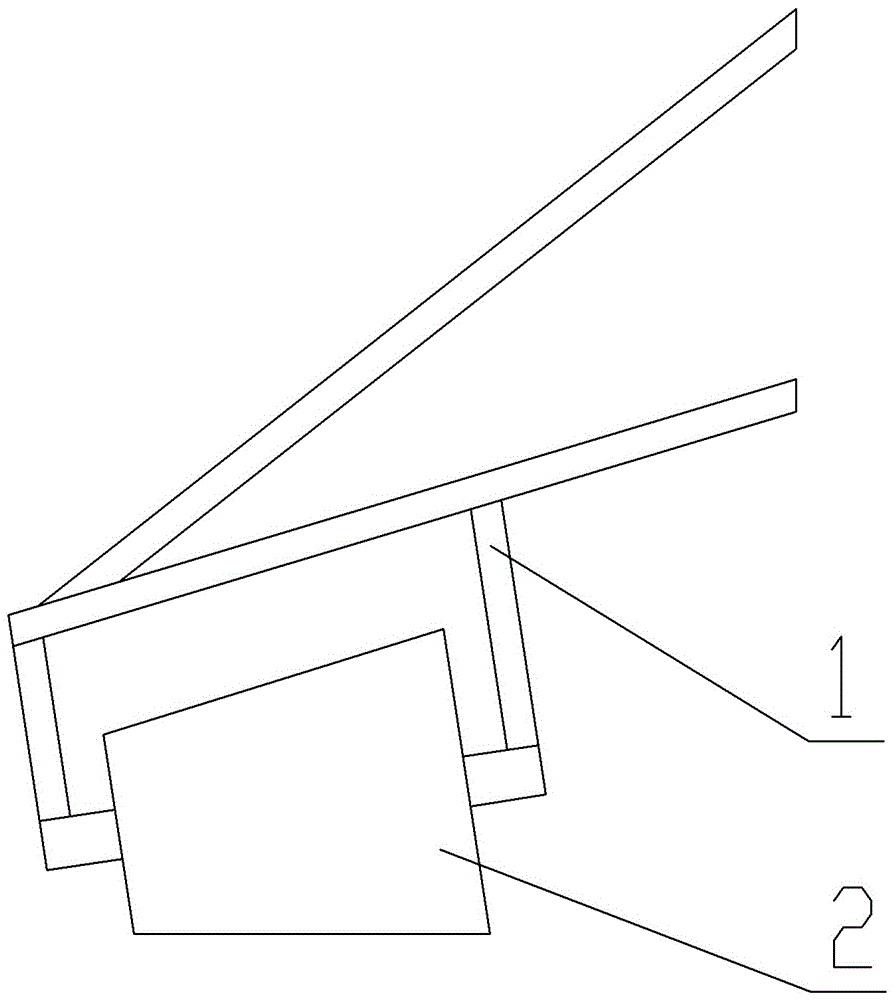

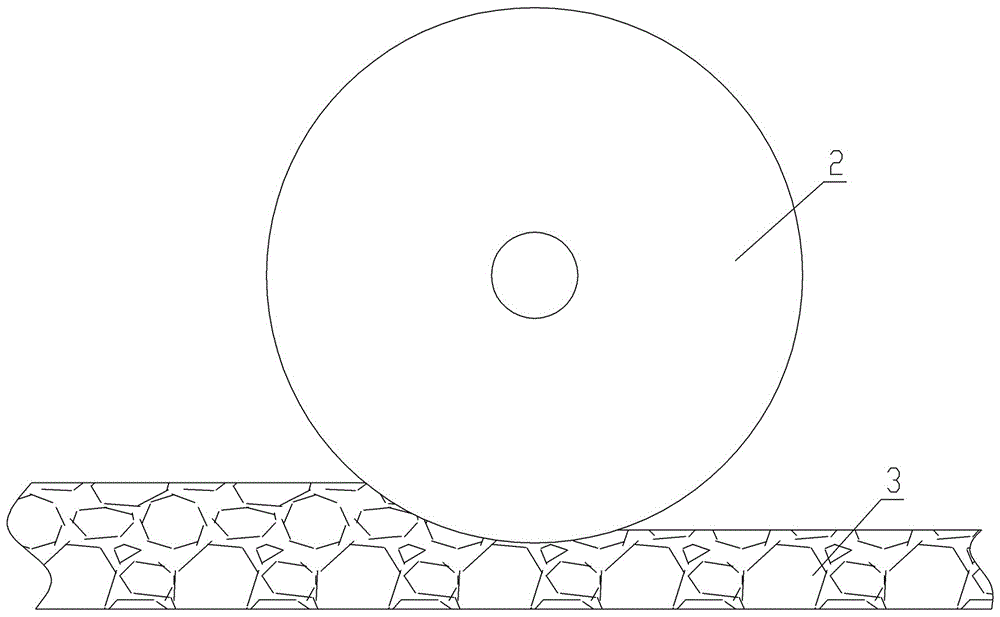

[0025] Example: see figure 1 -- Figure 4 , in the picture, 1-support frame, 2-rolling roller, 3-material, 4-grinding body, 5-support, 6-grinding roller, 7-centralized blanking device, 8-extended tube, 9-fixed plate , 10-connecting plate, 11-scraping plate.

[0026] Vertical roller mill with pre-pressed material and positioning blanking and vertical roller mill method: including grinding body 4, the inner cavity of grinding body 4 is provided with grinding disc, grinding roller 6 and inner cone bucket for blanking, grinding body The lower end of the 4 is provided with a support 5, and the inner cavity of the grinding body 4 is also provided with a material layer preloading device and a centralized blanking device 7. The material layer preloading device includes a rolling roller 2, and the two ends of the rolling roller 2 are provided with rotating The shaft, the rotating shaft is connected with the connecting rod through the bearing and the bearing seat, the connecting rod i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com