Small square blank vertical drawing continuous casting machine and pressing process device

A process device and a small billet technology, applied in the field of continuous casting production, can solve the problems of limited reduction capacity, inability to achieve efficient reduction, and low coverage of steel grades, and achieve the effect of improving the density of the center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

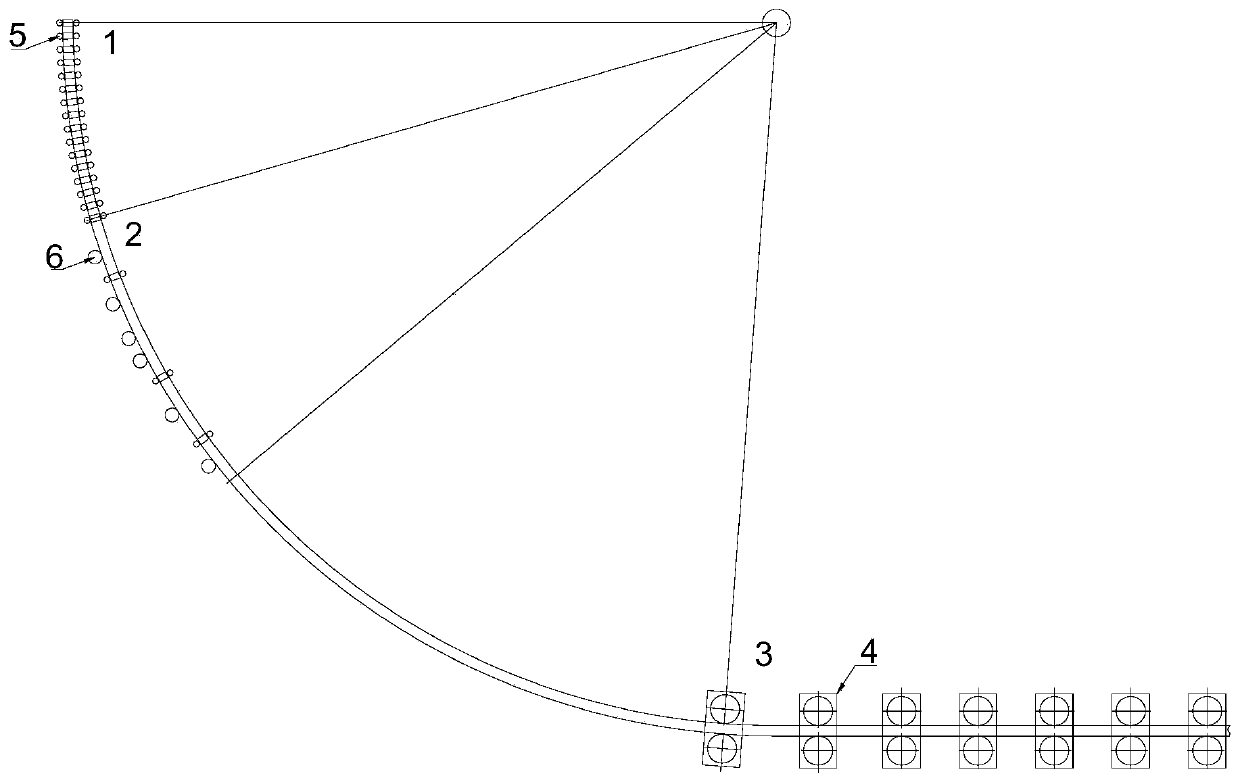

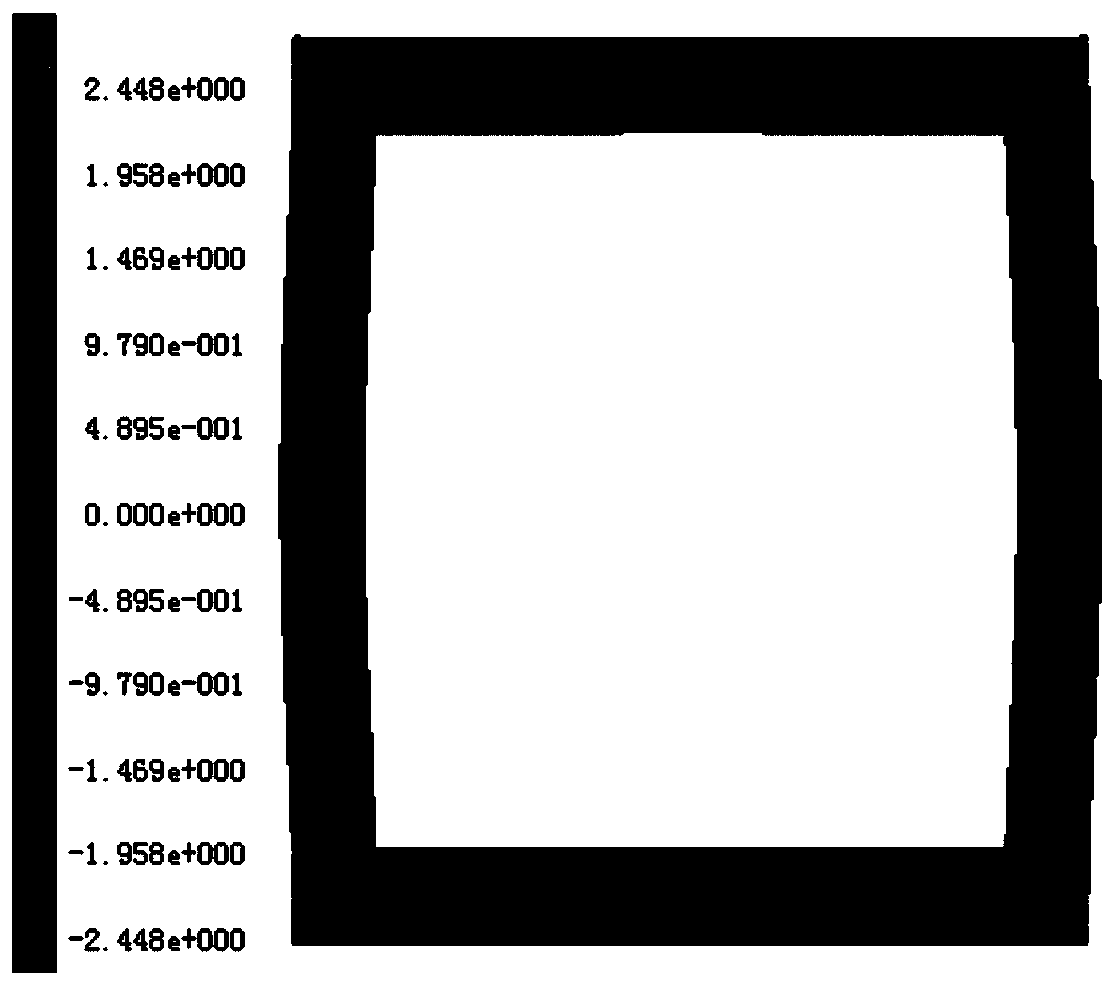

[0023] Such as figure 1 As shown, this example provides a kind of billet vertical casting machine and pressing process device, described billet vertical casting machine, such as figure 2 As shown at 2.3m away from the meniscus, since the billet shell thickness here is 15mm and the belly volume is 2.448mm, it is necessary to continuously implement four-sided clamping rolls on the foot roll section. That is, constraints are carried out in both the width and thickness directions of the slab.

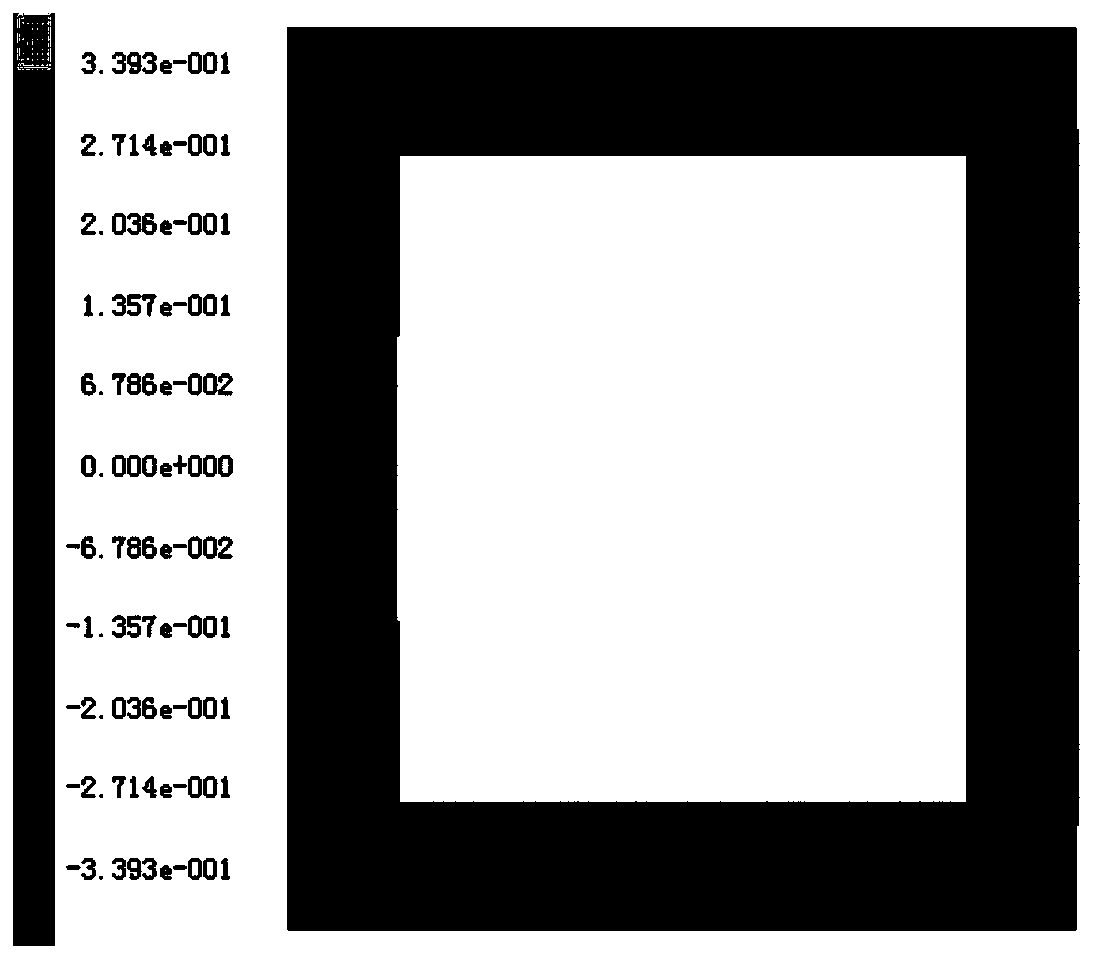

[0024] In the described billet vertical drawing continuous casting machine and the reduction process device, the secondary cooling zone 2 adopts segmented four-sided clamping of the casting roll 5, such as image 3 , 4 As shown at 3.8m and 5.3m from the meniscus, the thickness of the shells at the two places is 20mm and 25mm respectively, and the bulges are 0.339 and 0.0874mm respectively. Therefore, in order to further ensure the billet shape, the control of the bulges is arranged in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com